Multi-scale particle modified Al-Mg alloy welding wire and preparation method thereof

An alloy welding wire, multi-scale technology, applied in welding equipment, metal processing equipment, welding medium, etc., can solve problems such as welding hot cracks and insufficient weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

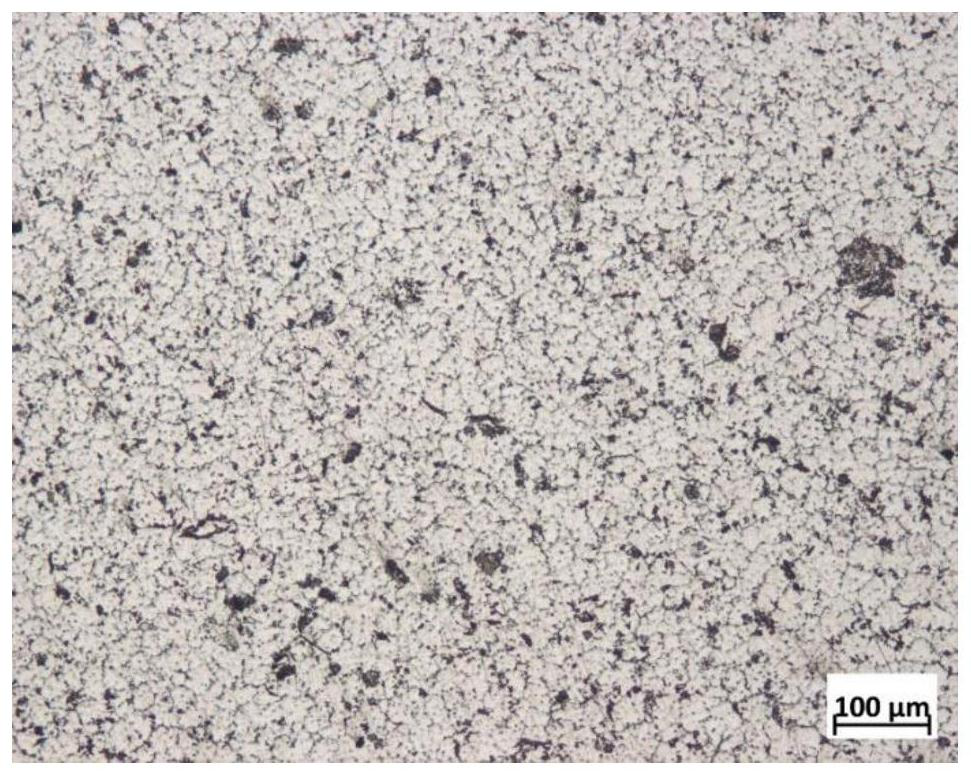

[0032] Embodiment 1: Its preparation method of the Al-Mg alloy welding wire of a kind of multi-scale particle modification, comprises the following steps:

[0033] Step 1: Select material: Mg: 5.5%; Mn: 1.0%; Cr: 0.05%; Cu: 1.0%; TiB 2 : 0.5%; TiC: 3.5%; the rest is Al and unavoidable impurity elements;

[0034] Step 2: Preparation of TiB containing submicron 2 Aluminum master alloys of particles and nanoscale TiC particles;

[0035] Step 3: Add submicron TiB 2 Aluminum master alloys of particles and nanoscale TiC particles, Al-Cr, Al-Cu and other master alloys are smelted in a melting furnace with a temperature controlled at 800-820°C and protected by an inert gas. After complete melting, add Mg and stir well uniform, and then carry out the melt purification process of refining degassing and slag removal;

[0036] Step 4: The controlled alloy melt after melt purification is introduced into the tundish for heat preservation at 800-820°C, and injected into the continuous se...

