Solid-state battery and preparation method thereof

A solid-state battery and preparation process technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., and can solve problems such as poor stability of pole pieces, large internal resistance of batteries, limited manufacturing temperature and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

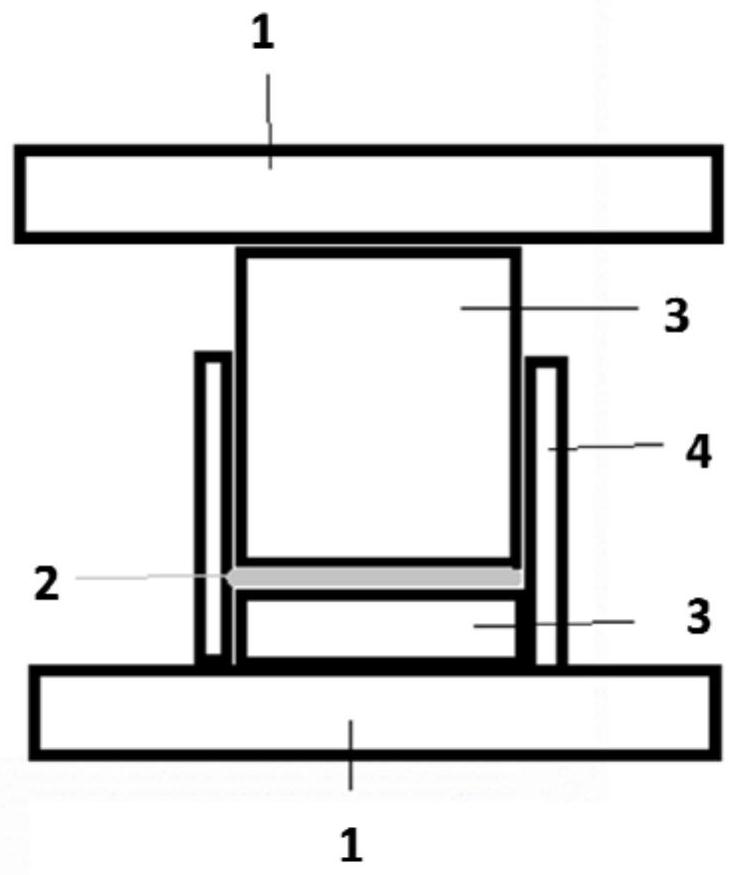

[0050] An embodiment of the present invention provides a method for preparing a solid-state battery. The preparation process of the solid-state battery is carried out under anhydrous and oxygen-free conditions, including the following steps:

[0051] S10. obtaining a porous metal material;

[0052] S20. Mixing the metal nanomaterial, the positive electrode powder and the first electrolyte powder to obtain a positive electrode mixture;

[0053] S30. Filling the positive electrode mixture into the structure of the porous metal material, and performing the first compaction treatment to obtain a positive electrode compacted layer;

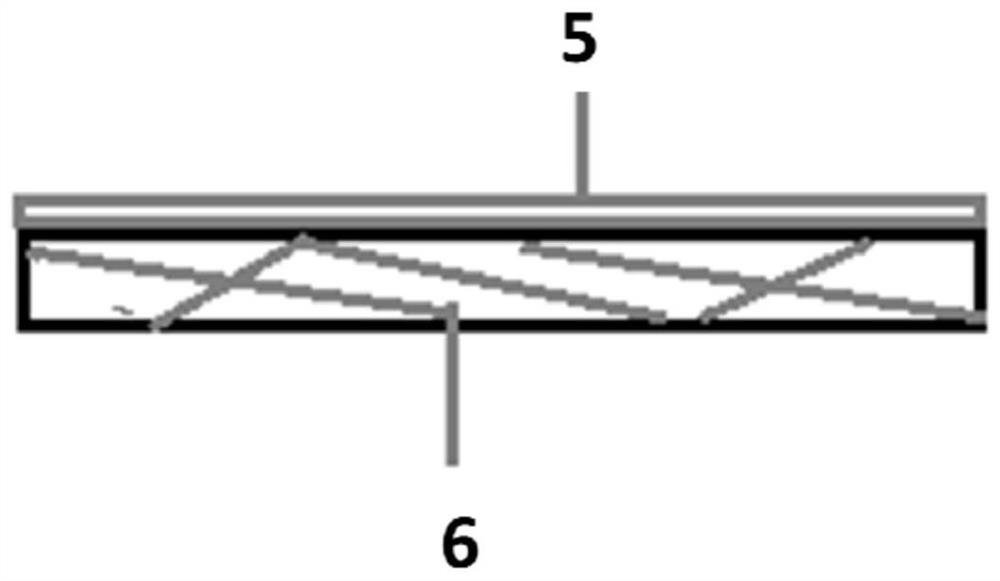

[0054] S40. Deposit the second electrolyte powder on one side of the positive electrode compacted layer, and perform a second compaction treatment to obtain a composite compacted layer of the positive electrode compacted layer and the electrolyte compacted layer;

[0055] S50. Electromagnetic thermal sintering is performed on the composite compacted l...

