High-temperature-resistant transparent polyester film and preparation method thereof

A technology of polyester film and high temperature resistance, applied in the field of polyester film, can solve the problems of expensive PI film, difficult application in high temperature environment, electronic button failure, etc., achieve good chemical resistance, oil resistance, and good transparency , good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

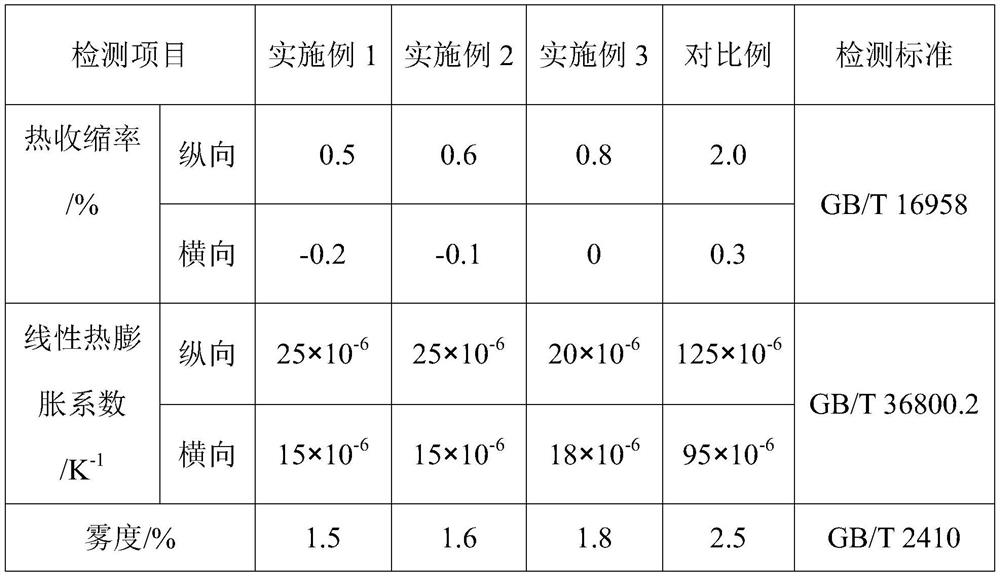

Examples

Embodiment 1

[0031] A kind of high temperature resistant transparent polyester film that the present invention proposes, its thickness is 15 μ m, comprises polyester core layer and the upper surface layer and the lower surface layer laminated on the surface of polyester core layer, wherein the thickness of the upper and lower surface layer is respectively 1 / 3 of the film thickness 12%;

[0032] The core layer is made of the following raw materials in weight percentage: 5% of submicron glass fiber, 0.1% of interfacial coupling agent, and 94.9% of PET chips; wherein, the interfacial coupling agent is vinyltriethoxysilane and methacrylic acid chloride A mixture of chromium salts in a weight ratio of 1:1;

[0033] The composition of the upper and lower surface layers is the same, consisting of the following raw materials in weight percentage: 5% of anti-adhesive masterbatch, 65% of PET slices, and 30% of PEN slices; among them, the effective anti-adhesive particles of the anti-adhesive masterb...

Embodiment 2

[0039] A high temperature resistant transparent polyester film proposed by the present invention has a thickness of 30 μm, including a polyester core layer and an upper surface layer and a lower surface layer laminated on the surface of the polyester core layer, wherein the thicknesses of the upper and lower surface layers are respectively 1 / 3 of the film thickness 13%;

[0040] The core layer is made of the following raw materials in weight percentage: 8% of submicron glass fiber, 1.5% of interfacial coupling agent, and 90.5% of PET chips; wherein, the interfacial coupling agent is vinyltriethoxysilane and methacrylic acid chloride A mixture of chromium salts in a weight ratio of 1:1;

[0041] The composition of the upper and lower surface layers is the same, consisting of the following raw materials in weight percentage: 8% of anti-adhesive masterbatch, 70% of PET slices, and 22% of PEN slices; among them, the effective anti-adhesive particles of the anti-adhesive masterbatc...

Embodiment 3

[0044] A high temperature resistant transparent polyester film proposed by the present invention has a thickness of 50 μm, comprising a polyester core layer and an upper surface layer and a lower surface layer laminated on the surface of the polyester core layer, wherein the thicknesses of the upper and lower surface layers are respectively 1 / 3 of the film thickness 14%;

[0045] The core layer is made of the following raw materials in weight percentage: 10% of submicron glass fiber, 2.5% of interfacial coupling agent, and 87.5% of PET chips; among them, the interfacial coupling agent is vinyltriethoxysilane and tetrabutyl titanate A mixture of esters in a weight ratio of 1:1;

[0046] The composition of the upper and lower surface layers is the same, consisting of the following raw materials in weight percentage: 10% of anti-adhesive masterbatch, 60% of PET slices, and 30% of PEN slices; among them, the effective anti-adhesive particles of the anti-adhesive masterbatch are gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com