Method for rapidly judging silicon content in alloy

A technology of silicon content and alloy, which is applied in the detection field of silicon content in alloy, can solve the problems of uncertain test accuracy, formula method relying on experience, and lengthy test process, etc., to achieve the reduction of reagent consumption, shortening of operation process and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

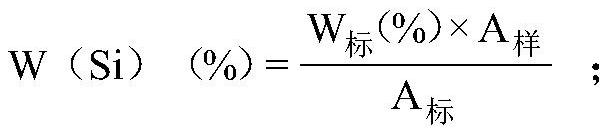

Image

Examples

Embodiment 1

[0028] The quick judgment method of silicon content in the alloy of the present embodiment comprises the following steps:

[0029] 1) For copper alloys, the acceptable range of silicon content in copper alloys is required to be [0.1wt%, 0.2wt%]. Weigh 0.0200 g of the copper alloy to be tested, 0.0200 g of the copper alloy with a known silicon content of 0.1 wt%, and 0.0200 g of a copper alloy with a known silicon content of 0.2 wt%.

[0030] Add 5ml of nitric acid to the weighed samples, heat to dissolve, then add 2ml of 10% ammonium persulfate solution, and heat to system boiling; cool to room temperature (eliminate the influence of temperature on constant volume) and then add 5% ammonium molybdate 20ml of solution, 20ml of 5% oxalic acid solution, 40ml of 5% ferrous ammonium sulfate solution, and finally set the volume in a 100ml volumetric flask, and develop color for 20min.

[0031] 2) Pipette the sample solution into a cuvette respectively, and use the solution without c...

Embodiment 2

[0037] The quick judgment method of silicon content in the alloy of the present embodiment comprises the following steps:

[0038] 1) For copper alloys, the acceptable range of silicon content in copper alloys is required to be [0.1wt%, 0.3wt%]. Weigh 0.0300g of the copper alloy to be tested, 0.0300g of the copper alloy with a known silicon content of 0.1wt%, and 0.0300g of a copper alloy with a known silicon content of 0.3wt%.

[0039]Add 5ml of nitric acid to the weighed samples, heat to dissolve, then add 2ml of 10% ammonium persulfate solution, and heat until the system boils; after cooling to room temperature, add 20ml of 5% ammonium molybdate solution and 20ml of 5% oxalic acid solution in sequence , 40ml of 5% ferrous ammonium sulfate solution, and finally set the volume in a 100ml volumetric flask, and develop color for 20min.

[0040] 2) Pipette the sample solution into a cuvette respectively, and use the solution without copper alloy as a blank control to measure th...

Embodiment 3

[0043] The quick judgment method of silicon content in the alloy of the present embodiment comprises the following steps:

[0044] 1) For copper alloys, the acceptable range of silicon content in copper alloys is required to be [0.05wt%, 0.2wt%]. 0.0100 g of the copper alloy to be tested, 0.0100 g of the copper alloy with a known silicon content of 0.05 wt %, and 0.0100 g of a copper alloy with a known silicon content of 0.2 wt % were weighed respectively.

[0045] Add 5ml of nitric acid to the weighed samples, heat to dissolve, then add 2ml of 10% ammonium persulfate solution, and heat until the system boils; after cooling to room temperature, add 20ml of 5% ammonium molybdate solution and 20ml of 5% oxalic acid solution in sequence , 40ml of 5% ferrous ammonium sulfate solution, and finally set the volume in a 100ml volumetric flask, and develop color for 20min.

[0046] 2) Pipette the sample solution into a cuvette respectively, and use the solution without copper alloy as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com