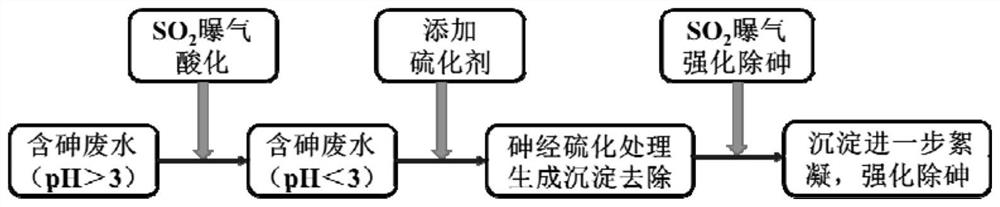

Method for strengthening sulfidizing treatment of arsenic-containing wastewater by utilizing sulfur dioxide

A technology for sulfur dioxide and sulfurization treatment, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of low arsenic removal efficiency, high cost, secondary pollution, etc. Arsenic efficiency, enhanced stability, good effect of waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, a set of sulfidation and arsenic removal devices equipped with gaseous hydrogen sulfide as a sulfidation agent from an actual copper smelter includes a volume of 30m 3 A sealed cylindrical autoclave and a volume of 30m 3 A sealed cylindrical exhaust gas treatment tank. Among them, the pH of the wastewater treated by the vulcanization tank is 7, the concentration of arsenic is 10000mg / L, and the treatment volume is 20m 3 For waste water, the concentration of hydrogen sulfide gas used is 50%, and the flow rate is 500m 3 / h, the treatment time is 1 hour, and the arsenic removal efficiency is about 40%. Switch to SO2-enhanced method, first, use 5% SO2 gas at 120m 3 The flow rate of / h is aerated for 20min. At this time, the pH of the wastewater drops to about 2.7, and then 50% hydrogen sulfide gas is used to 3 / h flow aeration for 1 hour, at this time, the arsenic removal efficiency reaches 95%, stop feeding hydrogen sulfide gas, and reuse 5% sulfur ...

Embodiment 2

[0034] A lead smelter is equipped with a sulfidation arsenic removal device using sodium sulfide as the sulfidation agent, which includes a 50m 3 A sealed cylindrical autoclave and a volume of 30m 3 A sealed cylindrical exhaust gas treatment tank. Among them, the vulcanization tank is equipped with a stirring device, the pH of the treated wastewater is 4, the concentration of arsenic is 3000mg / L, and the treatment volume is 30m 3 For waste water, the sodium sulfide liquid concentration used is 20%, adding 3m each time 3 , the treatment time is 1 hour, and the arsenic removal efficiency is about 50%. Switch to SO2-enhanced method, first, use 5% SO2 gas at 120m 3 The flow rate of / h is aerated for 20 minutes. At this time, the pH of the wastewater drops to about 2.3. After injecting sodium sulfide solution for 1 hour, re-use 5% sulfur dioxide gas at 120m 3 The flow rate of / h is aerated for 2 hours. At this time, the pH of the wastewater is about 2, and the arsenic removal e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com