Chuck tape and packaging bag with chuck tape

A clamping band and band-shaped technology, which is applied in the field of clamping bands, can solve the problems of poor forming stability of the clamping band, difficult heat sealing, shape distortion of the occlusal part, etc., to achieve good shape stability and prevent shape loss , Good effect of re-opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

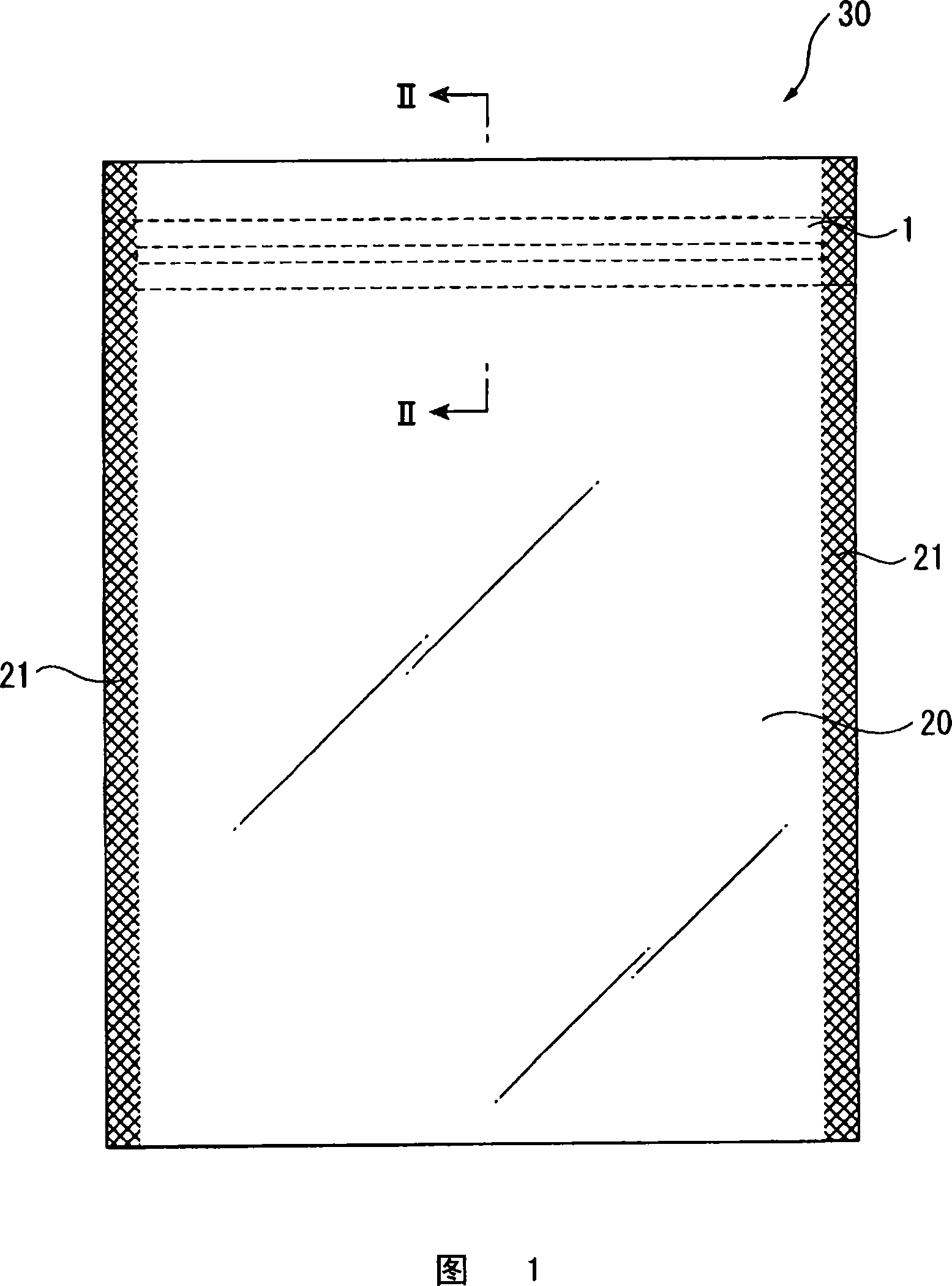

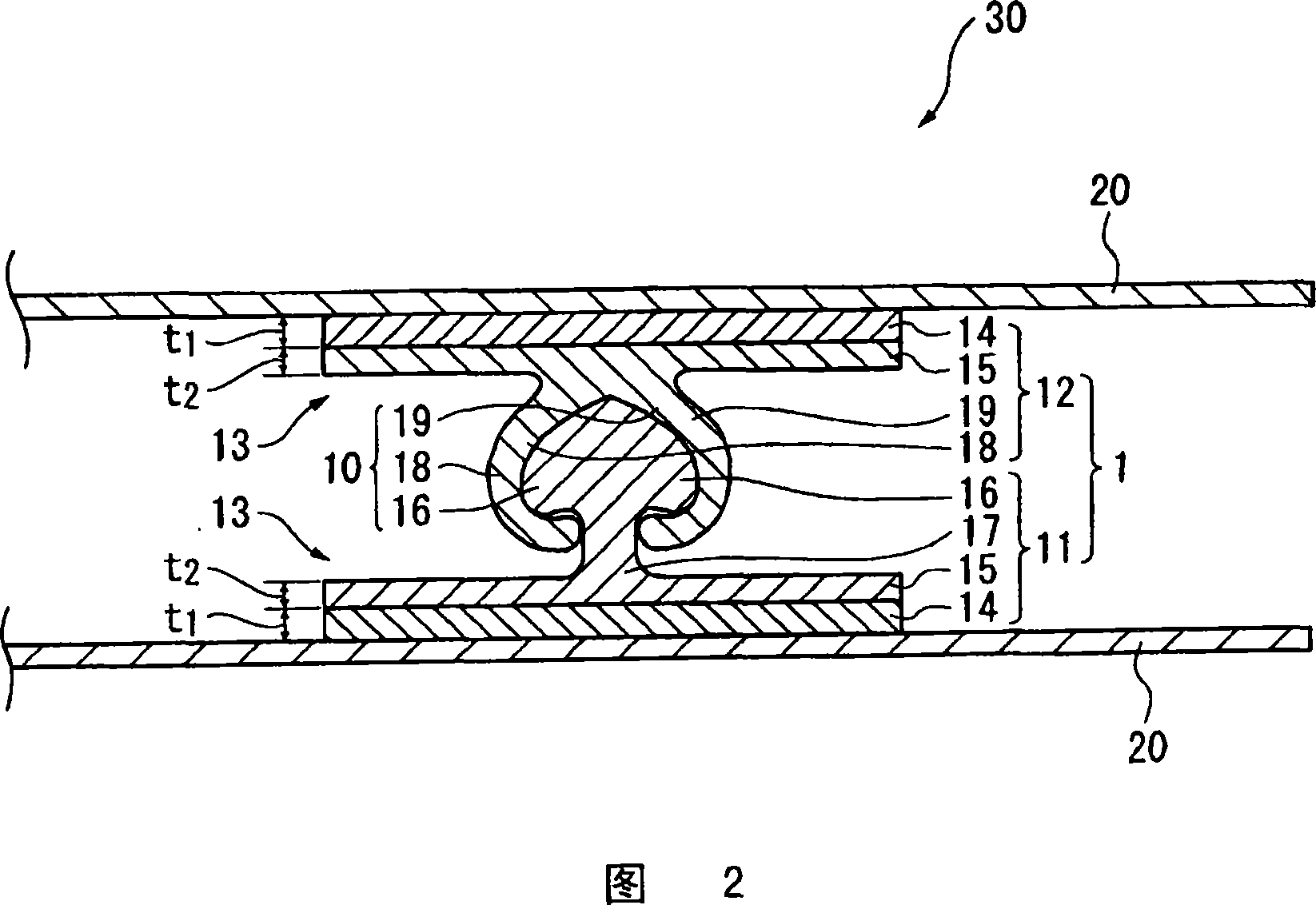

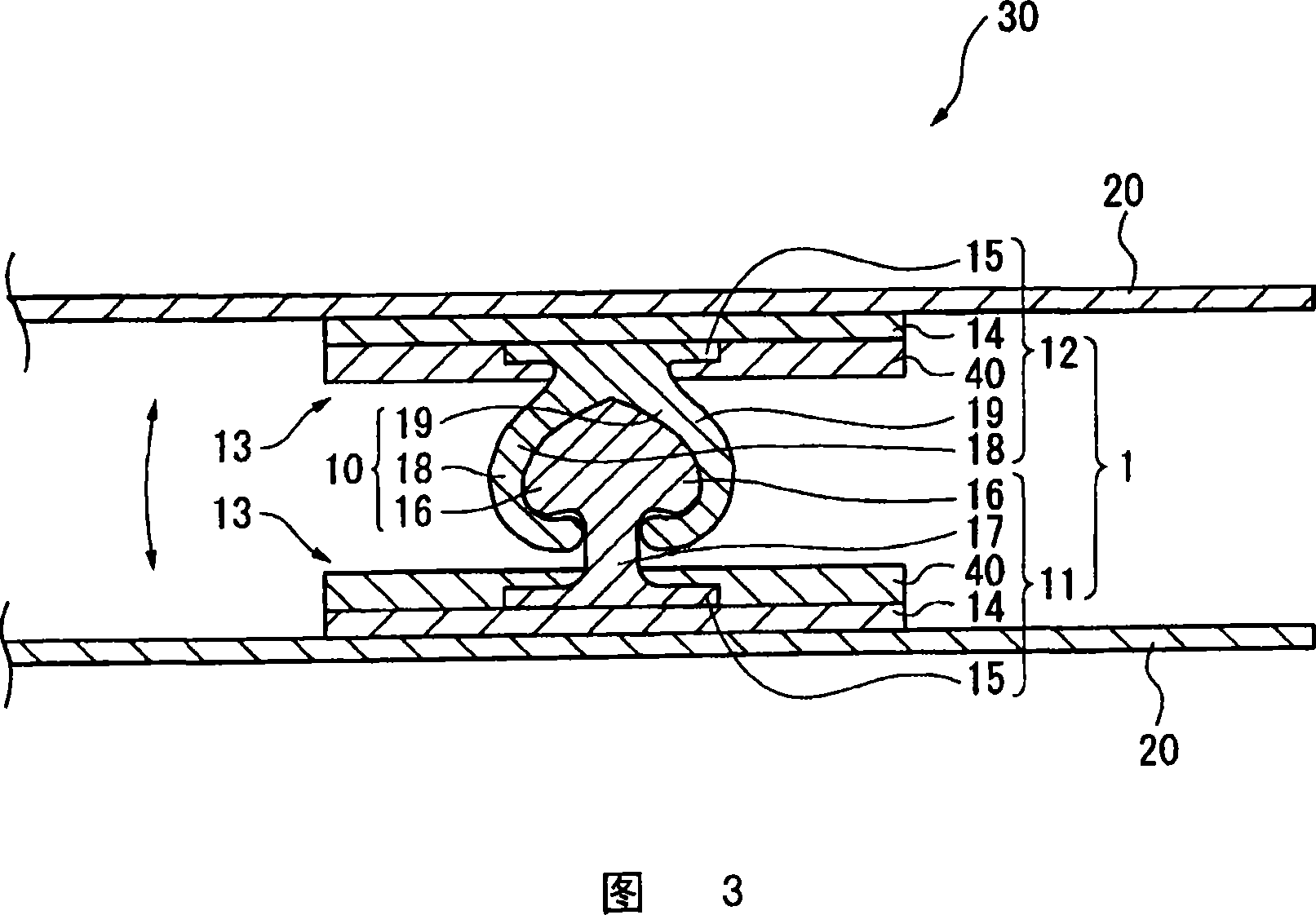

[0086] Regarding the clamp band of the shape shown in FIG. 2, the resin constituting the sealing portion and the base portion (including the occlusal portion) is set as follows, and the resin is co-extruded using two extrusion molding machines, thereby The clamping band of the present invention is obtained.

