A kind of edge banding and its preparation method and application

A technology of edge banding and soft polyvinyl chloride, which is applied in the field of edge banding, can solve the problems of large thermal shrinkage rate, high collision force, and high cost, and achieve the effect of good Shore hardness, simple structure, and soft material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

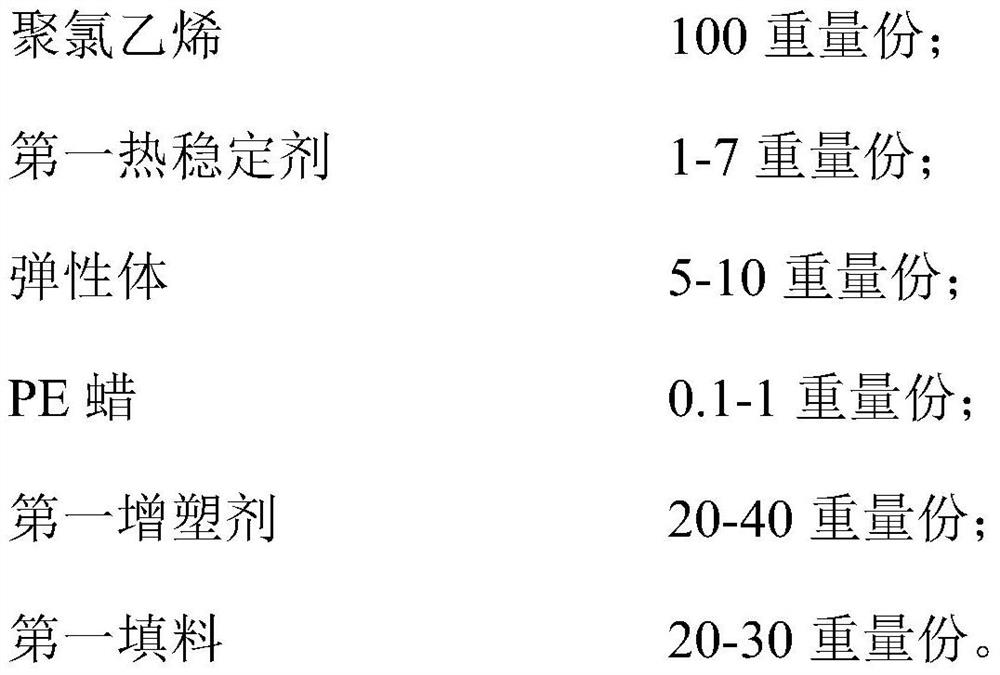

[0066] An edge strip, comprising a soft polyvinyl chloride layer and a hard polyvinyl chloride layer, wherein the preparation raw materials of the soft polyvinyl chloride layer include the following components in parts by weight:

[0067]

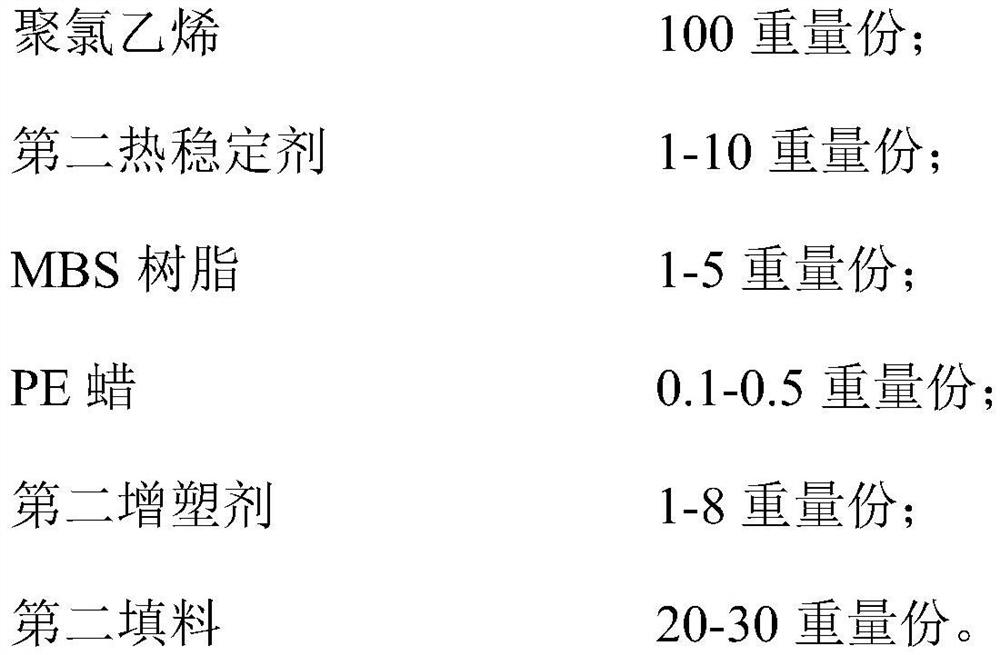

[0068] The preparation raw materials of the rigid polyvinyl chloride layer include the following components in parts by weight:

[0069]

[0070] Wherein, the elastomer is butadiene-styrene-styrene-butadiene rubber, the first plasticizer is diisononyl cyclohexane 1,2-dicarboxylate, and the first filler is double-coated modified CaCO 3 , the average particle size is 2 μm; the second filler is ultrafine calcium carbonate, and the second plasticizer is dioctyl oxalate.

