Preparation method of nano titanium dioxide with photocatalytic performance

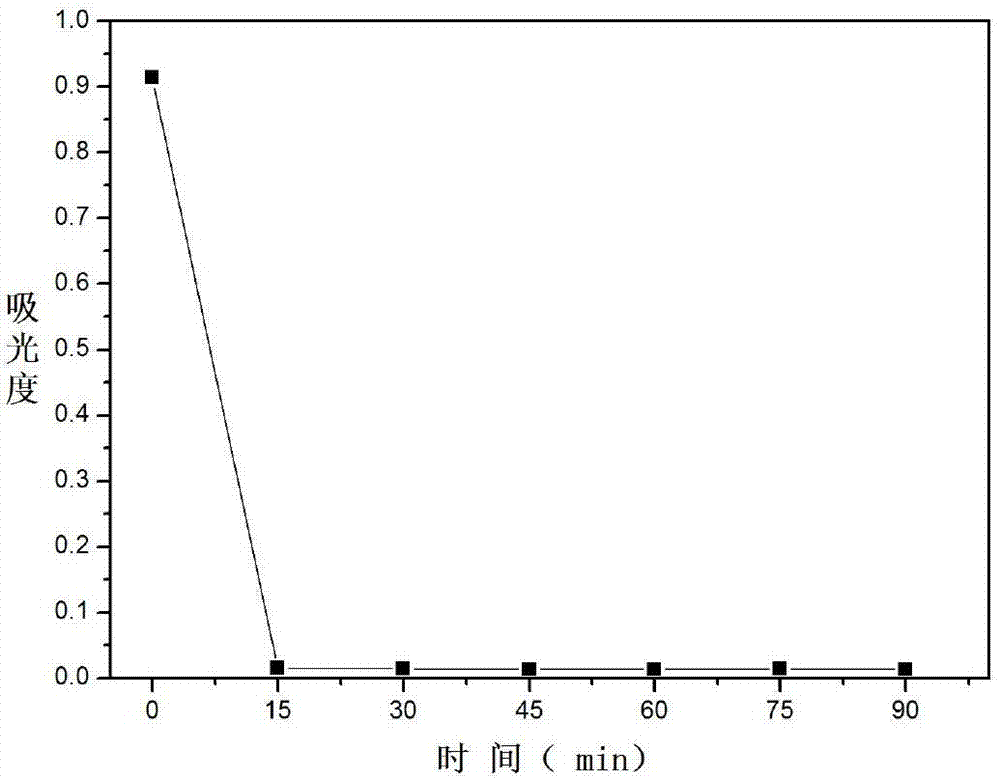

A nano-titanium dioxide, photocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low degradation rate, long photodegradation period, poor photocatalytic performance of titanium dioxide, etc. The effect of high degradation rate and short degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

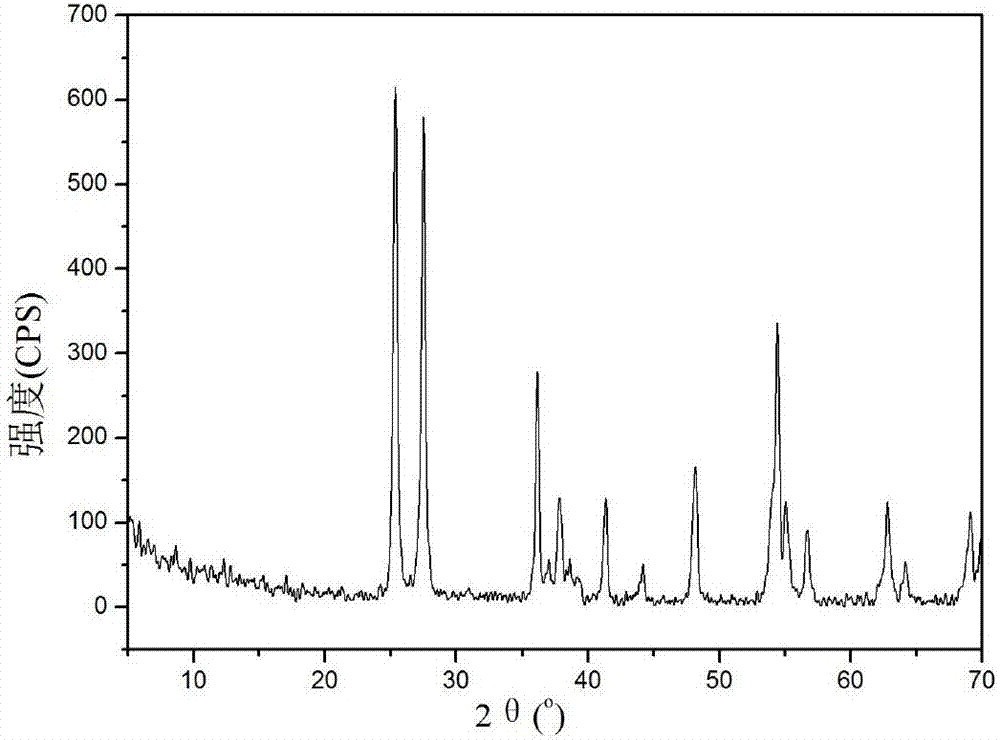

[0014] Nanoscale titanium dioxide was prepared using ramie fiber carboxymethyl cellulose as a template.

