Rubber sealing material and preparation method thereof

A rubber seal and low-density polyethylene technology, applied in the field of materials, can solve the problems of poor mechanical properties and oil resistance stability, imports, and difficulty in meeting the use requirements of automotive seals, etc., to achieve small permanent compression deformation, good Shore hardness, good The effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

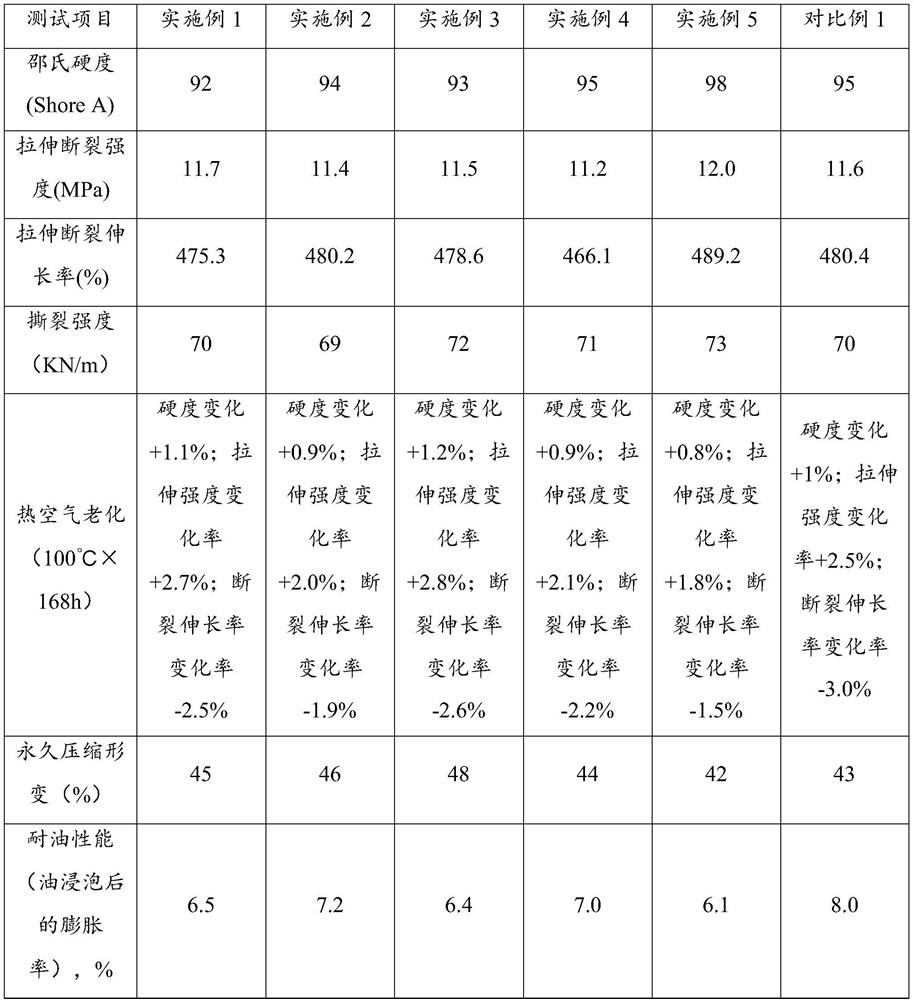

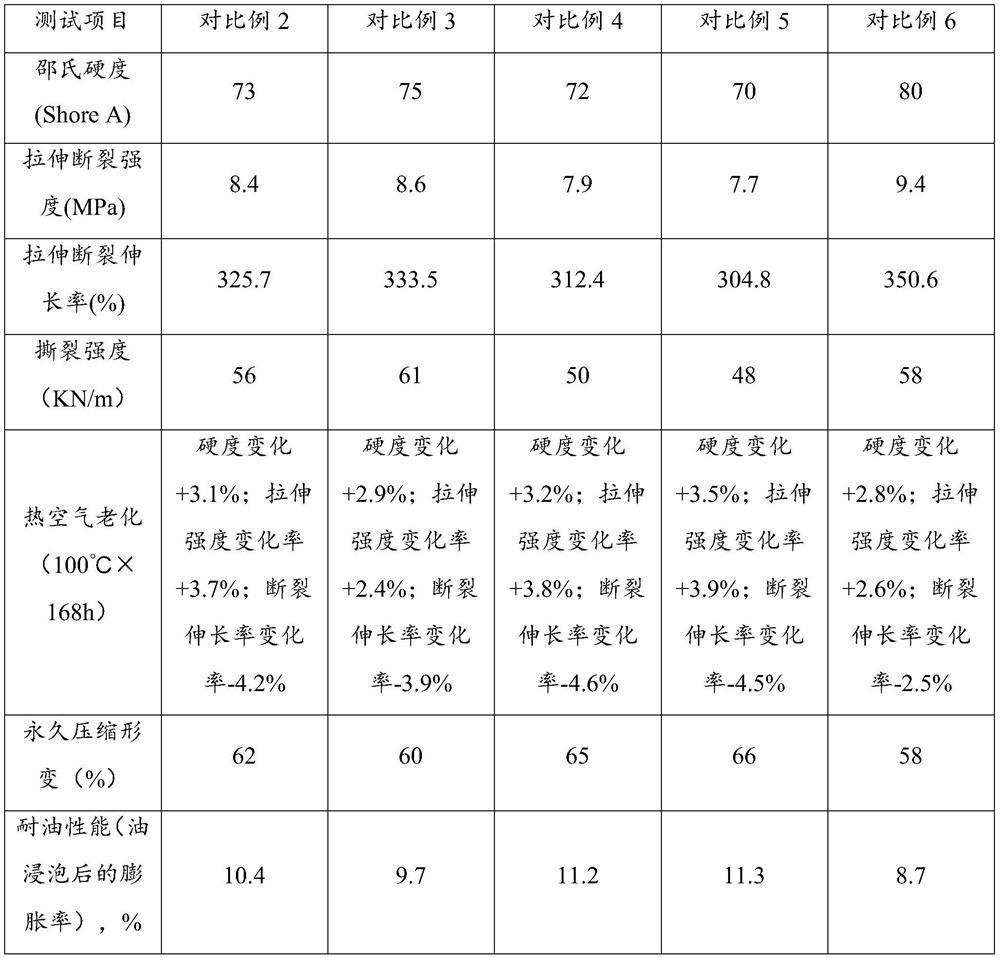

Examples

preparation example Construction

[0014] The preparation method of the rubber sealing material provided by the embodiment of the present invention uses methyl acrylate and low-density polyethylene as the base material, and is compounded with raw materials such as modified ceramic particle powder and modified sericite cloud powder, and then processed twice The rubber sealing material was prepared by vacuum mixing. The rubber sealing material has good Shore hardness, tensile breaking strength, tensile breaking elongation, tearing strength, and is resistant to hot air aging, permanent compression deformation is small, and has good oil resistance, which can meet the needs of automotive seals. usage requirements.

[0015] The embodiment of the present invention provides a method for preparing a rubber sealing material, comprising the following steps:

[0016] Step 101, weigh each component according to the following parts by weight for later use: 30-40 parts of methyl acrylate, 25-30 parts of low-density polyethyl...

Embodiment 1

[0033] The preparation steps of the rubber sealing material of the embodiment of the present invention are as follows:

