Plant-based material as well as preparation method and application thereof

A plant-based, material technology, applied in the field of plastic processing, can solve the problems of poor dispersion of coffee grounds, destruction of PLA materials, poor compatibility between coffee grounds and PLA resin, etc., to achieve short degradation time, reduce damage, and achieve high green circulation. The effect of value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

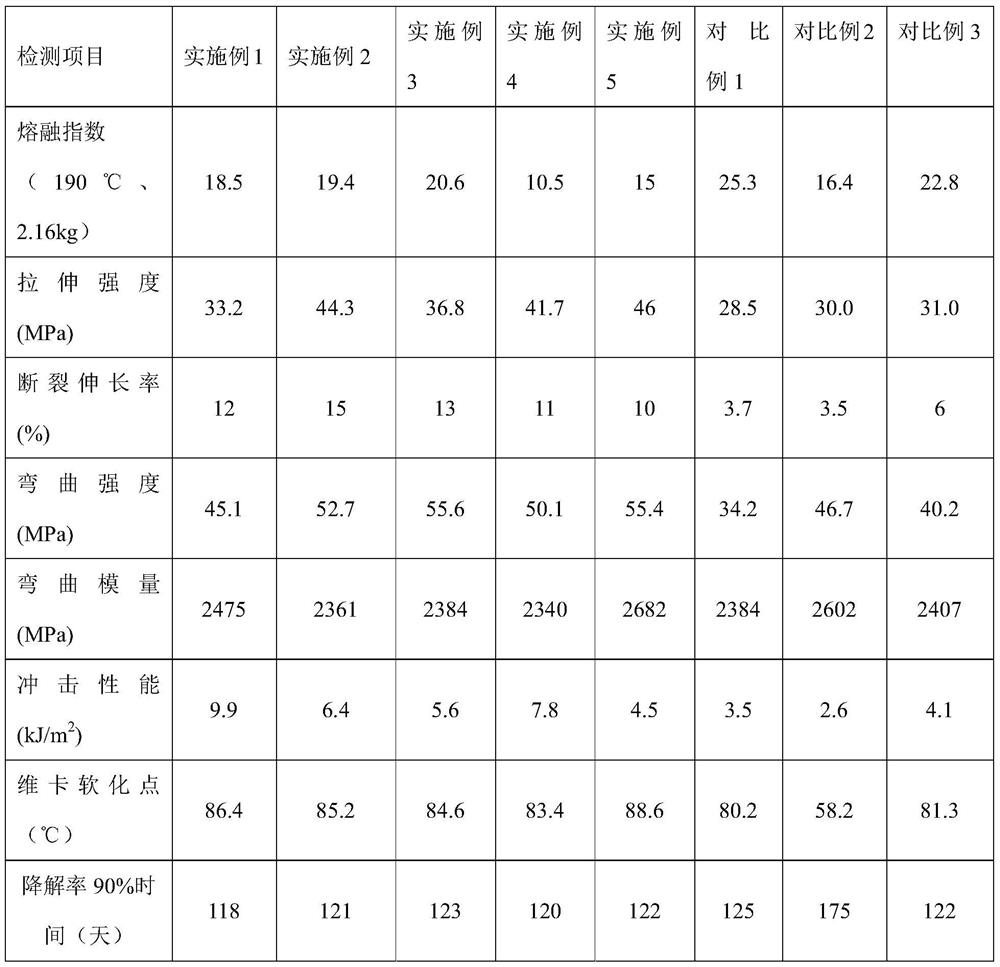

Examples

Embodiment 1

[0067] Embodiment 1 Plant-based material and preparation method thereof

[0068] Plant-based material formula: 67.2% polylactic acid resin, 10% PBAT, 20% coffee grounds, 0.5% nucleating agent, 2% plasticizer, 0.3% antioxidant; the above percentages are mass percentages; the nucleating agent is talc powder, the plasticizer is acetyl tributyl citrate, and the antioxidant is antioxidant 168.

[0069] Plant-based material preparation method:

[0070] 1. Dry the polylactic acid resin, toughening resin (PBAT), and coffee grounds, and grind the coffee grounds to a particle size of 40 mesh.

[0071] 2. Weigh polylactic acid resin, PBAT, and additives (ie, nucleating agent, plasticizer, antioxidant) in proportion to the mixer and mix evenly, then add coffee grounds and mix evenly, and then use the eccentric rotor The stretching rheological plasticizing extrusion equipment is used for melt extrusion granulation. This embodiment adopts the eccentric rotor volume pulsating deformation p...

Embodiment 2

[0072] Embodiment 2 Plant-based material and preparation method thereof

[0073] Plant-based material formula: 67.2% polylactic acid resin, 10% PBS, 20% coffee grounds, 0.5% nucleating agent, 2% plasticizer, 0.3% antioxidant; the above percentages are mass percentages; the nucleating agent is Mongolian Desoiling, plasticizer is epoxy soybean oil, antioxidant is antioxidant 1010.

[0074] Plant-based material preparation method:

[0075] 1. Dry the polylactic acid resin, toughening resin (PBS), and coffee grounds, and grind the coffee grounds to a particle size of 60 mesh.

[0076] 2. Then weigh polylactic acid resin, PBS, and additives (ie, nucleating agent, plasticizer, antioxidant) in proportion and add them to the mixer to mix evenly, then add coffee grounds and mix evenly, and then use stretching The rheological plasticizing extrusion equipment is used for melt extrusion granulation. This embodiment adopts the eccentric rotor volume pulsating deformation plasticizing tra...

Embodiment 3

[0077] Embodiment 3 Plant-based material and preparation method thereof

[0078] Plant-based material formula: 72.2% polylactic acid resin, 10% PBAT, 15% coffee grounds, 0.5% nucleating agent, 2% plasticizer, 0.3% antioxidant; the above percentages are mass percentages; the nucleating agent is two Silica, the plasticizer is acetyl tributyl citrate, and the antioxidant is 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane.

[0079] Plant-based material preparation method:

[0080] 1. Dry the polylactic acid resin, toughening resin (PBAT), and coffee grounds, and grind the coffee grounds to a particle size of 150 mesh;

[0081] 2. Then weigh polylactic acid resin, PBAT, and additives (ie, nucleating agent, plasticizer, antioxidant) in proportion and add them to the mixer to mix evenly. After adding coffee grounds, mix evenly, and then use stretching flow Variable plasticizing extrusion equipment for melt extrusion granulation, this embodiment uses the eccentric rotor volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com