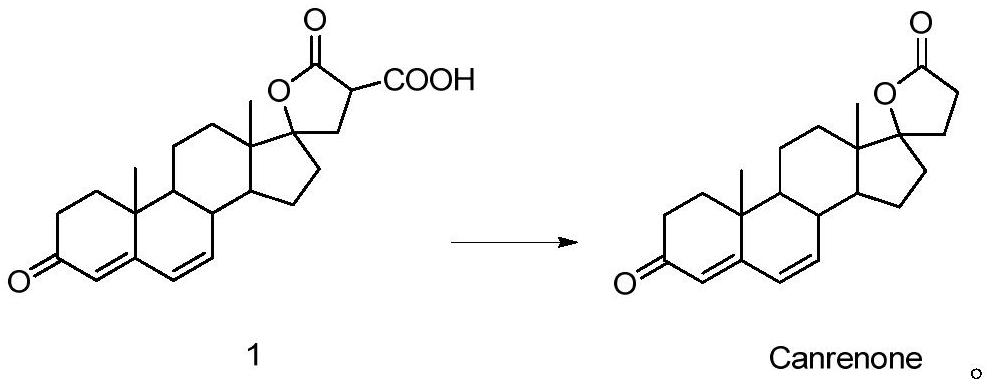

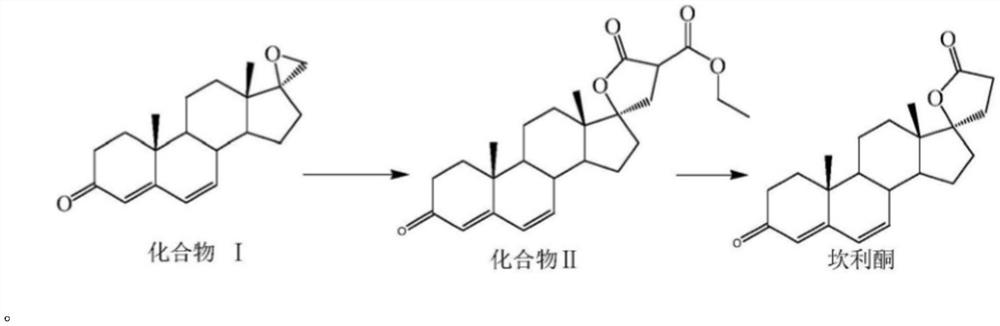

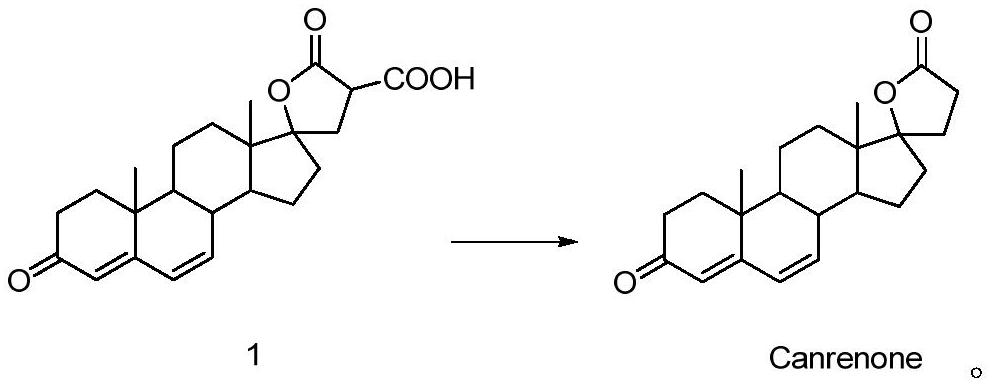

Synthesis method of canrenone

A synthetic method, the technology of canrenone, applied in the field of chemical synthesis, can solve the problems such as difficult to complete the reaction, long reaction time, and dangerous reaction, and achieve the effect of improving experimental operability, short time, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]

[0048] Material preparation:

[0049] Add 100g of compound 1, 500mL of ethylene glycol and 25mL of water into a 2L plastic beaker, mix them evenly, and stir to dissolve them.

[0050] System preparation:

[0051] Turn on the microchannel reaction system, set the temperature of the heat transfer oil in the preheating zone to 50°C, set the temperature of the reaction module in the reaction zone to 90°C, set the temperature of the heat transfer oil in the cooling zone to 20°C, and wait for the temperature to balance.

[0052] Preparation of canrenone:

[0053] After the temperature of the heat transfer oil is stable, use a convection pump to inject the prepared solution into the microchannel system at a rate of 10g / min. When the material flows out from the outlet of the cooling zone of the microchannel system, the residence time of the material is 5min after the system is stabilized. , carry out liquid chromatographic analysis on the outlet liquid of the reactor. Af...

Embodiment 2

[0055]

[0056] Material preparation:

[0057] Add 100g of compound 1, 800mL of DMSO and 50mL of water into a 2L plastic beaker, mix them evenly, and stir to dissolve them.

[0058] System preparation:

[0059] Turn on the microchannel reaction system, set the temperature of the heat transfer oil in the preheating zone: 30°C, set the temperature of the reaction module in the reaction zone to 120°C, set the temperature of the heat transfer oil in the cooling zone to 40°C, and wait for the temperature to balance.

[0060] Preparation of canrenone:

[0061] After the temperature of the heat transfer oil is stable, use a convection pump to inject the prepared solution into the microchannel system at a rate of 30g / min. When the material flows out from the outlet of the cooling zone of the microchannel system, the residence time of the material is 8 minutes after the system is stabilized. , carry out liquid chromatographic analysis on the outlet liquid of the reactor. After the...

Embodiment 3

[0063]

[0064] Material preparation:

[0065] Add 100g of compound 1, 1000mL of NMP and 100mL of water into a 2L plastic beaker, mix them evenly, and stir to dissolve them.

[0066] System preparation:

[0067] Turn on the microchannel reaction system, set the temperature of the heat transfer oil in the preheating zone to 25°C, set the temperature of the reaction module in the reaction zone to 140°C, set the temperature of the heat transfer oil in the cooling zone to 20°C, and wait for the temperature to balance.

[0068] Preparation of canrenone:

[0069] After the temperature of the heat transfer oil is stable, the prepared solution is pumped into the micro-channel system at a rate of 50g / min with an advection pump. When the material flows out from the outlet of the cooling zone of the micro-channel system, the residence time of the material is 1min after the system is stabilized. , carry out liquid chromatographic analysis on the outlet liquid of the reactor. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com