Cheese chestnut kernels and preparation method thereof

A technology of cheese and formula, which is applied in the direction of food ingredients as odor improvers, food ingredients as taste improvers, food science, etc. It can solve the problems of cheese and chestnut products that have not been seen, and achieve good fusion effect, good stability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

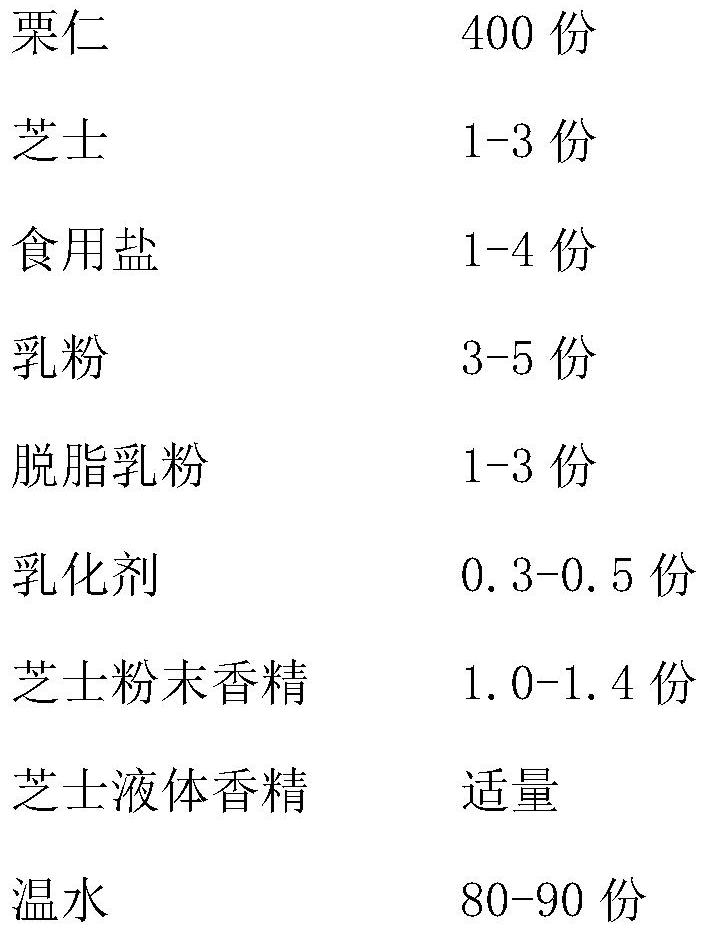

[0053] formula:

[0054]

[0055]

[0056] The emulsifier described therein consists of glyceryl monostearate, palmitic acid and stearic acid in a mass ratio of 3:1:1.

[0057] Preparation:

[0058] (1) Prepare material liquid A: mix cheese, edible salt, milk powder, skimmed milk powder, emulsifier, cheese powder flavor and warm water at 60°C, and pass through the colloid mill twice (the temperature of this process is controlled above 70°C) , to obtain feed liquid A, divide feed liquid A into feed liquid A1 and feed liquid A2, the volume ratio of feed liquid A1 to feed liquid A2 is 5:1, and set aside; the amount of cheese, milk powder, skimmed milk powder and emulsifier is the formula quantity, the consumption of edible salt and cheese powder essence is 70% of the formula quantity, and the consumption of warm water is 80% of the formula quantity;

[0059] (2) Prepare material liquid B: mix the remaining edible salt, cheese powder essence and warm water at 60°C to obtai...

Embodiment 2

[0067] formula:

[0068]

[0069] Wherein, the emulsifier is composed of glyceryl monostearate and palmitic acid in a mass ratio of 3:2.

[0070] Preparation:

[0071] With Example 1, the difference from Example 1 is that the consumption of edible salt and cheese powder essence in step (1) is 90% of the formula, the consumption of warm water is 90% of the formula, and the temperature is controlled every time the colloid mill passes through 85°C; the warm water in step (1) and step (2) is warm water at 50°C; in step (5), put it in the freezer for 24 hours; the amount of cheese liquid essence in step (6) is the frozen chestnut quality 0.3% (ml / g), the sugar coating machine runs for 3 minutes and mixes; in step (7), sterilize at 121° C. for 20 minutes.

Embodiment 3

[0073] formula:

[0074] Include the following raw materials in parts by weight:

[0075]

[0076] Wherein, the emulsifier is composed of glyceryl monostearate and stearic acid at a ratio of 4:1.

[0077] Preparation:

[0078] With embodiment 1, different from embodiment 1, the consumption of edible salt and cheese powder essence is 80% formula quantity in the step (1), and the consumption of warm water is 85% formula quantity, control temperature when passing colloid mill each time 70°C; the warm water in step (1) and step (2) is warm water at 80°C; in step (5), put it in the freezer for 48 hours; the amount of cheese liquid essence in step (6) is the frozen chestnut quality 0.2% (ml / g), the sugar coating machine runs for 3 minutes and mixes; in step (7), sterilize at 121°C for 35 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com