Embodiment 2

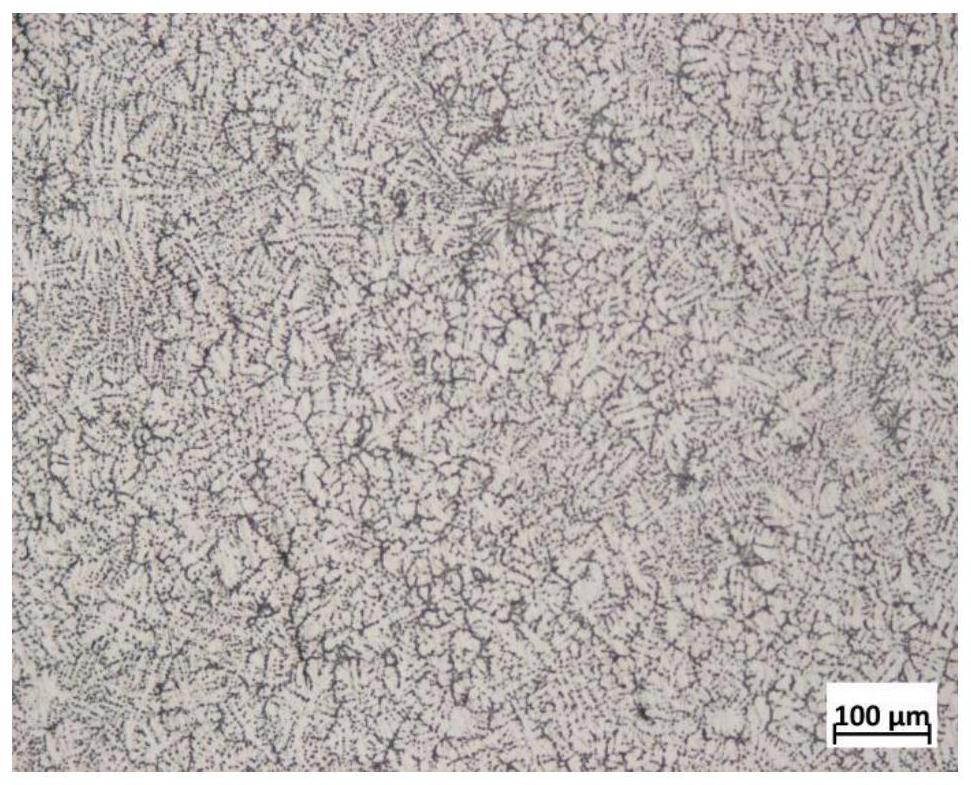

[0038] Embodiment 2: Its preparation method of the Al-Mg alloy welding wire of a kind of multi-scale particle modification, comprises the following steps:

[0039] Step 1: Select material: Mg: 7.5%; Mn: 0.1%; Cr: 0.05%; Cu: 0; TiB 2 : 3.5%; TiC: 0.5%; the rest is Al and unavoidable impurity elements;

[0040] Step 2: Preparation of TiB containing submicron 2 Aluminum master alloys of particles and nanoscale TiC particles;

[0041] Step 3: Add submicron TiB 2 Aluminum master alloys and Al-Cr master alloys with particles and nanoscale TiC particles are melted in a melting furnace with a temperature controlled at 780°C and protected by an inert gas. After complete melting, Mg is added, fully stirred evenly, and then refined to remove Melt purification process for gas deslagging;

[0042] Step 4: The controlled alloy melt after melt purification is introduced into the tundish for heat preservation at 760-800°C, and injected into the continuous semi-solid rheological extruder a...

Embodiment 3

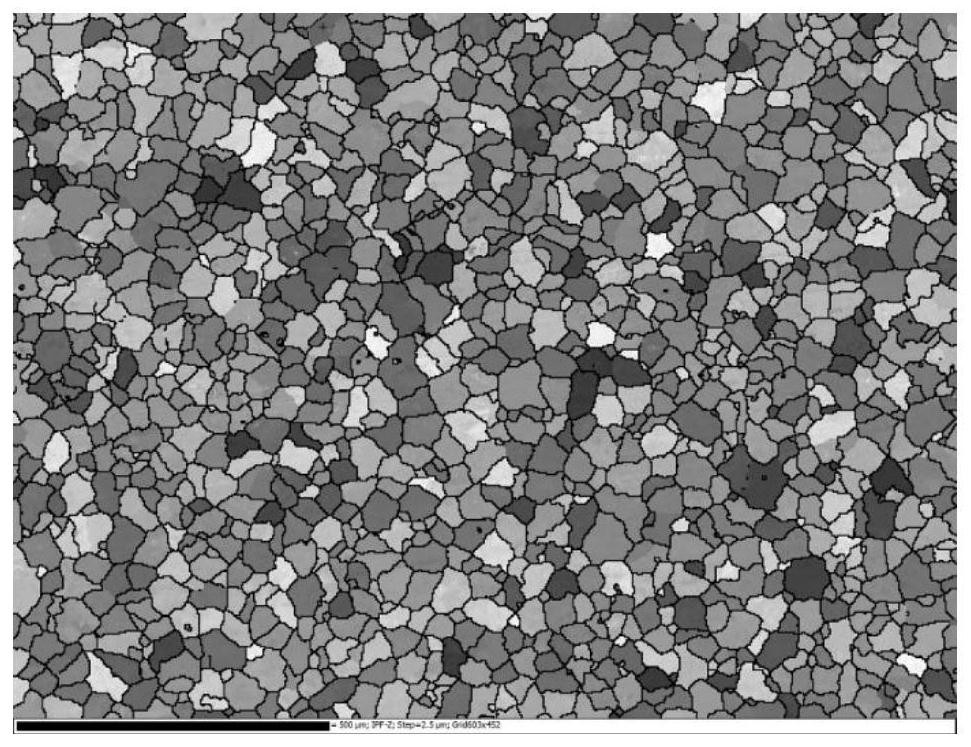

[0044] Embodiment 3: Its preparation method of the Al-Mg alloy welding wire of a kind of multi-scale particle modification, comprises the following steps:

[0045] Step 1: Select material: Mg: 6.5%; Mn: 0.3%; Cr: 0.1%; Cu: 0.5%; TiB 2 : 1%; TiC: 2.5%; the rest is Al and unavoidable impurity elements;

[0046] Step 2: Preparation of TiB containing submicron 2 Aluminum master alloys of particles and nanoscale TiC particles;

[0047] Step 3: Add submicron TiB 2 Aluminum master alloys of particles and nanoscale TiC particles, Al-Cr, Al-Cu and other master alloys are smelted in a melting furnace with a temperature controlled at 760-820°C and protected by an inert gas. After complete melting, add Mg and stir well uniform, and then carry out the melt purification process of refining degassing and slag removal;

[0048] Step 4: The controlled alloy melt after melt purification is introduced into the tundish for heat preservation at 780-820°C, and injected into the continuous semi-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com