High-capacity single-crystal positive electrode material and preparation method thereof

A cathode material and high-capacity technology, which is applied in the field of high-capacity single-crystal cathode materials and their preparation, can solve the problems of reducing irreversible capacity, achieve the effects of reducing irreversible capacity, improving stability, and inhibiting cation mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

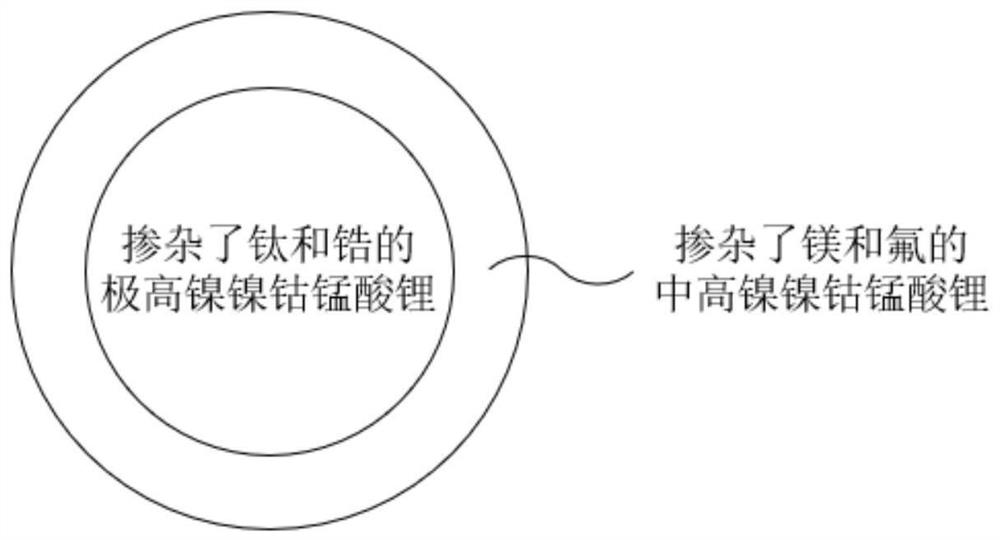

[0047] (1) Mixing: prepare high-nickel-nickel-cobalt-manganese ternary precursor powder a (the molar ratio of nickel-cobalt-manganese is 8.1:1:0.9) and b (the molar ratio of nickel-cobalt-manganese is 6:2:2), a and b The molar ratio is 10:1, add a part weight of 0.1wt% titanium dioxide and 0.8wt% zirconia powder and lithium carbonate powder (Li / M a =1.08) mixed in a ball mill for 24h to obtain mixed powder A; add b parts of 0.4wt% magnesium oxide and 0.1wt% lithium fluoride powder and lithium carbonate powder (Li / M b =1.18) mixed in a ball mill for 16h to obtain mixed powder B;