[0015] (1), activation treatment of ramie fiber carboxymethyl cellulose:

[0016] Add 0.5g of ramie fiber carboxymethyl cellulose to 10mL of 10% sodium hydroxide solution by mass percentage, then add 0.5mL of dimethyl sulfoxide, stir at room temperature for 10h or ultrasonically react at room temperature for 0.5h, after the reaction Add 3.3g of sodium chloroacetate and 0.5g of catalyst 4-dimethylaminopyridine to the final solution, then ultrasonically react for 2 hours at 40°C in 20% sodium hydroxide solution, and then use sulfuric acid to lower the pH of the solution after the reaction is stopped. The value was adjusted to 2, and finally the activated ramie fiber carboxymethyl cellulose was obtained by suction filtration washing with absolute ethanol and distilled water and drying in air at 60°C for 5 hours.

[0017] (2), water treatment:

[0018] Weigh 0.5 g of activat...

Embodiment 2

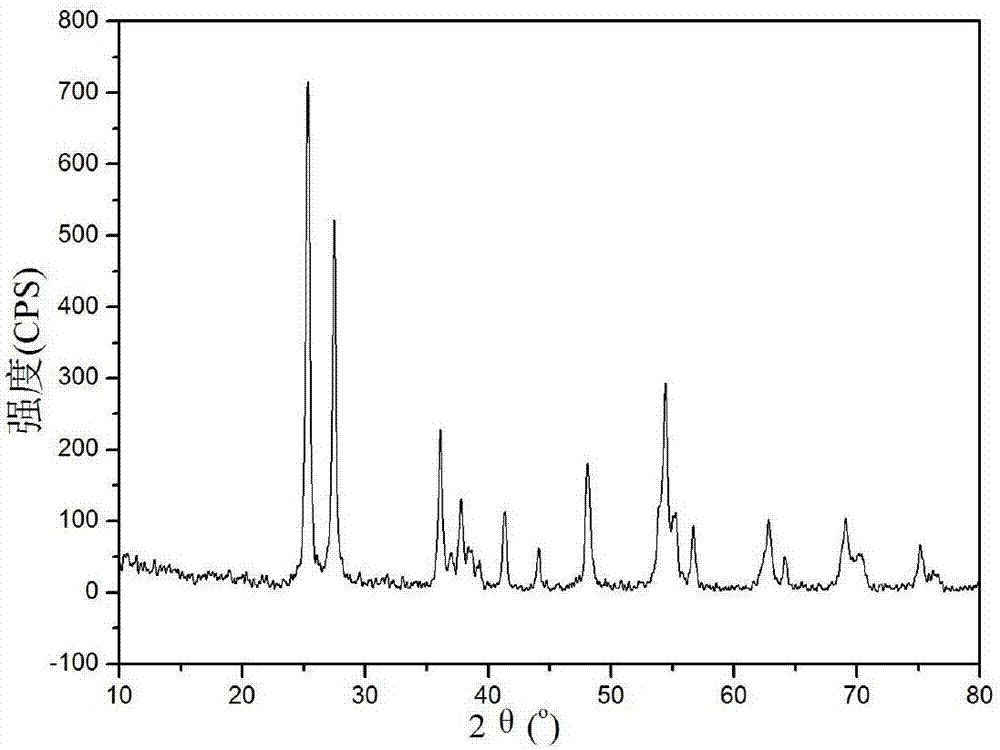

[0024] Nano-titanium dioxide was prepared using ramie fiber as a template.

[0025] (1), activation treatment of ramie fiber:

[0026] Add 0.5g ramie fiber to 10mL of 30% sodium hydroxide solution by mass percentage, then add 1mL dimethyl sulfoxide, stir at room temperature for 20h or ultrasonically react at room temperature for 2h, add 3.3g Sodium chloroacetate and 0.5g catalyst 4-dimethylaminopyridine, then ultrasonically reacted in 20% sodium hydroxide solution at 80°C for 2h, after stopping the reaction, adjust the pH value of the solution to 3 with sulfuric acid, and finally use Activated ramie fibers were prepared by suction filtration, washing with absolute ethanol and distilled water, and drying in air at 60°C for 5 hours.

[0027] (2), water treatment:

[0028] Weigh 0.5 g of activated ramie fibers in step (1) and carry out water treatment at room temperature, so that the ramie fibers contain 15% water by mass.

[0029] (3), get the 0.5g ramie fiber that the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com