Molecular sieve catalytic inorganic fiber, preparation method and dedusting and denitration integrated application thereof

An inorganic fiber and molecular sieve technology, which is applied in the field of flue gas purification, can solve the problems of complex synthesis method of catalytic filter material, unfavorable for large-scale popularization and use, and limitation of catalyst types. Effect of Sulfur Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a method for preparing molecular sieve catalyzed inorganic fibers, the preparation method comprising the following steps:

[0090] (1) Pretreatment of inorganic fibers:

[0091] Take a certain amount of aluminum silicate fiber and immerse it with ethanol first, not only can effectively remove the oil on the inorganic fiber, but also make the bead-shaped high-density impurities mixed in the inorganic fiber sink to the bottom to remove, and then use ethanol After a brief rinse, dry overnight in an oven at 80°C;

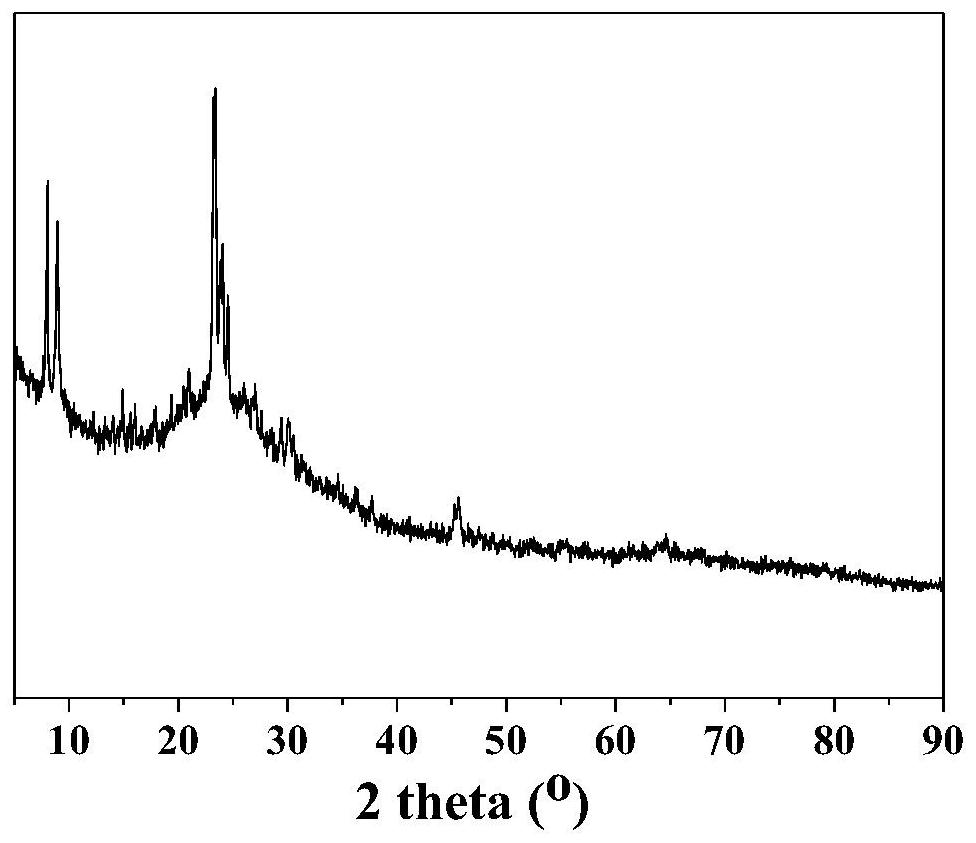

[0092] (2) Preparation of MFI type molecular sieve precursor solution:

[0093] According to the molar ratio of ethyl orthosilicate, sodium metaaluminate, tetrapropyl sodium hydroxide and deionized water as 25:1:5:1000, each component was weighed and mixed to obtain MFI type molecular sieve Precursor solution;

