Preparation method and application of high-purity lithium sulfide

A lithium sulfide, high-purity technology, applied in chemical instruments and methods, inorganic chemistry, lithium compounds, etc., can solve problems such as large interface interaction, low product purity, and difficult purification, and achieve enhanced electronic conductivity and high electronic conductivity , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

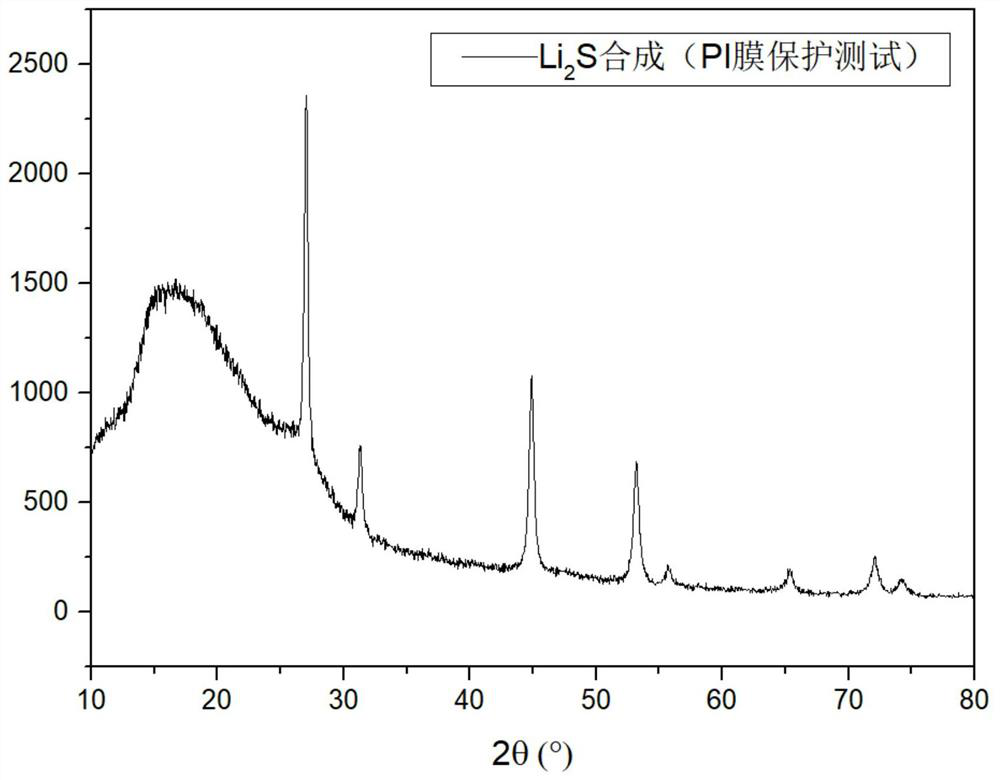

Image

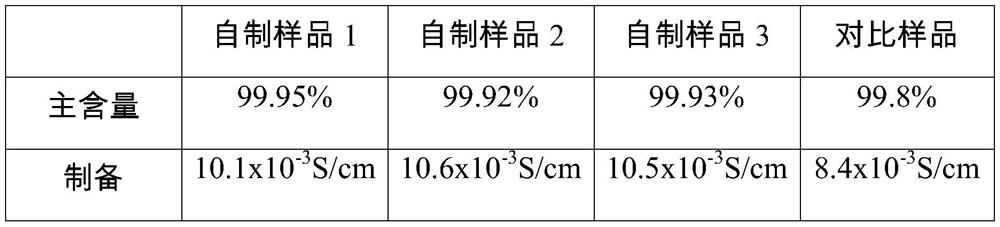

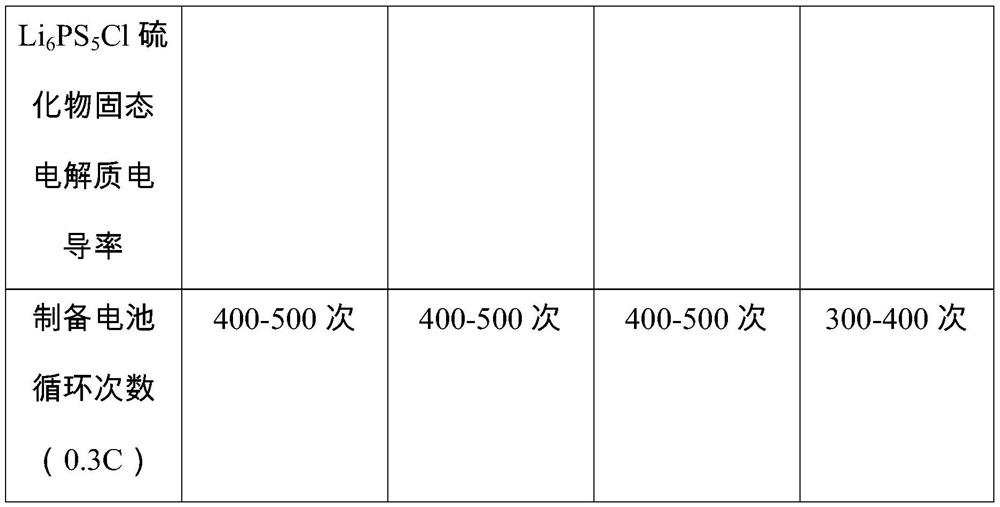

Examples

preparation example Construction

[0012] The invention provides a kind of preparation method of high-purity lithium sulfide, and this preparation method comprises the following steps:

[0013] Step 1: ball milling the defective lithium amide until the D50 remains below 50 microns to obtain lithium amide particle powder;

[0014] Step 2: Put the lithium amide particle powder in a reaction furnace with a stirring device, evacuate the reaction furnace to a vacuum degree of -0.1mpa, raise the temperature of the reaction furnace to 200-300°C, and then feed hydrogen sulfide into the reaction furnace Gas, keep the pressure of the reaction furnace at 0.1-0.15mpa, stir and react for 3-5 hours;

[0015] Step 3: Turn off the hydrogen sulfide gas, raise the temperature of the reaction furnace to 400-430°C, keep it warm for 0.5-1 hour, and vacuumize the reaction furnace to a vacuum degree of -0.1mpa after the heat preservation is completed;

[0016] Step 4: Introduce hydrogen sulfide gas again, keep the pressure of the re...

Embodiment 1

[0024] Step 1: ball milling the defective lithium amide until the D50 remains below 50 microns to obtain lithium amide particle powder;

