Preparation method and production line of original taste instant radix puerariae powder

A production line and instant technology, applied in grain processing, food processing, food drying, etc., can solve problems such as adverse effects of nutritional and health substances, difficulty in maintaining the quality and style of original juice and original leaves, achieve automation and intelligence, and solve difficult removal , To ensure the effect of product quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

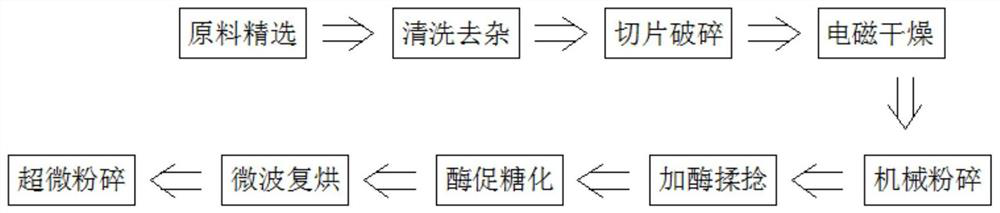

[0034] like figure 1 As shown, a kind of preparation method steps of original flavor instant Pueraria lobata powder are as follows:

[0035] (1) Selection of raw materials: select fresh kudzu root without rot, mildew.

[0036] (2) Cleaning and removing impurities: Input the selected kudzu root into a high-pressure drum peeling and washing machine, rinse, peel and remove impurities, wash the leather coat and sediment and worm eggs on the surface of the kudzu root, and remove the brown pigment on the outer epidermis. and bitter substances.

[0037] (3) Mechanical slicing: Put the cleaned kudzu root into a slicer and cut into 3-5 mm thin slices for drying and crushing.

[0038] (4) Electromagnetic drying: Input the sliced kudzu root into an electromagnetic dryer, set the drying temperature to be 120 to 125°C, and the time to be 8 to 10 minutes, and use electromagnetic induction heating to dry the moisture inside and outside the kudzu root to make it a Dried kudzu flakes with...

Embodiment 2

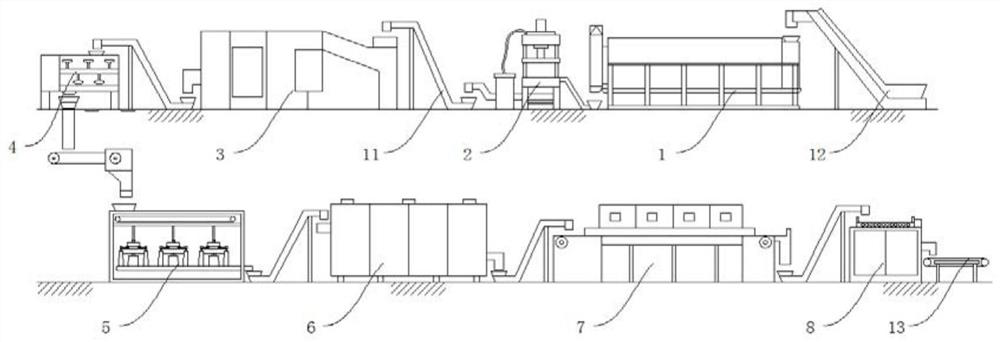

[0046] like figure 2 As shown in the figure, a production line for the preparation of plain instant kudzu powder includes a washing machine 1, a slicer 2, an electromagnetic dryer 3, a pulverizer 4, a kneading unit 5, a saccharification unit 6, a microwave dryer 7 and an ultrafine pulverizer 8. The above-mentioned equipments are connected in sequence through the belt conveyor 11 , the washing machine 1 is connected with the raw material conveyor 12 , and the ultrafine pulverizer 8 is connected with the discharge conveyor 13 .

[0047] The raw material conveyor 12 is a "Z-shaped" hoisting conveyor, which adopts a conveyor belt made of stainless steel and is equipped with an electronic weighing device, which can automatically weigh and transport the raw materials of kudzu.

[0048] The cleaning machine 1 adopts a high-pressure drum washing machine, which consists of a cleaning drum, a high-pressure spray device, a cleaning device, a material turning device, a draining device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com