[0034]Take each component by following parts by weight for subsequent use: 30 parts of methyl acrylate, 30 parts of low-density polyethylene, 10 parts of paraffin oil, 2 parts of modified ceramic particle powder, 3 parts of modified sericite cloud powder, vulcanizing agent ( Hexamethylenediamine carbamate) 0.5 part, accelerator (diphenylguanidine) 0.1 part, processing aid (potassium persulfate) 0.1 part. Methyl acrylate, low-density polyethylene, paraffin oil, modified ceramic particle powder, modified sericite cloud powder, vulcanizing agent, accelerator, processing aid are mixed and fed into a twin-screw extruder for shearing, Under the temperature condition of 75°C, vacuum kneading for 2 minutes to obtain the primary mixing material; raise the temperature of the above-mentioned primary mixing material to 85 °C, and vacuum kneading for 3 minutes to obtain ...

Embodiment 2

[0038] The preparation steps of the rubber sealing material of the embodiment of the present invention are as follows:

[0039] Take each component for subsequent use by following parts by weight: 40 parts of methyl acrylate, 25 parts of low-density polyethylene, 20 parts of paraffin oil, 8 parts of modified ceramic particle powder, 7 parts of modified sericite cloud powder, vulcanizing agent ( Hexamethylenediamine carbamate) 3 parts, accelerator (o-tolylbiguanide) 0.5 part, processing aid (ammonium persulfate) 0.2 part. Methyl acrylate, low-density polyethylene, paraffin oil, modified ceramic particle powder, modified sericite cloud powder, vulcanizing agent, accelerator, processing aid are mixed and fed into a twin-screw extruder for shearing, Under the temperature condition of 80°C, vacuum kneading for 3 minutes to obtain the primary mixing material; raise the temperature of the above-mentioned primary mixing material to 90 °C, and vacuum kneading for 3 minutes to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com