A kind of cerium-based denitrification catalyst and its preparation process

A denitration catalyst and oxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of narrow reaction temperature window and poor low temperature activity, etc. Achieve the effect of good low temperature reactivity and stability, enhanced water and sulfur resistance, and strong water and sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

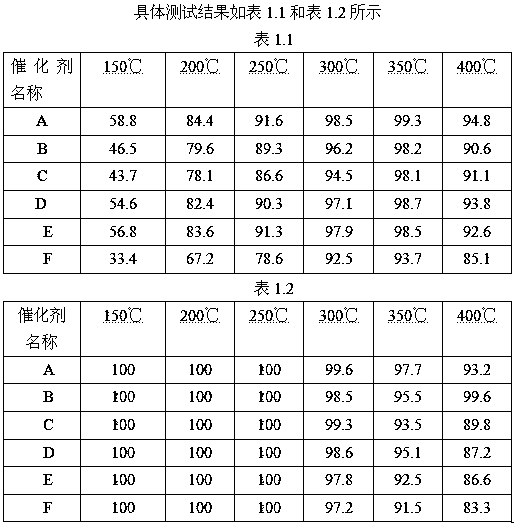

Examples

Embodiment 1

[0026] 1) Dissolve cerium nitrate in deionized water, stir at room temperature for 10 minutes to dissolve completely, then add antimony trichloride and polyvinylpyrrolidone and continue stirring for 0.5h to fully mix to obtain a mixed solution, in which polyvinylpyrrolidone Accounting for 0.5wt% of the total weight of the metal precursor, the molar concentrations of cerium and antimony elements in the mixed solution are 0.1 mol / L and 0.1 mol / L, respectively;

[0027] 2) Add hexamethylenetetramine, which accounts for 2 times the total weight of the metal precursor, to the mixed solution obtained in step 1), stir it for 30 minutes to make it fully mixed, and then transfer it to a hydrothermal reaction kettle for 24 hours at 140°C. The cerium and antimony ions are fully and uniformly settled, and then naturally cooled to room temperature to obtain a mixture containing the precipitate, and the mixture containing the precipitate is filtered to obtain the primary precipitate;

[002...

Embodiment 2

[0032] 1) Dissolve cerium nitrate in deionized water, stir at room temperature for 20 minutes to completely dissolve, then add antimony acetate and morpholine and continue stirring for 3.0 hours to fully mix to obtain a mixed solution, in which morpholine accounts for the metal precursor 3.0wt% of the total weight, the molar concentrations of cerium and antimony elements in the mixed solution are 1mol / L and 2mol / L respectively;

[0033] 2) Add hexamethylenetetramine accounting for 5 times the total weight of the metal precursor to the mixed solution obtained in step 1), stir it for 60 minutes to make it fully mixed, and then transfer it to a hydrothermal reaction kettle for 12 hours at 200°C. The cerium and antimony ions are fully and uniformly settled, and then naturally cooled to room temperature to obtain a mixture containing the precipitate, and the mixture containing the precipitate is filtered to obtain the primary precipitate;

[0034] 3) Add 30% hydrogen peroxide to th...

Embodiment 3

[0038] 1) Dissolve ammonium cerium nitrate in deionized water, stir at room temperature for 12 minutes to completely dissolve, then add antimony trichloride and sodium dodecylbenzenesulfonate and continue to stir for 2.0 hours to fully mix to obtain a mixed solution , wherein sodium dodecylbenzenesulfonate accounts for 1.0wt% of the total weight of the metal precursor, and the molar concentrations of cerium and antimony elements in the mixed solution are 2 mol / L and 3 mol / L, respectively;

[0039]2) Add hexamethylenetetramine accounting for 3 times the total weight of the metal precursor to the mixed solution obtained in step 1), stir it for 40 minutes to make it fully mixed, and then transfer it to a hydrothermal reaction kettle for 22 hours at 160°C. The cerium and antimony ions are fully and uniformly settled, and then naturally cooled to room temperature to obtain a mixture containing the precipitate, and the mixture containing the precipitate is filtered to obtain the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com