End trimming machine for stainless steel hollow pipe machining

A stainless steel, empty tube technology, used in metal processing machinery parts, machine tools suitable for grinding workpiece edges, metal processing equipment, etc., can solve problems such as cumbersome, cutting end damage, and incapable cutting end grinding, saving driving costs. , to avoid shaking, to avoid the effect of hard touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

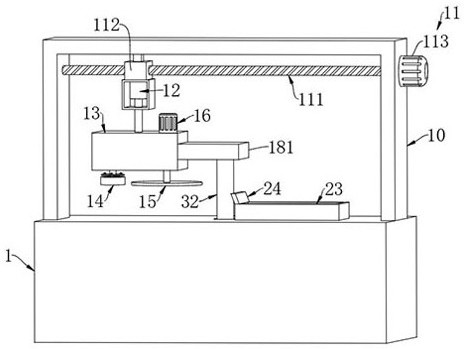

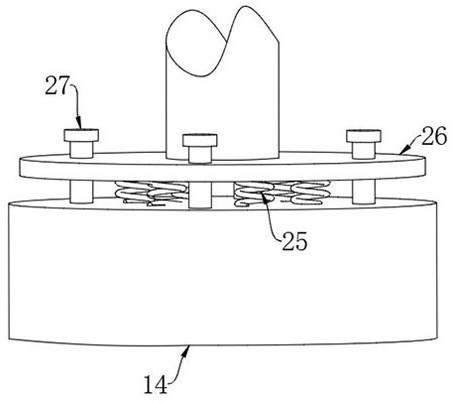

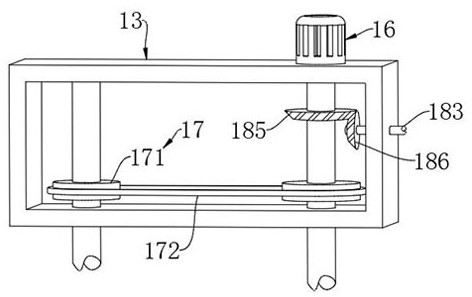

[0032] Such as Figure 1-6 As shown, an end trimming machine for stainless steel hollow pipe processing includes a hollow workbench 1, a partition 2 is fixedly connected to the hollow workbench 1, and an opening slot 3 is provided on the upper end of the hollow workbench 1, and on the partition 2 A counter slot 4 corresponding to the opening slot 3 is provided, and a filter screen 5 is embedded on the inner top surface of the lower end of the counter slot 4, and a rotating shaft 6 is rotatably connected to the hollow workbench 1, and the rotating shaft 6 runs through the counter slot 4 and the opening in turn. The slot 3 is set, and the receiving box 22 is sleeved on the rotating shaft 6, and the receiving box 22 is a frustum-shaped design as a whole. The upper end of the hollow workbench 1 is fixedly connected with a receiving box 23, and one side of the receiving box 23 is fixedly connected with a guide The plate 24 and the receiving box 22 are convenient to accept the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com