Zinc dialkyl dithiophosphate and preparation method thereof

A technology of zinc dialkyldithiophosphate and sulfuric acid, which is applied in the field of rubber vulcanization accelerators, can solve the problems of increasing the application of catalyst ammonia water, poor anti-aging and yellowing resistance, and severe local reactions, and meet the production process conditions Ease of control, good yellowing resistance, excellent rubber properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

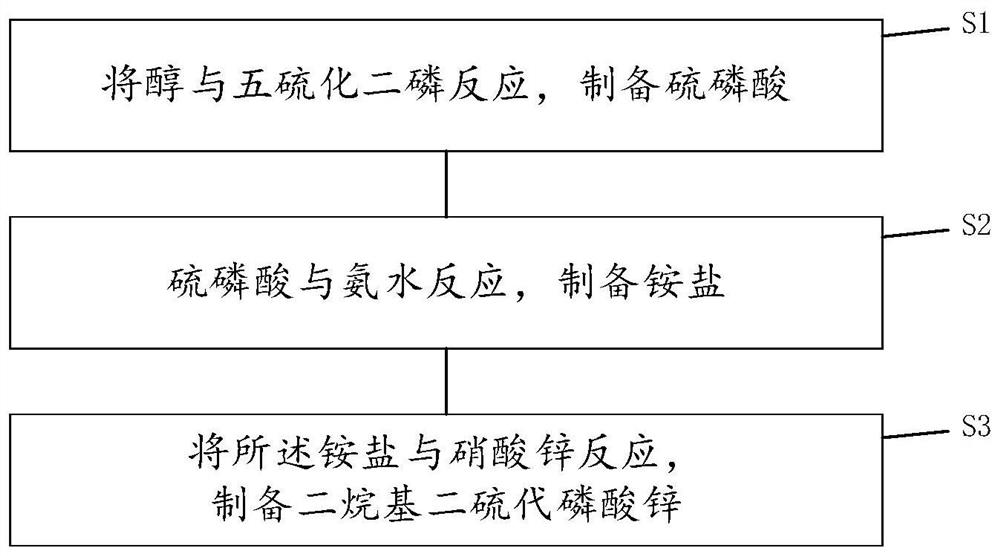

[0025] A kind of preparation method of zinc dialkyl dithiophosphate, such as figure 1 Shown, described preparation method comprises:

[0026] Step S1: react alcohol with phosphorus pentasulfide to prepare sulfuric acid. Wherein, alcohol can be a kind of alcohol, also can be the mixture of two kinds of alcohols, for example n-butanol and isooctyl alcohol, or their mixture.

[0027] Step S2: react phosphoric acid with ammonia water to prepare ammonium salt.

[0028] Step S3: reacting the ammonium salt with zinc nitrate to prepare zinc dialkyldithiophosphate.

[0029] Step S4: Separating the reaction product of step S3 and washing it with distilled water; removing water under reduced pressure; adding a filter aid and filtering to obtain a finished product of zinc dialkyldithiophosphate.

[0030] Among them, ammonia water participates in the reaction, and the final product is ammonium nitrate, which is convenient for the treatment of later products; the reaction will not cause ...

Embodiment 1

[0046] Add 14.7g (10% of the total amount) n-butanol and isooctyl alcohol (mix well) in the four-necked flask, and connect the tail gas treatment device, and the phosphorus pentasulfide of 80.0g (the P content of the selected phosphorus pentasulfide is 28.1-28.2 %) into the flask, after heating up to 70°C, start to drop the remaining 132.3g of mixed alcohol to ensure that the temperature of the reaction system does not exceed 75°C, after the addition, raise the temperature of the system to 95°C and keep it for about 2.0h, and cool down after the reaction To below 20 ° C, sulfuric acid is obtained.

[0047] Add 25.0 g of ammonia water into the reaction system dropwise in 6 times at intervals of 15 minutes to ensure that the reaction system does not exceed 35° C. After the addition, keep warm for 1.0 h to obtain the ammonium salt.

[0048] Will prepare 120.0g Zn(NO3) 2 (a solution with a mass fraction of 40%) was added to a constant pressure dropping funnel, and evenly added dr...

Embodiment 2

[0050] It is 27.9-28.1% that the phosphorus pentasulfide in the embodiment 1 is changed into the phosphorus pentasulfide of P content, all the other parts are kept the same with embodiment 1, make light yellow transparent finished product, be recorded as: product 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com