[0025] Step 2: Put the lithium amide particle powder in a reaction furnace with a stirring device, evacuate the reaction furnace to a vacuum degree of -0.1mpa, raise the temperature of the reaction furnace to 200°C, and then pass hydrogen sulfide gas into the reaction furnace, Keep the reaction furnace pressure at 0.1mpa, stir and react for 5 hours;

[0026] Step 3: Turn off the hydrogen sulfide gas, raise the temperature of the reaction furnace to 430°C, and keep it warm for 0.5 hours. After the heat preservation is completed, evacuate the reaction furnace to a vacuum degree of -0.1mpa;

[0027] Step 4: Introduce hydrogen sulfide gas again to keep the pressure of the reactor at 0.1mpa, and raise the temperature to 430°C for 3 hours;

[0028] Step 5: The reacted lithium sulfide is ball milled and sieved, and the D50 is controlled to be 10-5...

Embodiment 2

[0030] Step 1: ball milling the defective lithium amide until the D50 remains below 50 microns to obtain lithium amide particle powder;

[0031] Step 2: Put the lithium amide particle powder in a reaction furnace with a stirring device, evacuate the reaction furnace to a vacuum degree of -0.1mpa, raise the temperature of the reaction furnace to 250°C, and then pass hydrogen sulfide gas into the reaction furnace, Keep the reaction furnace pressure at 0.13mpa, stir and react for 4 hours;

[0032] Step 3: Turn off the hydrogen sulfide gas, raise the temperature of the reaction furnace to 420°C, and keep it warm for 0.75 hours. After the heat preservation is completed, vacuum the reaction furnace to a vacuum degree of -0.1mpa;

[0033] Step 4: Introduce hydrogen sulfide gas again to keep the pressure of the reactor at 0.75mpa, and raise the temperature to 430°C for 4 hours;

[0034] Step 5: The reacted lithium sulfide is ball milled and sieved, and the D50 is controlled to be 10-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com