Magnesium oxide-metal sulfide-biomass charcoal composite material as well as preparation method and application thereof

A technology of metal sulfide and biochar, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., to achieve low thermal expansion coefficient, rich pore structure, and excellent adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

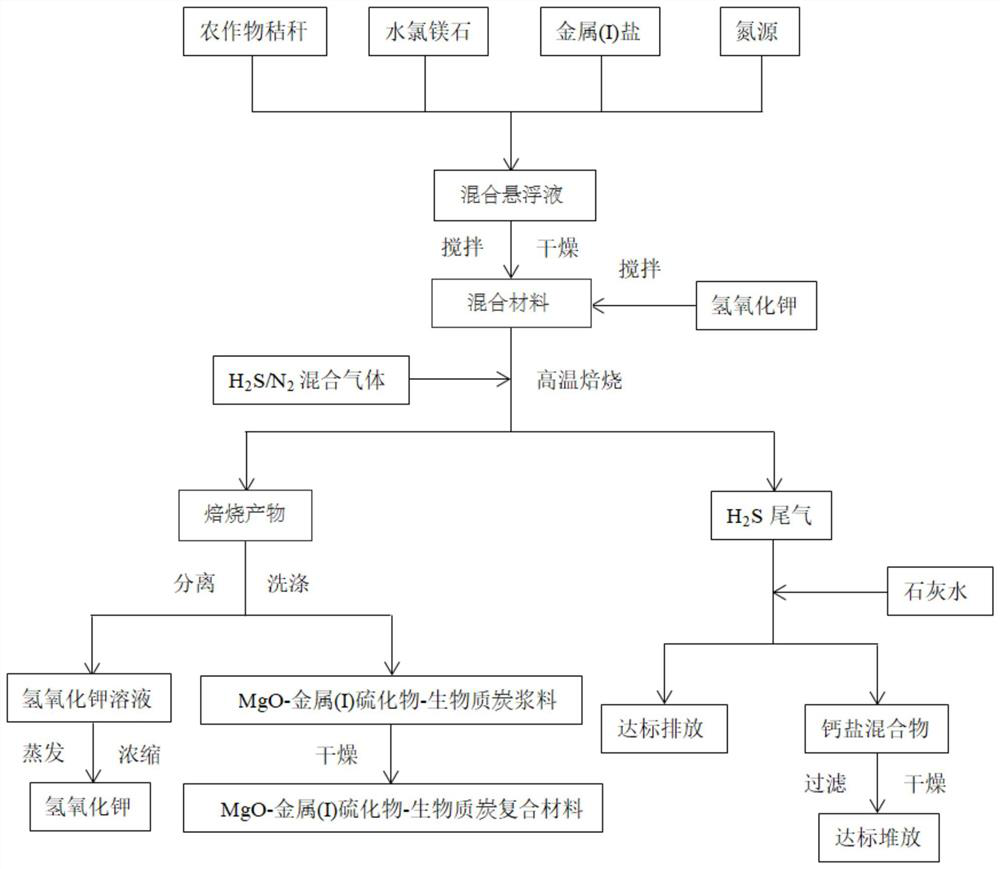

[0039] The embodiment of the present invention also provides a preparation method of magnesium oxide-metal sulfide-biomass charcoal composite material as described above, refer to figure 1 , the preparation method comprises:

[0040] Step S10, dissolving the biomass waste, bischofolite, monovalent metal salt and nitrogen source organic matter in a solvent, stirring and mixing, heating to evaporate the solvent, and obtaining a mixed material.

[0041] Preferably, the biomass waste is crop straw, the main component of the crop straw is biomass carbon, which needs to be pulverized first; the bischofolite is a by-product of the potassium extraction process, and the main component is magnesium chloride hexahydrate ; The monovalent metal salt is silver nitrate, silver chloride, silver sulfate, cuprous chloride or cuprous sulfate; the nitrogen source organic matter is melamine, urea or polyvinylpyrrolidone.

[0042] Further preferably, in terms of parts by mass, the mass fraction of...

Embodiment 1

[0065] Step 1, take by weighing 75g of pulverized rice straw, 15g of potassium extract by-product bischolite, 2g of silver nitrate and 8g of melamine are placed in a batching tank filled with 600mL of deionized water, and at room temperature with a rotating speed of 300 r / Min was stirred for 0.5h. The temperature of the mixed suspension in the batching tank was raised to 60° C. and stirred at a constant temperature until the deionized water was completely evaporated to obtain a mixed material.

[0066] Step 2: Add 20g of potassium hydroxide to the mixed material, stir evenly and put it into a high-temperature converter with a rotation speed of 10 r / min, and feed H 2 H with a volume fraction of S of 25% and a gas flow rate of 80 mL / min 2 S / N 2 The air in the furnace was exhausted with the mixed gas, and the temperature was raised to 600°C at a rate of 10°C / min under the atmosphere and roasted at a constant temperature for 3 hours to obtain a roasted product.

[0067] The wa...

Embodiment 2

[0072] Step 1. Weigh 70g of pulverized wheat straw, 13g of potassium-extracting by-product bischolite, 2g of cuprous chloride and 15g of urea into a batching tank filled with 550mL of deionized water, and at room temperature at a speed of Stir at 250 r / min for 0.5h. The temperature of the mixed suspension in the batching tank was raised to 65° C. and stirred at a constant temperature until the deionized water was completely evaporated to obtain a mixed material.

[0073] Step 2: Add 15g of potassium hydroxide to the mixed material, stir evenly and put it into a high-temperature converter with a rotation speed of 10 r / min, and feed H 2 H with a volume fraction of S of 30% and a gas flow rate of 70 mL / min 2 S / N 2 The mixed gas exhausted the air in the furnace, and in this atmosphere, the temperature was raised to 650°C at 15°C / min and roasted at a constant temperature for 2.5h to obtain a roasted product.

[0074] The waste gas generated during the reaction process is absorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com