Automatic plate shearing machine for sheet metal machining

A shearing machine and sheet metal technology, which is applied in the field of automatic shearing machines for sheet metal processing, can solve the problems of operator's hand cuts and low efficiency, and achieve the effects of reducing labor costs, eliminating handling operations, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

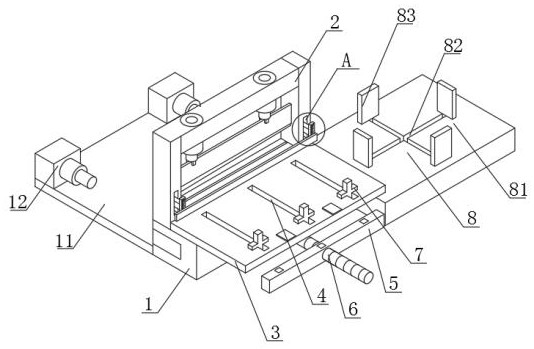

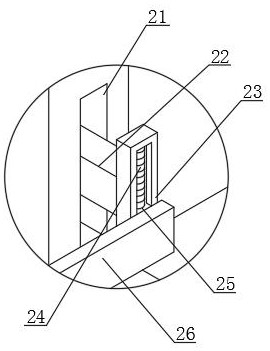

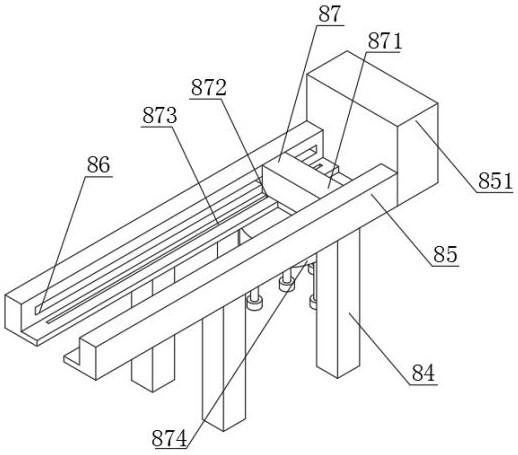

[0030] Refer to the attached Figure 1-4 , an automatic shearing machine for sheet metal processing, including a workbench 1, a hydraulic shearing device 2 is arranged on the top of the workbench 1, and a pusher plate 3 is connected to the bottom side of the hydraulic shearing device 2, and the pusher plate 3 is provided with a plurality of sliding grooves 4, the bottom of the sliding groove 4 is provided with a transverse sliding plate 5, and the middle of the transverse sliding plate 5 is provided with a threaded hole, the threaded hole is connected to the sliding screw 6, the sliding The end of the screw 6 is connected to the drive motor, the top of the lateral sliding plate 5 is connected to the cross push plate 7 at the position corresponding to the sliding groove 4, the side of the automatic push plate 3 is provided with a plate feeding part 8, the device works When the metal plate is placed on the plate feeding part 8, the plate feeding part 8 sends the metal plate to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com