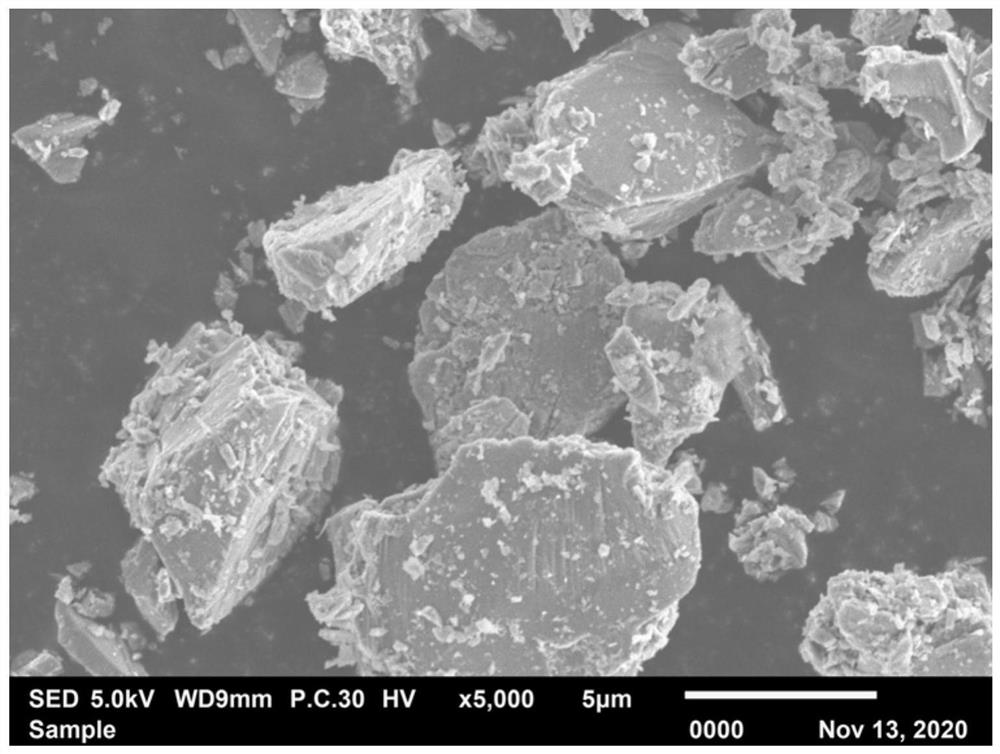

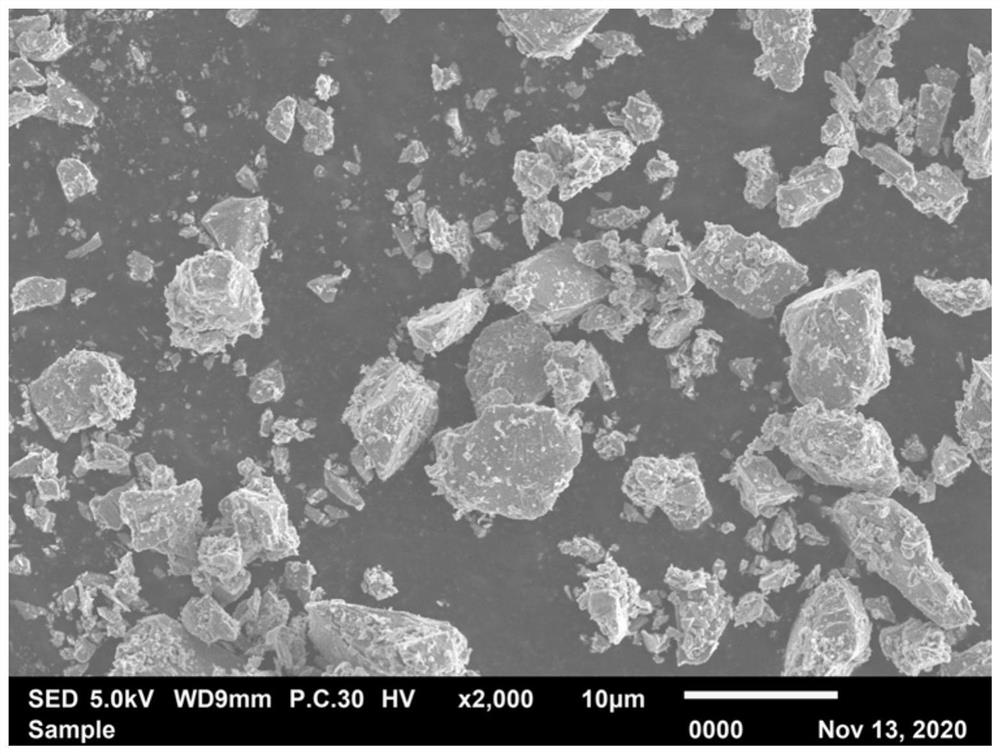

[0048] (2) Primary sintering: Put the mixed powder A obtained in step (1) into a tube furnace and heat it to 780°C at a heating rate of 2°C / min, and keep it warm for 12 hours. During this period, an oxygen atmosphere is introduced at a rate of 1 minute The volume of gas introduced is 2.0 reactor volumes, cooled to room temperature after heat preservation, crushed, and sieved to obtain single crystal ...

Embodiment 2

[0052] 1) Mixing: prepare high-nickel-nickel-cobalt-manganese ternary precursor powder a (the molar ratio of nickel-cobalt-manganese is 9:0.5:0.5) and b (the molar ratio of nickel-cobalt-manganese is 7.5:1:1.5), the moles of a and b Ratio 4:1, add a part weight of 2.0wt% titanium dioxide and 0.3wt% zirconia powder and lithium hydroxide powder (Li / M a =1.02) mixed in a ball mill for 12h to obtain mixed powder A; b parts were added with b parts of 1.5wt% magnesium oxide and 0.4wt% lithium fluoride powder and lithium hydroxide powder (Li / M b =1.05) mixed in a ball mill for 10h to obtain mixed powder B;

[0053] (2) Primary sintering: Put the mixed powder A obtained in step (1) into a tube furnace and heat it to 930°C at a heating rate of 6°C / min, and keep it warm for 1h, during which an oxygen atmosphere is introduced at a rate of 1 minute The volume of gas introduced is 1.0 reactor volume, cooled to room temperature after heat preservation, crushed, and sieved to obtain single ...

Embodiment 3

[0056] 1) Mixing: prepare high-nickel-nickel-cobalt-manganese ternary precursor powder a (the molar ratio of nickel-cobalt-manganese is 9.5:0.3:0.2) and b (the molar ratio of nickel-cobalt-manganese is 7:1:2), a and b moles Ratio 8:1, add a part weight of 1.0wt% titanium dioxide and 0.05wt% zirconia powder and lithium oxide powder (Li / M a =1.15) mixed in a ball mill for 8h to obtain mixed powder A; b parts were added with 1.0wt% magnesium oxide and 0.05wt% lithium fluoride powder and lithium oxide powder (Li / M b =1.18) mixed in a ball mill for 18h to obtain mixed powder B;

[0057] (2) Primary sintering: Put the mixed powder A obtained in step (1) into a tube furnace and heat it to 840°C at a heating rate of 10°C / min, and keep it warm for 8 hours, during which an oxygen atmosphere is introduced at a rate of 1 minute The volume of gas introduced is 1.5 reactor volumes, cooled to room temperature after heat preservation, crushed, and sieved to obtain single crystal powder D (D5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com