Monodisperse mesoporous silica composite zeolite core-shell material and preparation method thereof

A mesoporous silica and composite zeolite technology, applied in chemical instruments and methods, molecular sieve catalysts, fatty acid esterification, etc., can solve problems such as deactivation and small surface pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

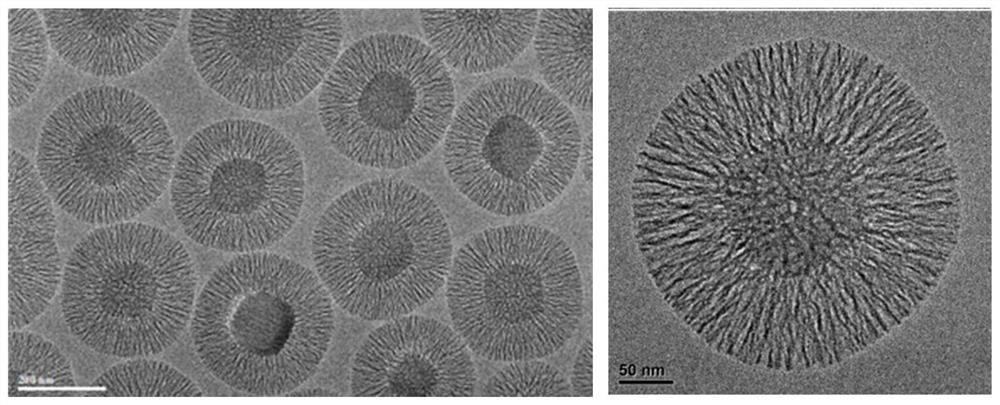

[0035] A monodisperse mesoporous silica composite zeolite core-shell nanosphere material, the core is nano-scale zeolite crystal grains, and the shell is radial-shaped mesoporous channel silica. Prepared by the following method:

[0036] Dissolve 5 g of tetramethylammonium hydroxide and 0.75 g of aluminum isopropoxide in 7 g of water, and then add a pre-prepared aqueous solution of ethyl orthosilicate (2.25 g of ethyl orthosilicate mixed with 2 g of water ), after stirring at room temperature for 5 minutes, add 0.6 g of 1M aqueous sodium hydroxide solution, continue stirring at room temperature for 5 hours, and move to a hydrothermal kettle. Place in an oven at 80°C for 72 hours. After the reaction is finished, it is naturally cooled to room temperature, and washed three times with ethanol and water to obtain LTA-type zeolite grains, which are then dried for use.

[0037] 10 g of cetyltrimethylammonium bromide, 100 mg of LTA zeolite grains and 0.8 mL of triethanolamine were ...

Embodiment 2

[0039] A preparation method of a monodisperse mesoporous silica composite zeolite core-shell nanosphere material, comprising:

[0040] Dissolve 0.63 g of tetrapropylammonium hydroxide and 1.6 g of ethanol completely in 4.2 g of water, then add 1.8 g of tetraethyl orthosilicate to it, stir at room temperature for 24 hours, and move to a hydrothermal kettle. Place in a 90°C oven and heat for 48 hours. After the reaction was completed, it was naturally cooled to room temperature, and washed three times with ethanol and water to obtain MFI zeolite grains with a size of 40 nm, which were redispersed in water for later use.

[0041] Dissolve 8 g of cetyltrimethylammonium chloride, 120 mg of MFI zeolite grains and 0.75 mL of triethanolamine into 150 mL of deionized water successively, and ultrasonically stir evenly to form a pale white homogeneous and transparent aqueous phase solution; Put the solution into the reactor, stir at 80°C for 0.5 hours; take another 1 ml of fumed silica ...

Embodiment 3

[0043] A method for preparing a monodisperse mesoporous silica composite zeolite core-shell nanosphere material, comprising:

[0044] Completely dissolve 8.1 g of tetrapropylammonium hydroxide in 40 g of water, then add 23 g of ethyl orthosilicate therein, stir at room temperature for 3 hours, and move to a hydrothermal kettle. Put it in an oven at 120°C and heat it for 2 hours, then raise the temperature to 170°C and heat it for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and washed three times with ethanol and water to obtain MFI type zeolite crystal grains with a size of 100 nm, which were dried for later use.

[0045] 2 g of octadecyltrimethylammonium chloride, 20 mg of MFI zeolite grains and 0.5 mL of triethanolamine were successively dissolved in 36 mL of deionized water, and ultrasonically stirred evenly to form a pale white homogeneous and transparent aqueous phase solution; Put the solution into the reactor, and stir at 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com