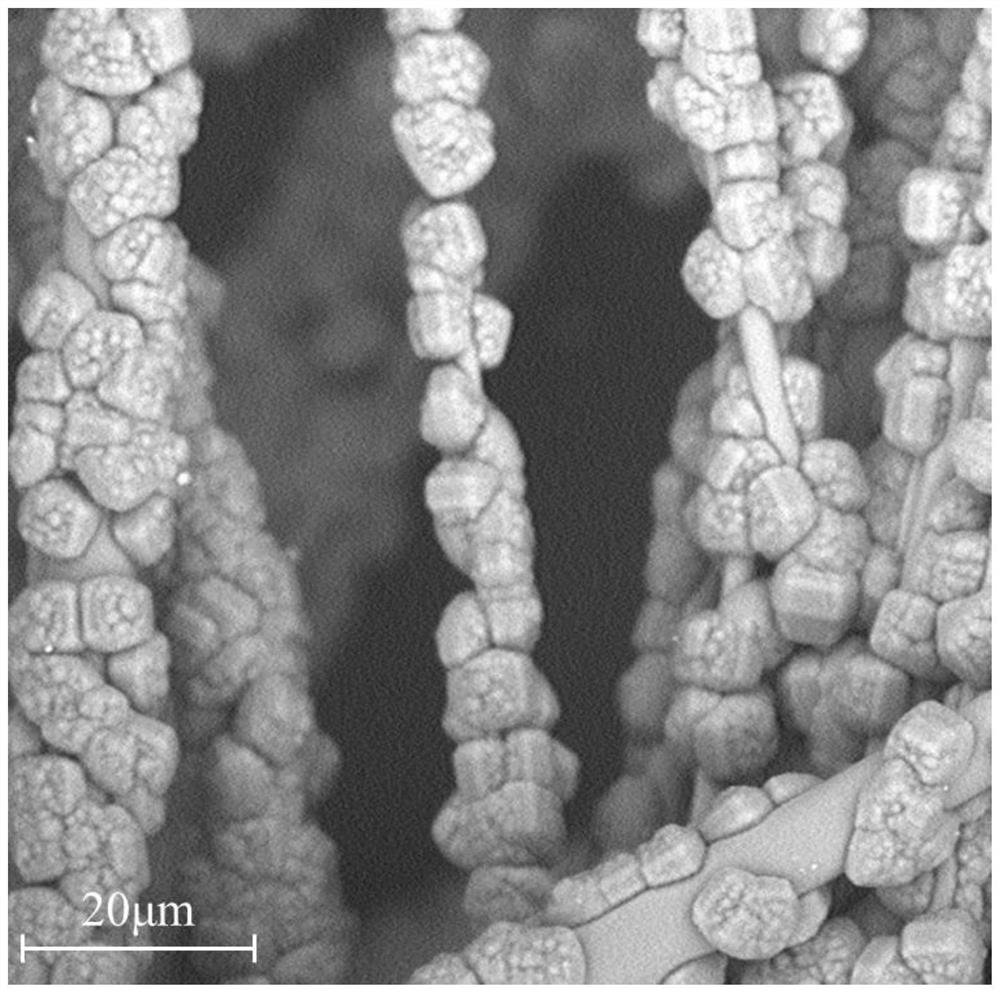

[0094] (3) Hydrothermal synthesis of inorganic fibers catalyzed by molecular sieves:

[0095] Submerge the aluminum silicate...

Embodiment 2

[0101] This embodiment provides a method for preparing molecular sieve catalyzed inorganic fibers, the preparation method comprising the following steps:

[0102] (1') carry out pretreatment to inorganic fiber:

[0103] Take a certain amount of basalt fiber and immerse it with ethanol first, not only can effectively remove the oil stain on the inorganic fiber, but also make the bead-shaped high-density impurities mixed in the inorganic fiber sink to the bottom to be removed, and then simply rinse with ethanol Afterwards, dry overnight in an oven at 80°C;

[0104] (2') Preparation of metal ion type molecular sieve precursor solution:

[0105] According to the molar ratio of ethyl orthosilicate, sodium metaaluminate, copper nitrate, tetrapropyl sodium hydroxide and deionized water is 25:1:0.005:5:1000, weigh each component respectively, and mix them Finally, the metal ion type molecular sieve precursor solution is obtained;

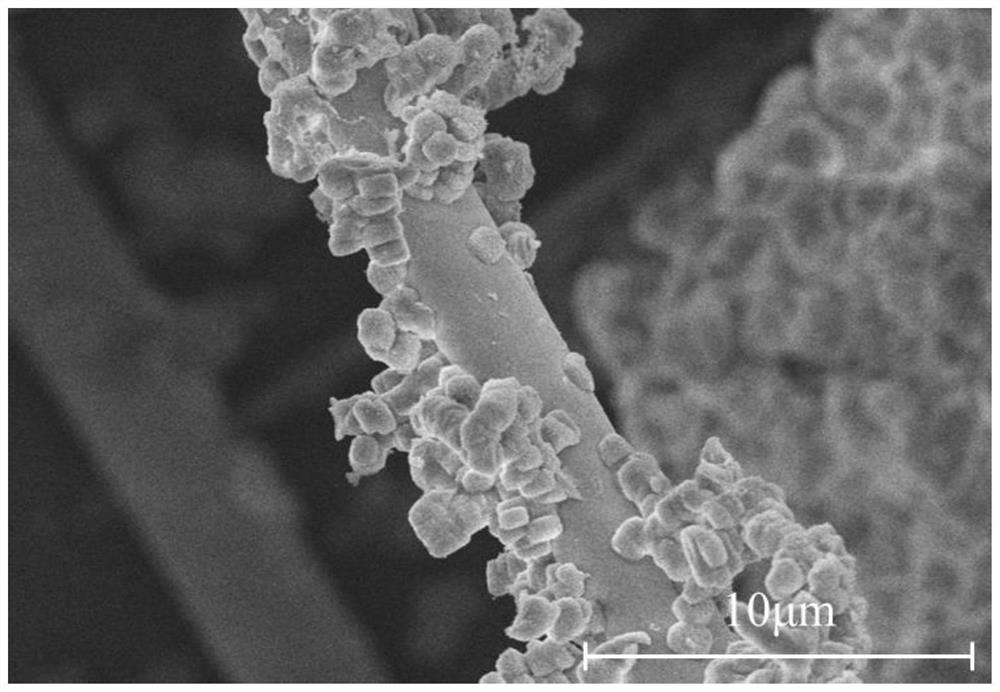

[0106] (3') Molecular sieve catalyzed hydrothermal...

Embodiment 3

[0114] This embodiment provides a method for preparing molecular sieve catalyzed inorganic fibers, the preparation method comprising the following steps:

[0115] (1') carry out pretreatment to inorganic fiber:

[0116] Take a certain amount of mullite fiber and immerse it with ethanol first, not only can effectively remove the oil on the inorganic fiber, but also make the bead-shaped high-density impurities mixed in the inorganic fiber sink to the bottom and be removed, and then use ethanol After a brief rinse, dry overnight in an oven at 80°C;

[0117] (2') Preparation of metal ion type molecular sieve precursor solution:

[0118] According to the molar ratio of ethyl orthosilicate, sodium metaaluminate, copper nitrate, tetrapropyl sodium hydroxide and deionized water is 5:1:0.005:5:500, weigh each component respectively, and mix them Finally, the metal ion type molecular sieve precursor solution is obtained;

[0119] (3') Molecular sieve catalyzed hydrothermal synthesis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com