A kind of coke oven flue gas low temperature denitration catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor water and sulfur resistance of Mn-based catalysts, insufficient catalyst denitration rate, and high price. Achieve the effect of inhibiting SO2 oxidation, low production cost, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

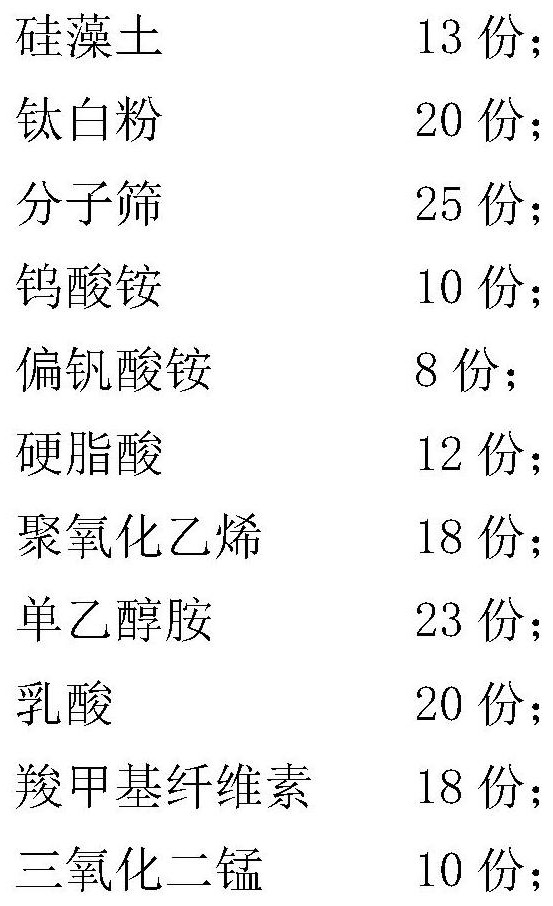

[0032] A low-temperature denitrification catalyst for coke oven flue gas, prepared from the following raw materials in parts by weight:

[0033]

[0034]

[0035] The preparation method of the above coke oven flue gas low-temperature denitrification catalyst, the steps are as follows:

[0036] 1) Dry diatomaceous earth, titanium dioxide, and molecular sieves in a vacuum oven at 60°C for 8 hours, and cool down to room temperature;

[0037] 2) Add ammonium tungstate and ammonium metavanadate to the mixing tank, mix with a certain amount of water and stir at a speed of 100r / min for 2 hours, then add diatomite, titanium dioxide and molecular sieve pretreated in step 1) , continue to stir for 2h;

[0038] 3) placing the stirred product in step 2) in a muffle furnace, and calcining at 300° C. for 5 hours to obtain the corresponding oxide active centers tungsten trioxide and vanadium pentoxide;

[0039] 4) adding stearic acid, polyoxyethylene, monoethanolamine, lactic acid, c...

Embodiment 2

[0047] The preparation method and product are the same as in Example 1, only the composition of the simulated flue gas is changed, and the application is as follows:

[0048] Taking 0.50g of the catalyst of the present invention as the experimental object, within the temperature range of 240-300°C, the space velocity is 3500h -1 , the simulated flue gas composition is: 1000ppm NO, NH 3 / NO=1.1, 5%O 2 , 400ppm SO 2 , 10%H 2 O, the balance gas is N 2 , its denitrification efficiency is 95% at 240°C and 96.8% at 300°C.