Embodiment 1

[0106] A solid state battery comprising the steps of:

[0107] ① Operate under an inert atmosphere environment, mix ferrous sulfide FeS cathode powder, Li 7 P 3 S 11 The sulfide electrolyte and metal iron nano powder conductive agent are ball milled to obtain the mixture;

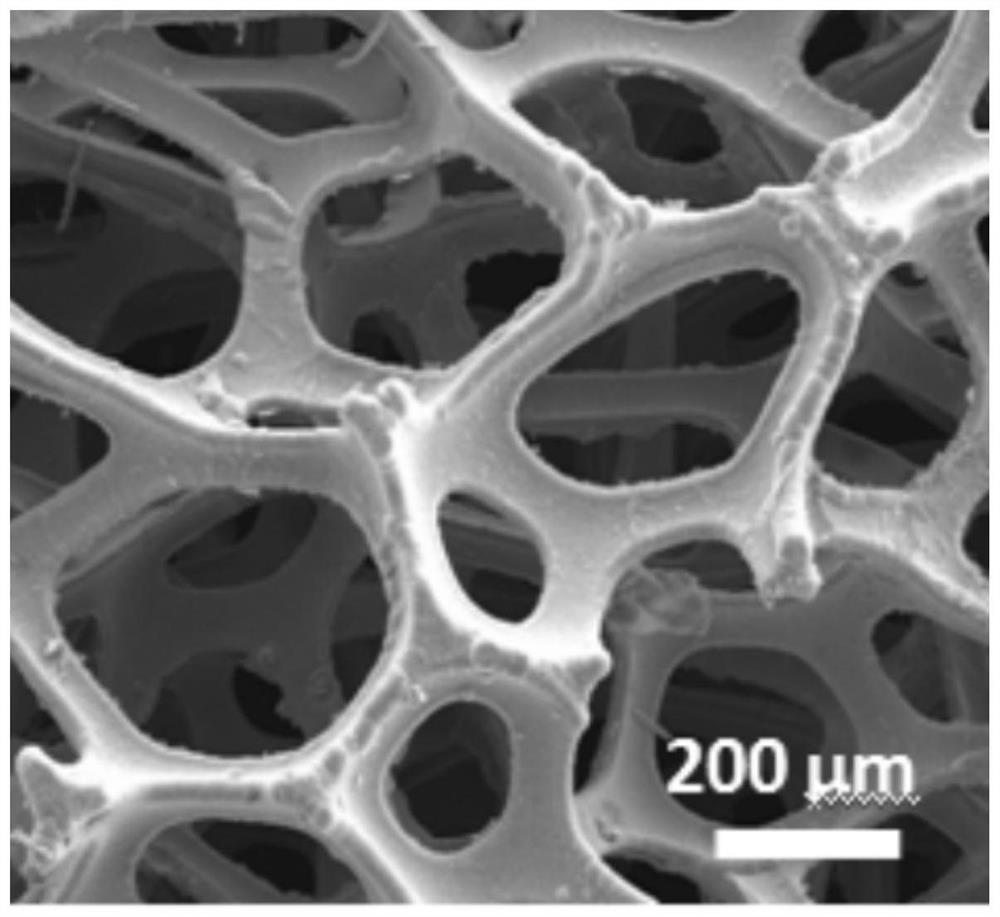

[0108] ②Fill the mixture in step ① into metal foam nickel with a thickness of 200 microns, as attached figure 2 It can be seen from the electron microscope image that the thickness of metal foamed nickel is 100 microns to 600 microns, and the opening diameter is 0.25 mm, and the vibration makes the pole pieces packed tightly;

[0109] ③ Place the metal foam nickel mesh in a metal module of predetermined size and shape, fill the positive electrode powder into the metal foam nickel mesh supported by the bottom metal plane, put it into a hydraulic mold, and apply pressure to make it a whole The thickness of the pole piece without falling powder is reduced, and the original 150 micron thick foam network is...

Embodiment 2

[0115] A solid state battery comprising the steps of:

[0116] ① Operate under an inert atmosphere environment, according to the ratio of 65%: 30%: 5% FeS 2 Cathode powder, Li 7 P 3 S 11 Sulfide electrolyte, metal nickel nano powder conductive agent ball milling to obtain the mixture;

[0117] ②Fill the mixture in step ① into metal foam nickel with a thickness of 200 microns, the thickness of the metal foam nickel is 100 microns to 600 microns, and the opening aperture is 0.25 mm, and the vibration makes the pole pieces packed tightly;

[0118] ③ Place the metal foam nickel mesh in a metal module of predetermined size and shape, fill the positive electrode powder into the metal foam nickel mesh supported by the bottom metal plane, put it into a hydraulic mold, and apply pressure to make it a whole The thickness of the pole piece without powder falling is reduced, and the original 200 micron thick foam network is reduced to 160 micron.

[0119] ④ Add electrolyte powder and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com