Conveying device

A conveying device and conveying mechanism technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as negative impacts on the next process, mechanical accidents, etc., to improve production efficiency, not easily damaged, and reduce impact force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

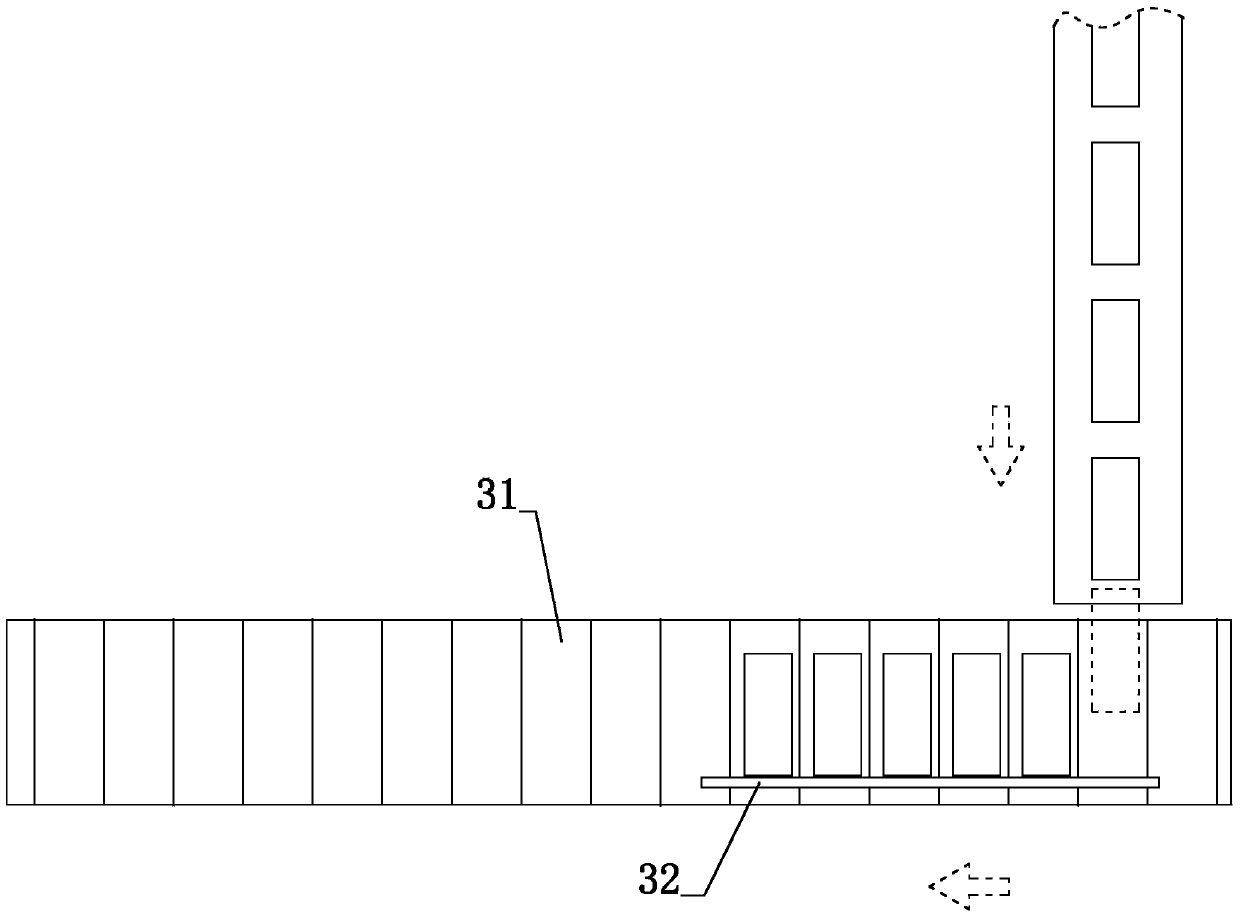

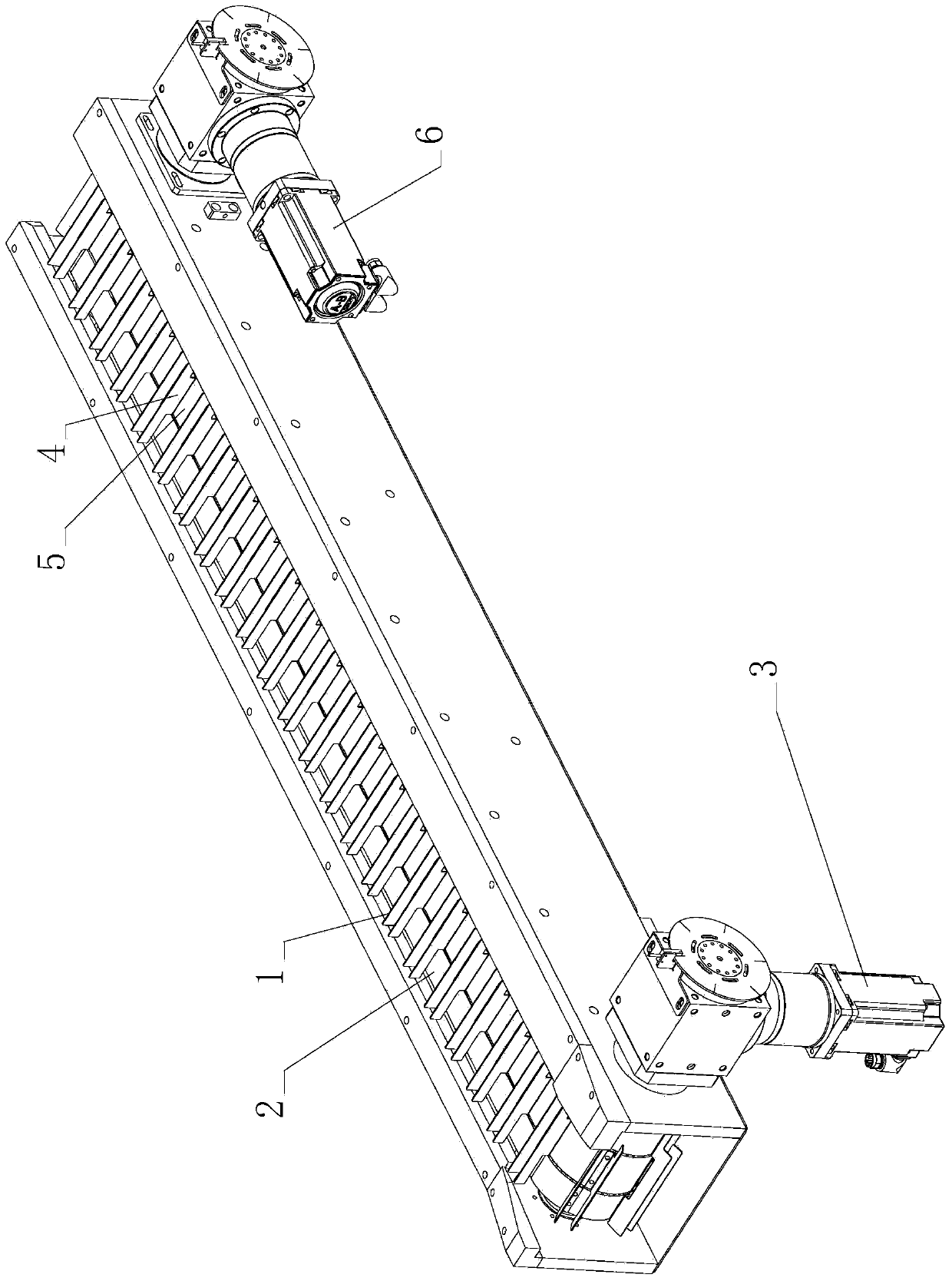

[0028] Such as figure 2 , 3 As shown, the circular arrangement mechanism includes a first conveying mechanism, a second conveying mechanism and a frame.

[0029] The first conveying mechanism comprises the first baffle plate 1, two first driving pulleys, two first driven pulleys, two first synchronous belts 2 and a first servo motor 3; the second conveying mechanism comprises the second Baffle plate 4, a second driving pulley, a second driven pulley, a second synchronous belt 5 and a second servo motor 6. Two parallel rotating shafts are installed on the frame, including a first rotating shaft and a second rotating shaft, and the rotating shafts are all movably installed on the frame through bearings.

[0030] The first driving pulley is fixedly installed on the first rotating shaft, the first rotating shaft is provided with a keyway, the first driving pulley is also provided with a keyway, and the first driving pulley and the first rotating shaft are fixed by inserting a k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com