Geopolymer-based supercapacitor power storage building and preparation method thereof

A technology for supercapacitors and geopolymers, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor electrolytes, and hybrid/electric double layer capacitors. Low, energy saving, high charging and discharging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of described modified fly ash comprises:

[0045] S11, prepare modified solution, described modified solution is made of NaOH solution and NaHCO 3 Solution composition;

[0046] S12, adding the modified solution to common fly ash, stirring evenly, and standing to obtain a mixed solution;

[0047] S13, drying and roasting the mixed solution to obtain modified fly ash.

[0048] Common fly ash contains a large number of micro glass beads, the composition is silicon dioxide, and the structure is compact. The NaOH solution and NaHCO in the modified solution of the present invention 3 The solution can corrode silicon dioxide, causing the tiny glass beads in ordinary fly ash to be corroded to produce a large number of cavities, which can accelerate the transmission of conductive particles.

[0049] Specifically, the present invention consists of NaOH solution and NaHCO 3 The modified solution composed of solution can destroy part of the glassy struct...

Embodiment 1

[0106] A method for preparing a geopolymer-based supercapacitor, comprising

[0107] S1, preparing conductive paste;

[0108] Add 56 parts of ordinary fly ash to 560 parts of the modified solution, stir at room temperature for 2 hours, let it stand for 30 minutes, then put it in an oven at 80°C for drying, and then place it in a muffle furnace at 600°C for heat preservation 2h, to obtain modified fly ash; wherein, the modified solution consists of 1mol / L NaOH solution and 1mol / L NaHCO 3 Solution composition, volume of NaOH solution: NaHCO 3 The volume of the solution = 3:1;

[0109] Mix 2 parts lithium chloride and 2 parts sodium fluoride uniformly to obtain ion enhancer:

[0110] Add 3 parts of ferrosilicon powder containing 90% silicon and a fineness of 300 mesh to 28 parts of potassium silicate aqueous solution with a modulus of 2.0 and a concentration of 48%, and stir evenly to obtain a modified alkali activator;

[0111] Add the newly prepared modified base activator ...

Embodiment 2

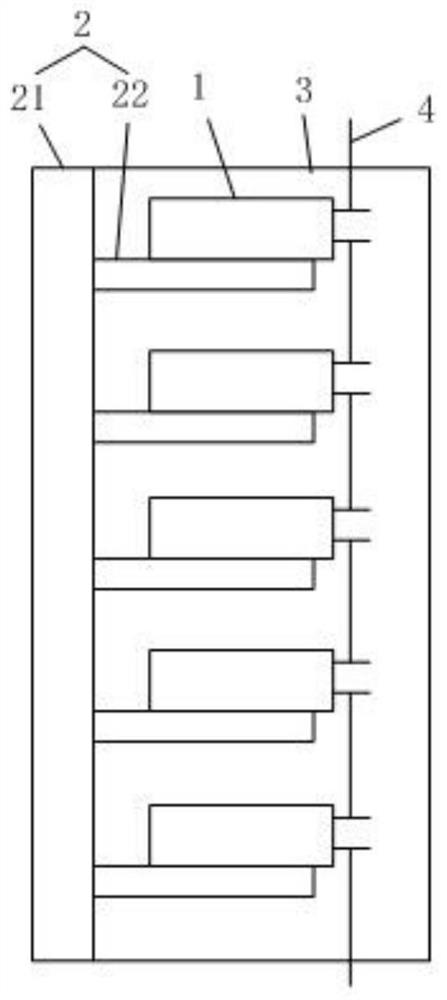

[0116] A geopolymer-based supercapacitor type concrete wall, 1.5m long, 20cm wide, and 2m high, the preparation method comprising:

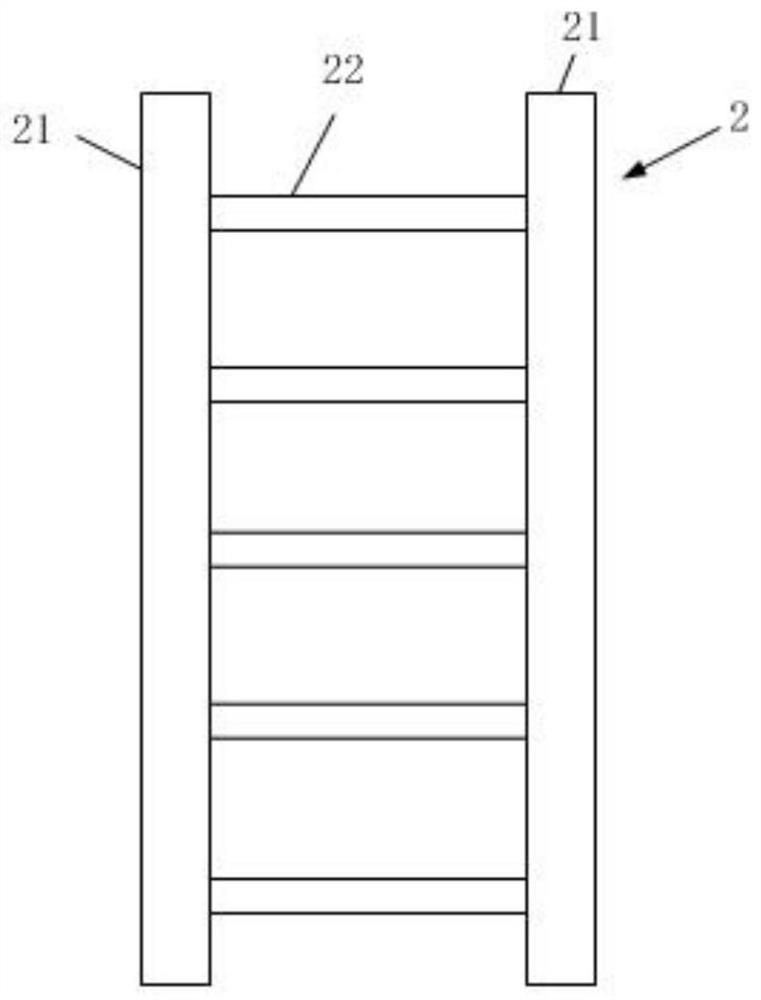

[0117] S21. Set the support and the concrete formwork in parallel to form an accommodation cavity. The concrete formwork is 1.5m long, 20cm wide, and 2m high, and the support is 2m high. There are 40 laminates for placing geopolymer-based supercapacitors, each The size of the laminate is 40mm*80mm, and the distance between the laminates is 50mm;

[0118] S22, the geopolymer-based supercapacitor of embodiment 1 is placed on the laminate of the support, and the geopolymer-based supercapacitor is formed into a wire connection with a connecting wire;

[0119] S23, pouring concrete into the accommodation cavity, and allowing the connecting wires to protrude from the concrete;

[0120] S24. After the concrete is cured according to the conventional method, the concrete formwork is removed to obtain a geopolymer-based supercapacitor-type concrete wall. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com