Breathable degradable dressing and preparation method thereof

A technology of hyaluronic acid and parts by mass, applied in the field of medical materials, can solve the problems of poor air permeability, unfavorable water vapor evaporation, troublesome use, etc., and achieve the effects of short degradation time, good market prospects, and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

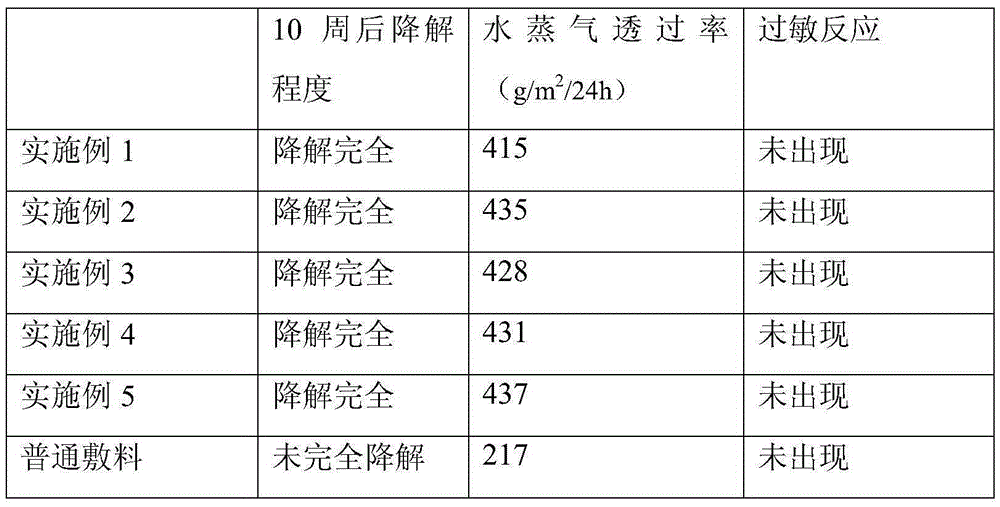

Examples

Embodiment 1

[0016] A breathable and degradable dressing, consisting of the following components by mass: 34 parts of sodium carboxymethylcellulose, 17 parts of hyaluronic acid, 5 parts of calcium alginate, 1 part of β-cyclodextrin, and tributyl citrate 2 parts of ester, 9 parts of polyvinyl alcohol, 3 parts of ethylenediaminetetraacetic acid, 2 parts of nano-zinc oxide, and 1 part of boric acid.

[0017] Preparation:

[0018] (1) Mix sodium carboxymethylcellulose, hyaluronic acid, β-cyclodextrin, nano-zinc oxide, polyvinyl alcohol and calcium alginate according to the above parts by mass, and obtain mixture 1 after ultrasonication for 5 minutes;

[0019] (2) Add tributyl citrate, ethylenediaminetetraacetic acid and boric acid to mixture 1, place in a mixer, and stir evenly at a temperature of 60° C. to obtain mixture 2, wherein the pressure of the mixer is 1.4 MPa;

[0020] (3) Soak the degreasing gauze in the mixture 2, place it in a dryer, dry it at 70° C., seal it, pack it, and steril...

Embodiment 2

[0022] A breathable and degradable dressing, consisting of the following components by mass: 58 parts of sodium carboxymethylcellulose, 31 parts of hyaluronic acid, 19 parts of calcium alginate, 10.5 parts of β-cyclodextrin, and tributyl citrate 9 parts of ester, 20 parts of polyvinyl alcohol, 11 parts of ethylenediaminetetraacetic acid, 12 parts of nano-zinc oxide, and 8 parts of boric acid.

[0023] Preparation:

[0024] (1) Mix sodium carboxymethylcellulose, hyaluronic acid, β-cyclodextrin, nano-zinc oxide, polyvinyl alcohol and calcium alginate according to the above parts by mass, and obtain mixture 1 after ultrasonication for 15 minutes;

[0025] (2) Add tributyl citrate, ethylenediaminetetraacetic acid and boric acid to mixture 1, place in a blender, and stir evenly at a temperature of 110° C. to obtain mixture 2, wherein the pressure of the blender is 2.7 MPa;

[0026] (3) Soak the degreased gauze in the mixture 2, place it in a dryer, dry it at 90° C., seal it, pack ...

Embodiment 3

[0028] A breathable and degradable dressing, consisting of the following components by mass: 36 parts of sodium carboxymethylcellulose, 19 parts of hyaluronic acid, 6 parts of calcium alginate, 2 parts of β-cyclodextrin, tributyl citrate 3 parts of ester, 11 parts of polyvinyl alcohol, 5 parts of ethylenediaminetetraacetic acid, 4 parts of nano-zinc oxide, and 2 parts of boric acid.

[0029] Preparation:

[0030] (1) Mix carboxymethylcellulose sodium, hyaluronic acid, β-cyclodextrin, nano-zinc oxide, polyvinyl alcohol and calcium alginate according to the above mass parts, and obtain mixture 1 after ultrasonication for 6 minutes;

[0031] (2) Add tributyl citrate, ethylenediaminetetraacetic acid and boric acid to mixture 1, place in a blender, and stir evenly at a temperature of 70° C. to obtain mixture 2, wherein the pressure of the blender is 1.8 MPa;

[0032] (3) Soak the degreasing gauze in the mixture 2, place it in a dryer, dry it at 75° C., seal it, pack it, and steril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com