Method for separating and purifying flavonoid compounds in polygonum multiflorum leaf ethyl acetate phase through high-speed counter-current chromatography

A technology of high-speed countercurrent chromatography and flavonoids, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of large solvent consumption, poor separation effect, and large sample loss, and achieve low overall cost , small sample loss, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Preparation of Ethyl Acetate Phase of Radix Polygoni Multiflori

[0032] 1.0 kg of dried Polygonum multiflorum leaves were subjected to ultrasonic extraction with 90% ethanol as a solvent, the extraction time was 2 hours, and the solid-to-liquid ratio of ultrasonic extraction was 1:15, filtered, and the filter residue was treated twice; the filtrates were combined and subjected to vacuum Concentrate under reduced pressure until there is no ethanol smell to obtain the ethanol extract of Polygonum multiflorum leaves, and then add ethyl acetate and water for multiple extractions. The ethyl acetate phase after complete extraction was concentrated under reduced pressure in vacuo to remove the solvent to obtain the ethyl acetate phase of Radix Polygoni Multiflori.

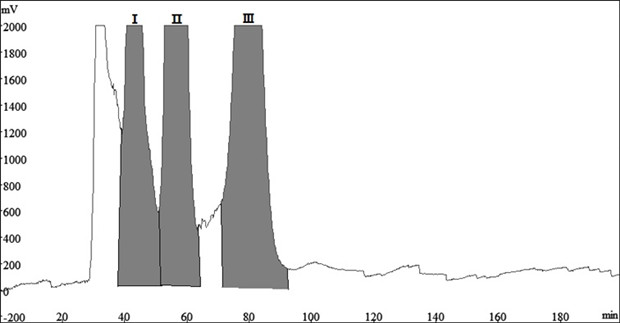

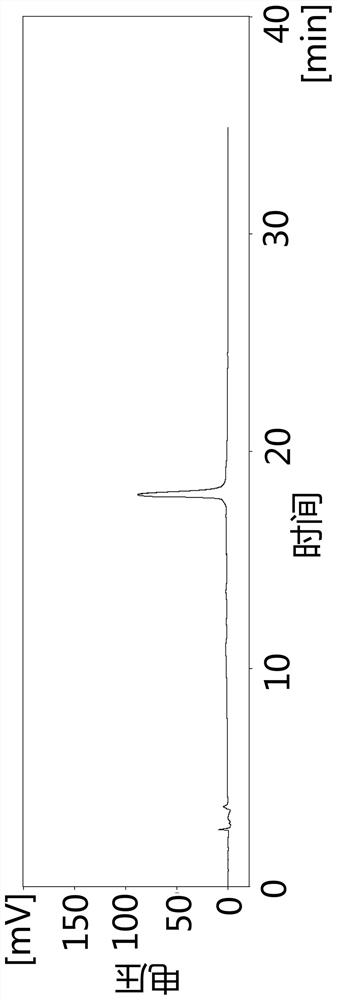

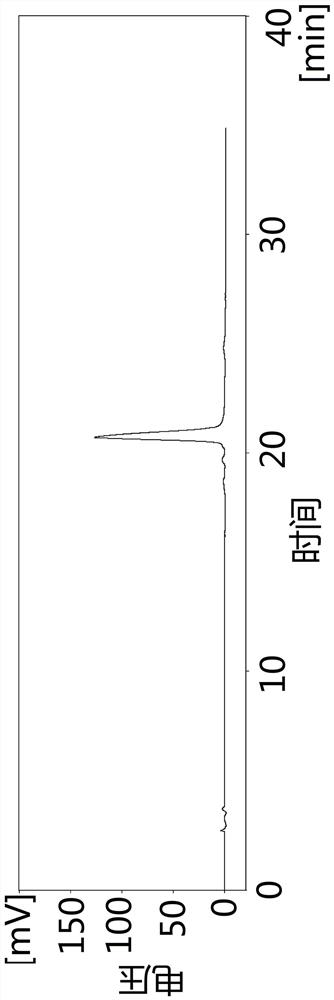

[0033] Step 2: Separation of flavonoid monomers

[0034] Use water-methanol-ethyl acetate-n-hexane with a volume ratio of 2:1:3:0.5 as the solvent system, shake well and let stand, separate the upper and ...

Embodiment 2

[0040] Step 1: Preparation of Ethyl Acetate Phase of Radix Polygoni Multiflori

[0041] 1.0 kg of dried Polygonum multiflorum leaves were subjected to ultrasonic extraction with 85% ethanol as a solvent, the extraction time was 1 h, and the solid-to-liquid ratio of ultrasonic extraction was 1:20, filtered, and the filter residue was treated once again; the filtrates were combined and subjected to vacuum Concentrate under reduced pressure until there is no ethanol smell to obtain the ethanol extract of Polygonum multiflorum leaves, and then add ethyl acetate and water for multiple extractions. The ethyl acetate phase after complete extraction was concentrated under reduced pressure in vacuo to remove the solvent to obtain the ethyl acetate phase of Radix Polygoni Multiflori.

[0042] Step 2: Separation of flavonoid monomers

[0043] Use water-methanol-ethyl acetate-n-hexane with a volume ratio of 2:2:4:0.5 as the solvent system, shake well and let stand, separate the upper and...

Embodiment 3

[0047] Step 1: Preparation of Ethyl Acetate Phase of Radix Polygoni Multiflori

[0048] 1.0 kg of dried Polygonum multiflorum leaves were subjected to ultrasonic extraction with 95% ethanol as a solvent, the extraction time was 3 hours, the solid-to-liquid ratio of ultrasonic extraction was 1:10, filtered, and the filter residue was treated twice; the filtrates were combined and subjected to vacuum Concentrate under reduced pressure until there is no ethanol smell to obtain the ethanol extract of Polygonum multiflorum leaves, and then add ethyl acetate and water for multiple extractions. The ethyl acetate phase after complete extraction was concentrated under reduced pressure in vacuo to remove the solvent to obtain the ethyl acetate phase of Radix Polygoni Multiflori.

[0049] Step 2: Separation of flavonoid monomers

[0050] Use water-methanol-ethyl acetate-n-hexane with a volume ratio of 2:1:4:1 as the solvent system, shake well and let stand, separate the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com