Method and system for large-scale production of anhydrous magnesium chloride

An anhydrous magnesium chloride, large-scale technology, applied in magnesium chloride, chemical instruments and methods, magnesium halide and other directions, can solve the problems of high demand for ammonia, organic solvents, large consumption of ammonia, equipment corrosion materials, etc., and reach the limit of raw material selection less, the effect of process continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

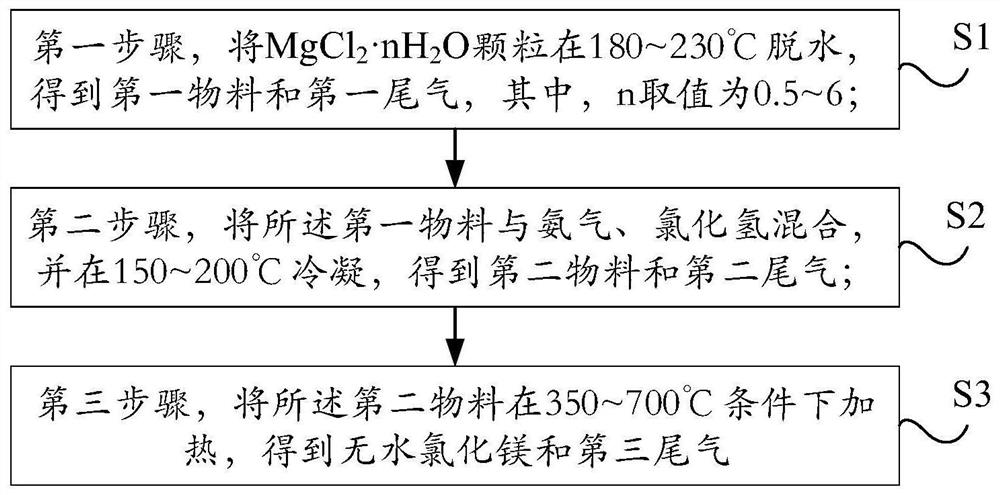

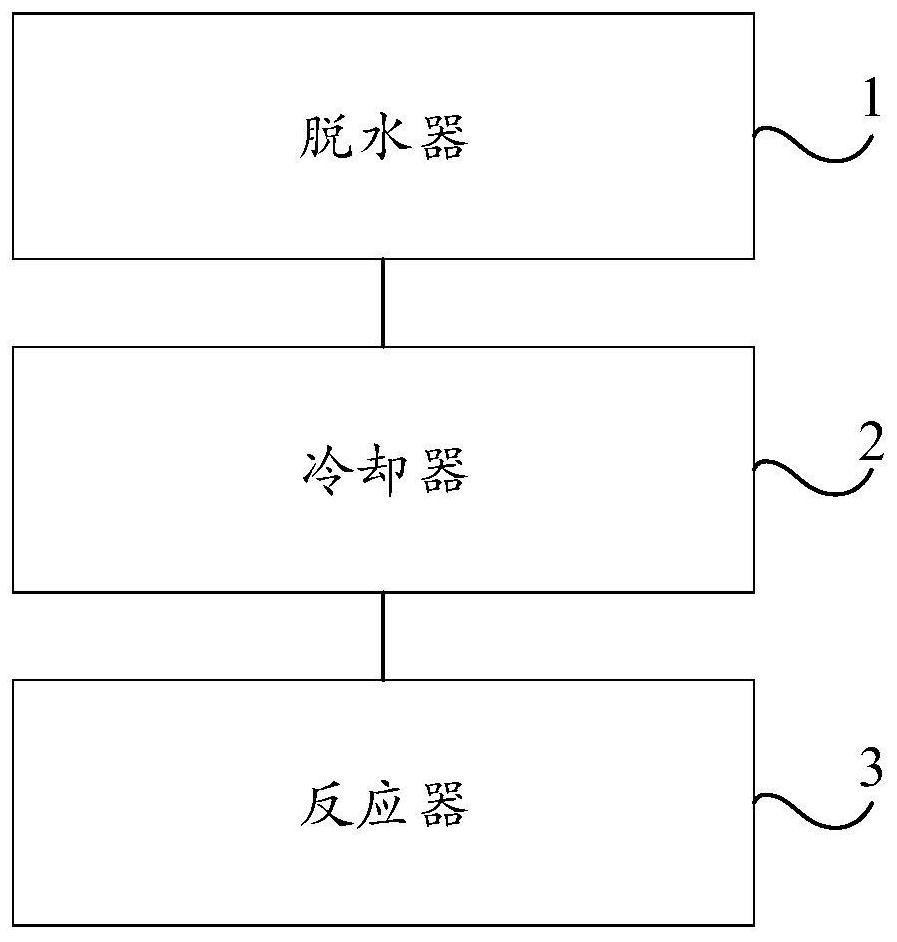

Method used

Image

Examples

Embodiment 1

[0065] Take 5 parts of MgCl 2 ·6H 2 O, each portion of 1000g, use a crusher to crush into granules, throw the crushed materials from the top of the dehydrator, make the granular materials fall from the top, and pass hot air into the bottom of the dehydrator to dehydrate them respectively The temperature in the container is kept at 170°C, 180°C, 200°C, 230°C, 240°C to obtain samples 1-6, and detect the molar ratio of chlorine to magnesium, and the molar ratio of hydrogen to magnesium in samples 1-6. ratio, as shown in Table 1.

[0066] Table 1.

[0067] sample 1 sample 2 sample 3 Sample 4 Sample 5 Chloride to magnesium ratio 1.928 1.833 1.563 1.247 1.090 Hydrogen to Magnesium Ratio 6.071 3.557 2.501 1.765 1.272

[0068] From the hydrogen-magnesium ratio and the chlorine-magnesium ratio, sample 1 contains a large amount of magnesium chloride trihydrate or tetrahydrate, most of samples 2 to 4 are magnesium chloride dihydrate and basi...

Embodiment 2

[0071] Take sample 3 and divide it into four parts. After co-condensing with ammonia and hydrogen chloride under the same conditions, they are transported to their respective reactors. In each reactor, the corresponding temperatures are respectively set to 350°C, 450°C, and 550°C. , 700°C, feed hydrogen chloride and ammonia gas so that the volume percentage of hydrogen chloride gas in the reactor is greater than 5%, and the mole of ammonia gas and hydrogen chloride gas in the reactor is 1.1, so that the gas atmosphere in the reactor is slightly alkaline , reacted for 3h, and after the reaction was completed, anhydrous magnesium chloride with a purity of 96.2%, 97.1%, 98.5% and 99.3% was obtained respectively through detection.

[0072] In the present invention, the ammonium chloride mixed with basic magnesium chloride is decomposed to increase the contact probability of hydrogen chloride and basic magnesium chloride, thereby promoting the reaction of the two, and obtaining rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com