Cobalt tungstate/bismuth composite acoustic catalyst as well as preparation method and application thereof

A technology of cobalt tungstate and composite sound, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of limitation, easy recombination of photogenerated charges, etc., and achieve low cost and good acoustic catalytic activity , The effect of low carrier density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

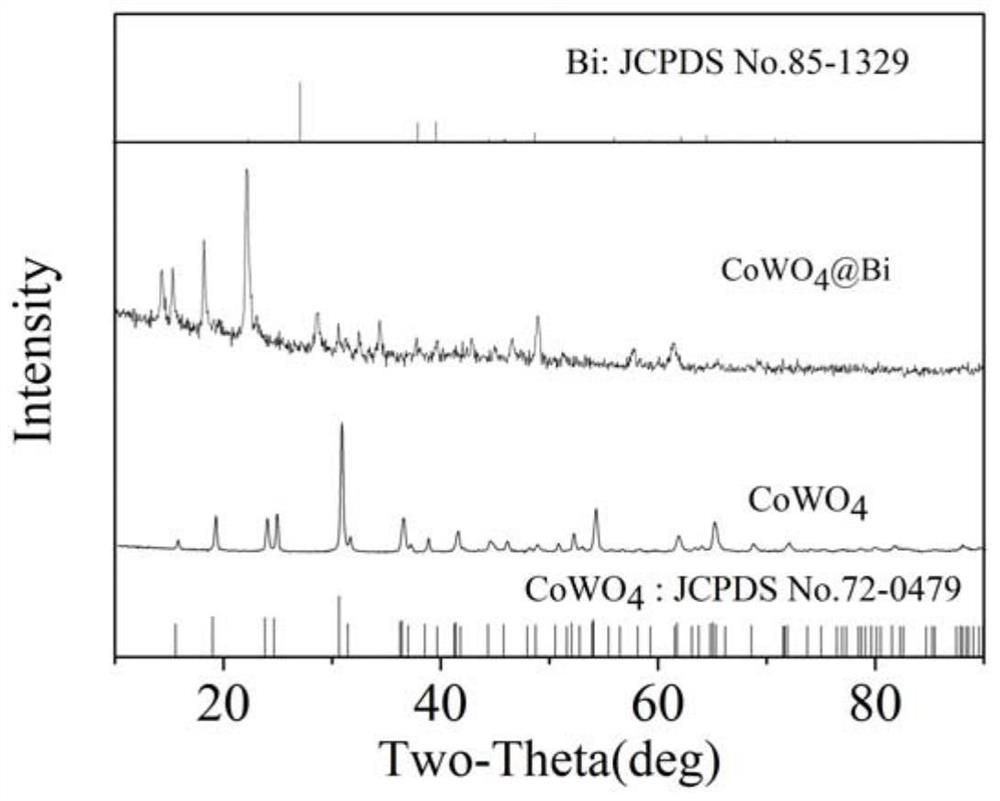

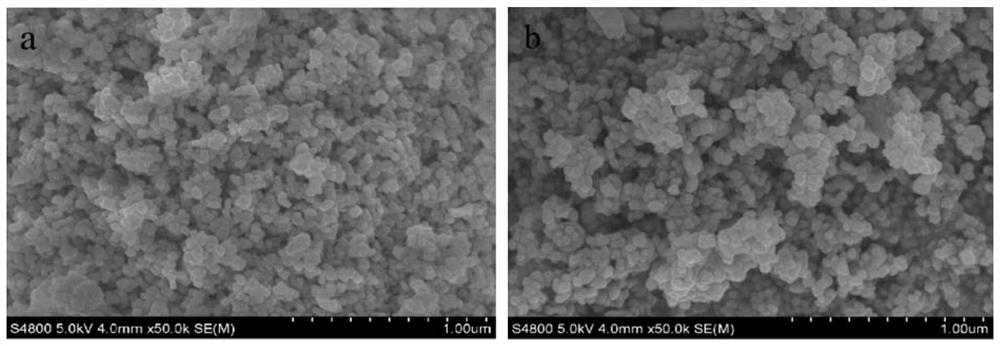

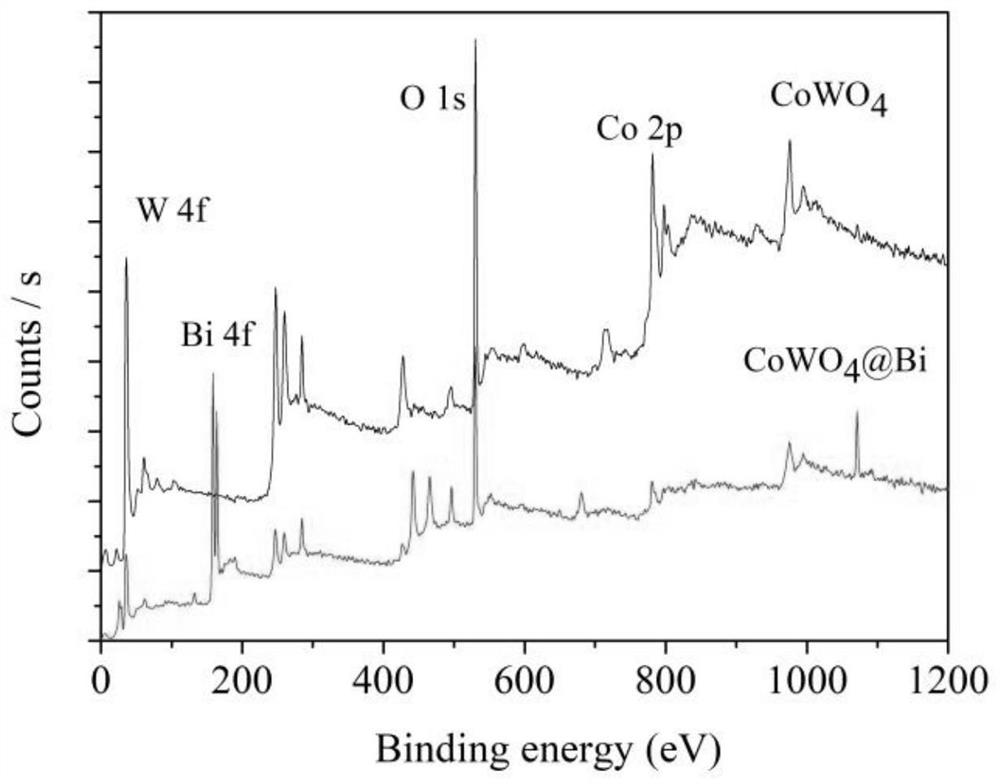

[0026] Embodiment 1 cobalt tungstate / bismuth composite acoustic catalyst (one) preparation method is as follows:

[0027] 1) CoWO 4 Preparation: 1.4551g Co(NO 3 ) 2 ·6H 2 O and 1.6493g Na 2 WO 4 2H 2 O was dissolved in a 100mL Erlenmeyer flask with 30mL of deionized water respectively; the two were mixed, and the mixture was magnetically stirred for 30min; after ultrasonic reaction for 30min, it was poured into a polytetrafluoroethylene reactor, and placed in a blast drying oven for 180 ℃ for 24 hours; after the reaction, filter with suction, dry at 80℃ for 2 hours, grind into a fine powder with an agate mortar, and obtain CoWO 4 powder.