[0071] The preparation method is as follows: mixing the components of the soft polyvinyl chloride and the rigid polyvinyl chloride respectively, and then co-extruding to obtain an edge band.

Embodiment 2

[0073] An edge strip, comprising a soft polyvinyl chloride layer and a hard polyvinyl chloride layer, wherein the preparation raw materials of the soft polyvinyl chloride layer include the following components in parts by weight:

[0074]

[0075] The preparation raw materials of the rigid polyvinyl chloride layer include the following components in parts by weight:

[0076]

[0077] Wherein, the elastomer is butadiene-styrene-styrene-butadiene rubber, the first plasticizer is diisononyl cyclohexane 1,2-dicarboxylate, and the first filler is double-coated modified CaCO 3 , the average particle size is 2 μm; the second filler is ultrafine calcium carbonate, and the second plasticizer is dioctyl oxalate.

[0078] Refer to Example 1 for the preparation method.

Embodiment 3

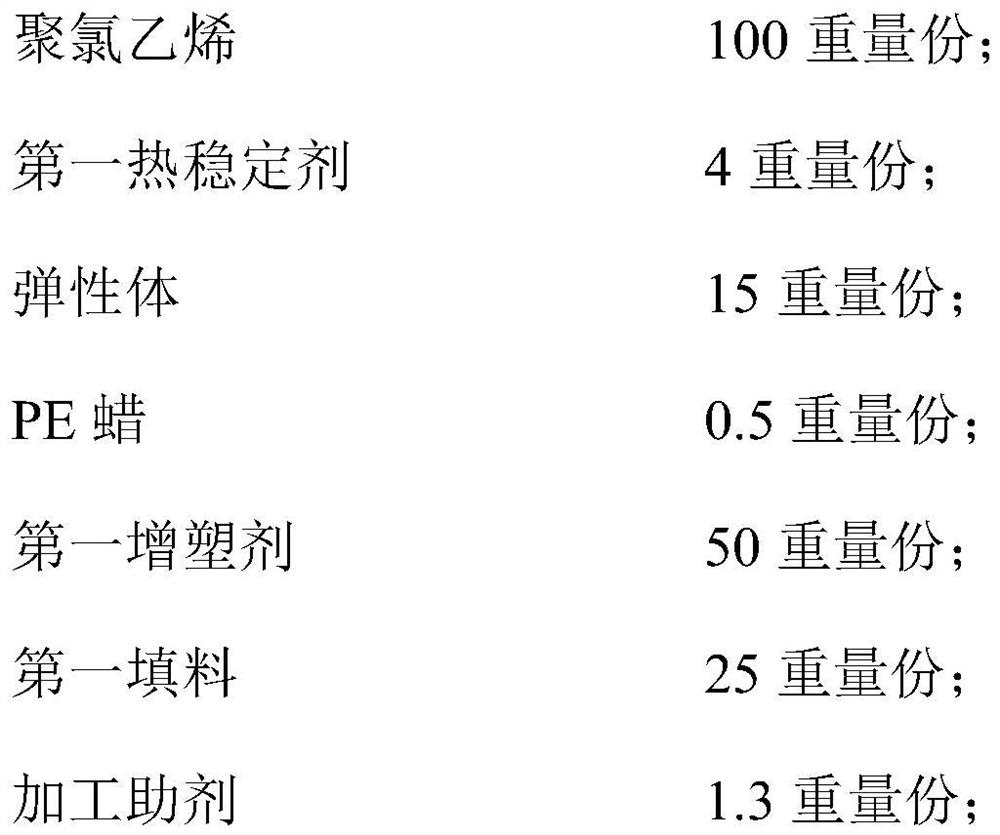

[0080] An edge strip, comprising a soft polyvinyl chloride layer and a hard polyvinyl chloride layer, wherein the preparation raw materials of the soft polyvinyl chloride layer include the following components in parts by weight:

[0081]

[0082] The preparation raw materials of the rigid polyvinyl chloride layer include the following components in parts by weight:

[0083]

[0084] Wherein, the elastomer is butadiene-styrene-styrene-butadiene rubber, the first plasticizer is diisononyl cyclohexane 1,2-dicarboxylate, and the first filler is double-coated modified CaCO 3 , the average particle size is 3 μm; the second filler is ultrafine calcium carbonate, and the second plasticizer is dioctyl oxalate.

[0085] Refer to Example 1 for the preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com