Decorative material for floor

A technology for decorative materials and floors, applied in the directions of floor covering, application, household appliances, etc., can solve the problem of cold floor mats, etc., and achieve the effects of excellent shape stability, excellent surface characteristics, and excellent construction ease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

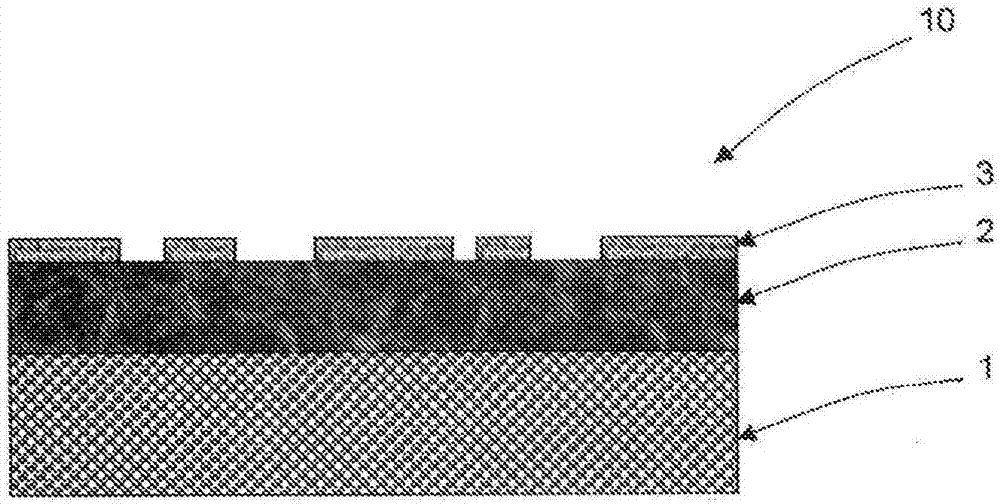

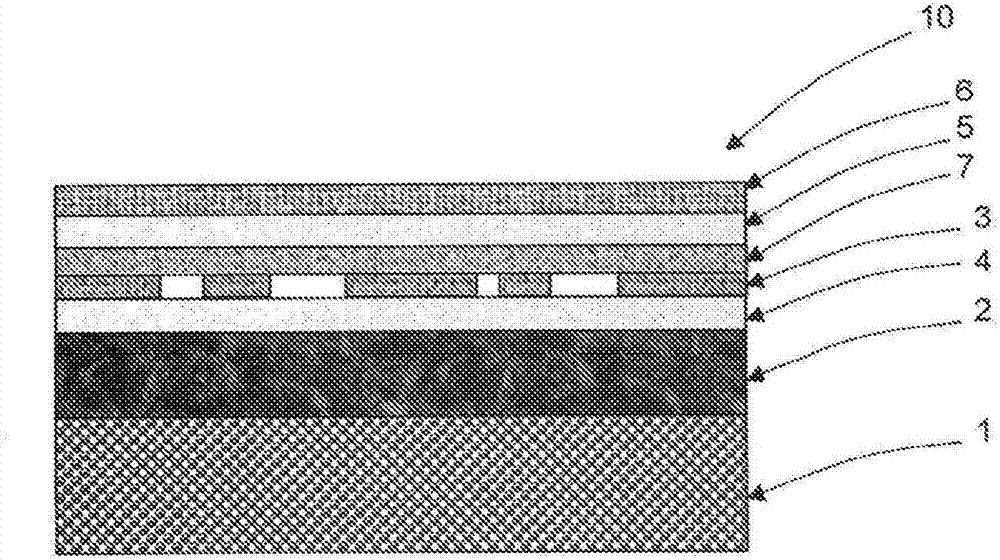

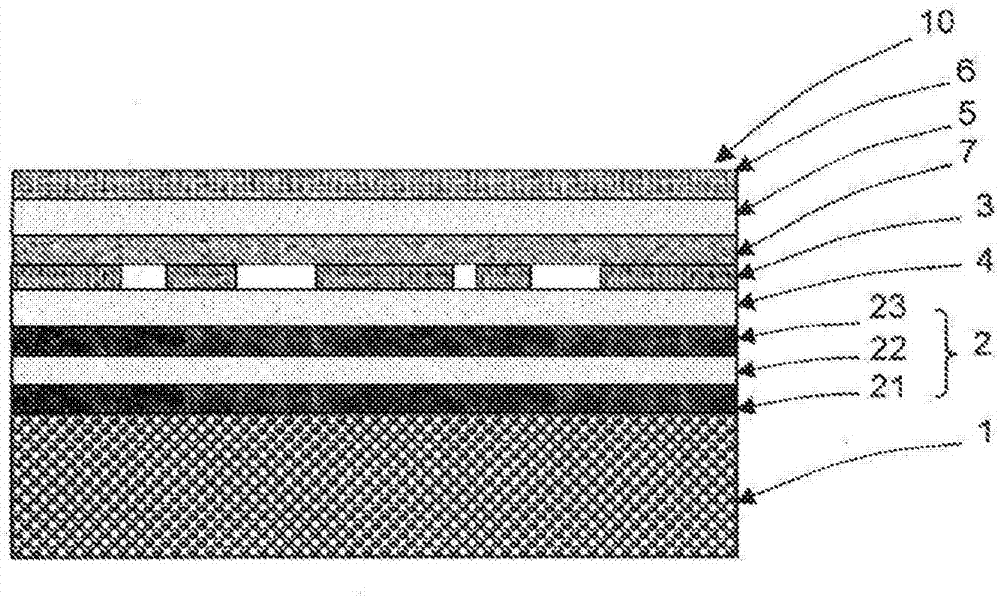

Method used

Image

Examples

Embodiment 1

[0128] A decorative layer of a stone pattern with a thickness of 2 μm was formed on a colored polypropylene resin film (thickness: 60 μm, color: white) using an ink composition (acrylic urethane) by gravure printing. Next, a transparent polypropylene resin film (thickness: 80 μm) was dry-laminated and installed on the decorative layer using a polyurethane-based dry lamination adhesive. On this transparent polypropylene resin film, by gravure printing, the coating amount is 15g / m 2 Apply an electron beam curable resin composition (acrylate type) to form a coating film, and irradiate electron beams under conditions of 175keV and 5Mrad (50kGy) to crosslink and cure the coating film to form a surface protection layer (thickness: 15μm), A decorative sheet (thickness: 160 μm) was produced.

[0129] Next, prepare a medium-density polyethylene resin sheet (tensile modulus of elasticity: 200 MPa, thickness: 3mm) as a support layer, and dry it in a manner facing the colored polypropyle...

Embodiment 2~5 and comparative example 1~2

[0132] Except having changed into the foamed resin layer and support body layer shown in Table 1 in Example 1, it carried out similarly to Example 1, and produced the decorative material for floors. Table 1 shows the results of evaluation of the obtained floor decorative material.

[0133] [Table 1]

[0134]

[0135] *1 PE1: medium density polyethylene resin sheet

[0136] PE2: Low-density polyethylene resin sheet

[0137] PVC: Glass fiber reinforced vinyl chloride board (three-layer structure of vinyl chloride resin layer / glass fiber layer / vinyl chloride resin layer, total thickness 3mm)

[0138] PP: polypropylene resin sheet

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive modulus of elasticity | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com