Embodiment 3

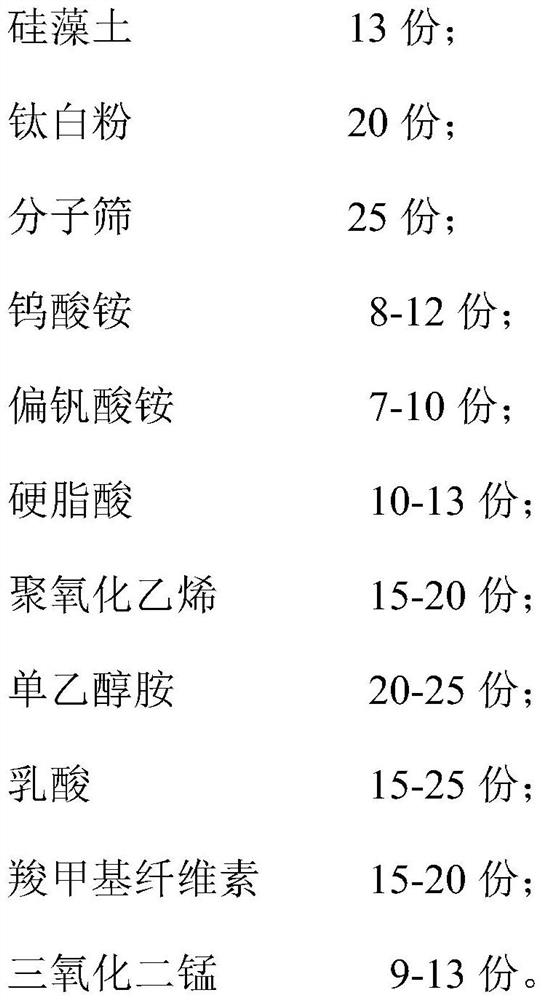

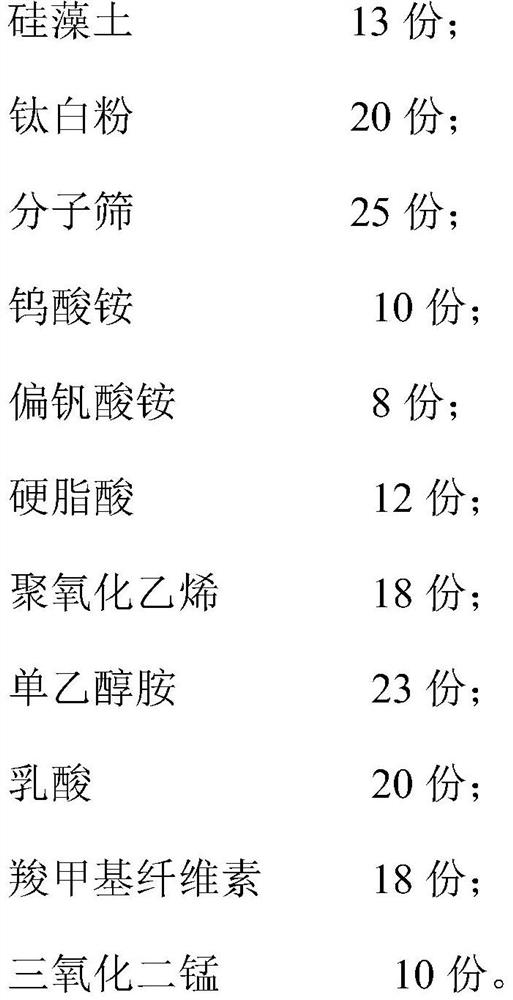

[0050] A low-temperature denitrification catalyst for coke oven flue gas, prepared from the following raw materials in parts by weight:

[0051]

[0052] The preparation method of the above coke oven flue gas low-temperature denitrification catalyst, the steps are as follows:

[0053] 1) Dry diatomaceous earth, titanium dioxide, and molecular sieves in a vacuum oven at 80°C for 3 hours, and cool down to room temperature;

[0054] 2) Add ammonium tungstate and ammonium metavanadate to the mixing tank, mix with a certain amount of water and stir at a speed of 200r / min for 1 hour, then add diatomite, titanium dioxide and molecular sieve pretreated in step 1) , continue to stir for 1h;

[0055] 3) placing the stirred product in step 2) in a muffle furnace, and calcining at 500° C. for 3 hours to obtain the corresponding oxide active centers tungsten trioxide and vanadium pentoxide;

[0056] 4) adding stearic acid, polyoxyethylene, monoethanolamine, lactic acid, carboxymethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com