[0028] 2) Measure 10.5993g NaPO 2 h 2 ·H 2 O was dissolved in an Erlenmeyer flask containing 50 mL of deionized water, and after magnetic stirring for 20 min, 0.45027 g of C was added 4 h 4 o 6 and 0.08g NaOH, after magnetic stirring for 30min, add 0.375g, 0.75g, 1.5g, 3g CoWO 4 , sonicated for 30min to obtain different CoWO 4...

Embodiment 2

[0035] Example 2CoWO 4 Effect of / Bi Composite Acoustic Catalyst on Catalytic Ultrasonic Degradation of Tetracycline Solution

[0036] Method: Weigh CoWO respectively 4 with Bi(NO 3 ) 3 ·5H 2 O cobalt tungstate / bismuth composite material CoWO with different molar ratios 4 / Bi each 20mg, add 20mL tetracycline solution with a concentration of 20mg / L, ultrasonic catalysis for 2h, ultrasonic power 200W, ultrasonic temperature 20°C. After the treated suspension is sampled and centrifuged, the supernatant is taken, and its UV-vis spectrum is measured within 200-400nm. The degradation rate of the tetracycline solution can be measured at its λ max = Absorbance at 351nm to calculate,

[0037] Formula is: degradation rate (%)=[(A 0 -A t ) / A 0 ]×100%

[0038] A 0 is the initial absorbance of the tetracycline solution;

[0039] A t is the absorbance of tetracycline solution under different experimental conditions;

[0040] The result is as Figure 4 As shown, when CoWO 4 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com