Flexible sensing material with adaptive piezoresistive performance and preparation method and application thereof

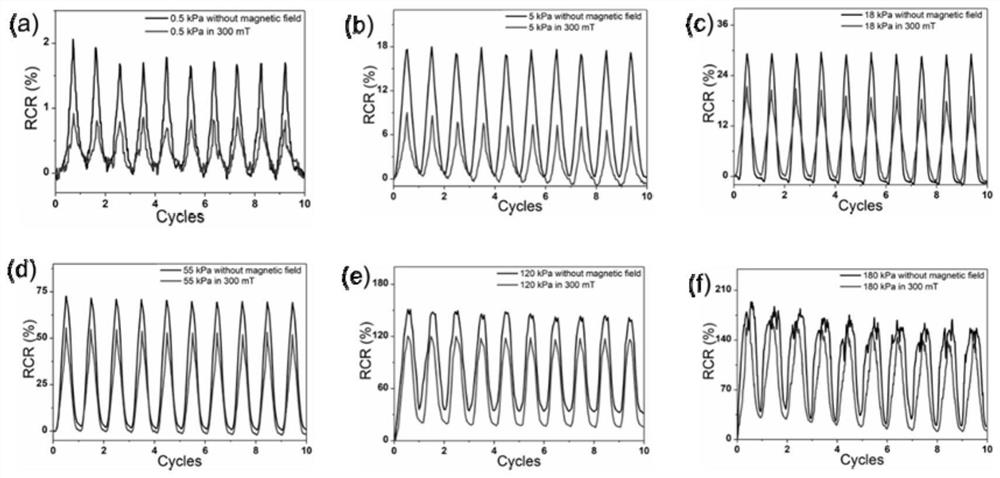

A sensing material and flexible technology, applied in the field of flexible piezoresistive composite materials, the preparation of flexible piezoresistive sensor materials, and materials for sensors, which can solve the piezoresistive performance response sensitivity adjustment, wide working range, and no elastomer material found. problems, to achieve the effect of improving the effective working range and improving the piezoresistive response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Materials: Silicone resin (Ecoflex 00-20, Parts A and B) was provided by Smooth-On, Inc.; magnetic carbonyl iron particles (CIP) were obtained from Nangong Xindun Alloy Welding Material Spraying Co., Ltd.; Kanghao Polymer Science Ltd. purchased melamine sponges.

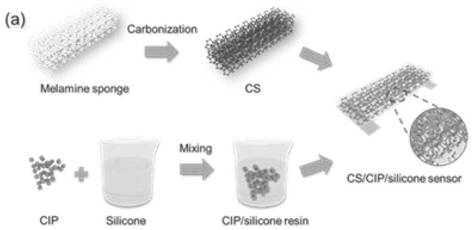

[0053] method:

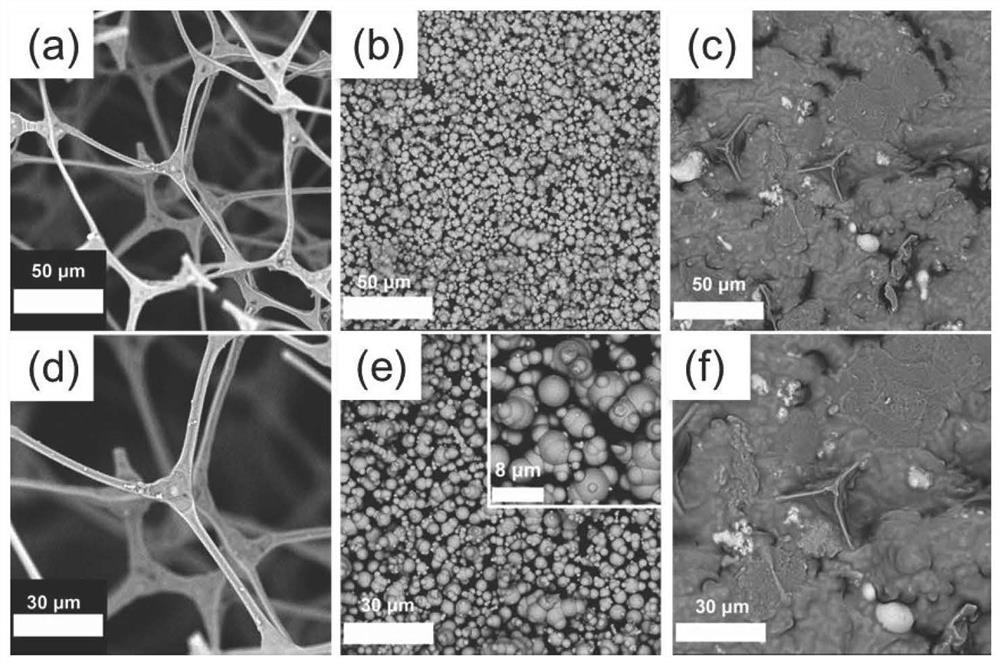

[0054] Commercially produced polymelamine foam is carbonized at high temperature by high-temperature carbonization method to prepare carbon foam material (CS) with three-dimensional conductive network structure. Specifically, the organic foam material is washed in ethanol to remove impurities, dried and placed in a tube furnace, under the protection of an inert gas and at 800 ° C, in N 2 After carbonizing in the atmosphere for 2 hours, cool down to room temperature under the protection of inert gas, and then cut into 40×11×3.5mm 3 shape, made of carbon sponge (CS).

[0055] A series of proportions of carbonyl iron particles (CIP) and silicone resin are uniformly dispersed, and the composite...

Embodiment 2

[0059] Materials: MDI and polyether were provided by Yantai Wanhua; carbonyl nickel powder was obtained from Weifang Kena Powder Metallurgy Factory; phenolic resin foam was purchased from Shandong Shengquan Chemical Co., Ltd.

[0060] method:

[0061] A high-temperature carbonization method is used to carbonize phenolic resin foam obtained from commercial channels at high temperature to prepare a carbon foam material with a three-dimensional conductive network structure. Specifically, the organic foam material is washed in ethanol to remove impurities, dried and placed in a tube furnace, under the protection of an inert gas and at 900 ° C, carbonized in a He atmosphere for 2 hours, then cooled to room temperature under the protection of an inert gas, and then Cut into 40×11×3.5mm 3 shape, made of carbon sponge.

[0062] A certain proportion of nickel carbonyl particles and MDI are compounded and dispersed evenly, then polyether is added, and then the composite fluid is impre...

Embodiment 3

[0064] Materials: Natural rubber latex was provided by Shanghai Liankangming Chemical Co., Ltd.; cobalt carbonyl powder was obtained from McLean; starch plastic foam was purchased from the market.

[0065] method:

[0066] A high-temperature carbonization method is used to carbonize starch plastic foam obtained from commercial channels at high temperature to prepare a carbon foam material with a three-dimensional conductive network structure. Specifically, the organic foam material is washed in ethanol to remove impurities, dried and placed in a tube furnace, under the protection of an inert gas and at 900 ° C, in N 2 After carbonizing in the atmosphere for 2 hours, cool down to room temperature under the protection of inert gas, and then cut into 40×11×3.5mm 3 shape, made of carbon sponge.

[0067] Compound and disperse a certain proportion of cobalt carbonyl particles and natural rubber latex evenly, then add a vulcanizing agent, and then impregnate the composite fluid int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com