[0087] In addition, regarding the physical properties of the resin, the melting point was measured in accordance with JIS K7121, the density was measured in accordance with JIS K7121, and the melt flow rate (MFR) was measured in accordance with JIS K7210 (190°C or 230°C, 21.18N load) To measure.

[0088] (Resin used: sealing part)

[0089] The use density is 898kg / m 3 , MFR is 3.5g / 10 minutes, melting point is the metallocene linear low-density polyethylene (α-olefin is 1-hexene. Examples 2-6 are the same) (100% by mass of the whole) with a melting point of 90°C ).

[0090] (Resin used: base part)

[0091] The use density is 900kg / m 3 . MFR is 7.0 g / 10 minutes, and ...

Embodiment 2

[0094] Except for the resin that constitutes the sealing part, the use density is 900kg / m 3 , MFR is 4.0g / 10min, melting point is 95 ℃ metallocene-based linear low-density polyethylene (100% by mass of the whole), using the same method as in Example 1, the clamping of the present invention was produced. bring.

Embodiment 3

[0096] In addition to the resin that constitutes the sealing part, the density is 900kg / m 3 , MFR is 4.0g / 10min, metallocene-based linear low-density polyethylene with a melting point of 95°C is 70% by mass of the whole, and the density is 900kg / m 3 The clamping belt of the present invention was produced in the same manner as in Example 1, except that metallocene-based linear low-density polyethylene having an MFR of 20 g / 10 minutes and a melting point of 93° C. was 30% by mass of the whole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com