Anticoagulant coating composition as well as preparation method and application thereof

A coating composition and anticoagulant technology, applied in the field of biomedical materials, can solve the problems of long-lasting anticoagulant effect, decreased anticoagulant activity of heparin, weakened anticoagulant activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

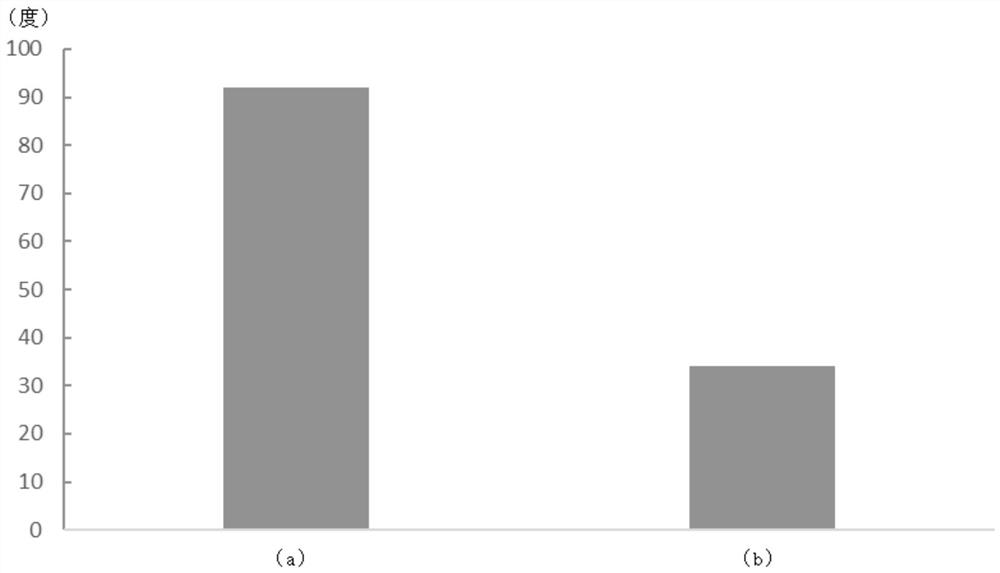

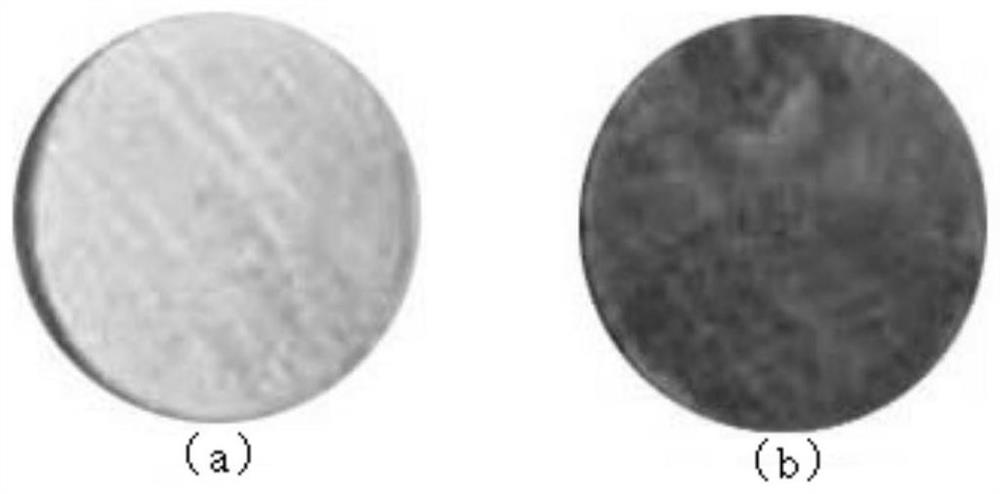

Image

Examples

Embodiment 1

[0041] Preparation of functional polyether long-chain quaternary ammonium salt polymer materials:

[0042] Preparation of polymer precursor: MeBr 4 Ox monomer (0.1 mol), MeAE 12 Ox (0.2 mol), Catalyst BF 3 •Et 2 O (4.1 mmol), the initiator pentaerythritol (1.0 mmol) was dissolved in anhydrous dichloromethane, reacted in an ice bath for 24 hours, after the reaction was completed, it was washed with acid, salt, and water, and the solvent was removed by rotary evaporation. Vacuum dried for 48h to obtain P[(MeBr 4 Ox)- co -( MeAE 12 Ox)] polymer precursor, yield 90%;

[0043]Preparation of functional polyether long-chain quaternary ammonium salt polymer material: the P[(MeBr obtained above 4 Ox)- co -(MeAE 12 Ox)] Add the polymer precursor to anhydrous acetonitrile solvent, then add N, N-dimethyl octadecylamine (42.7g, 0.2mol), reflux under nitrogen environment for 15h, after the reaction is completed, refine and purify by high vacuum vacuum distillation Discharging to...

Embodiment 2

[0048] Preparation of functional polyether long-chain quaternary ammonium salt polymer solution: Dissolve 20g of functional polyether long-chain quaternary ammonium salt polymer material in 100mL water to prepare 20% (w / v) functional polyether long-chain quaternary ammonium salt Salt polymer solution;

[0049] Prepare heparin sodium solution: dissolve 10g heparin sodium in 100mL water to prepare 10% (w / v) heparin sodium solution;

[0050] Preparation of functional polyether long-chain quaternary ammonium salt polymer-heparin composition: under stirring conditions, add the functional polyether long-chain quaternary ammonium salt polymer solution dropwise to 10% under stirring conditions (w / v) concentration of heparin sodium solution, a white precipitate of the composition was obtained; then the white precipitate was separated by suction filtration, washed with water three times, and finally the white precipitate was vacuum-dried for 24 hours to obtain a functional polyether lon...

Embodiment 3

[0052] Preparation of functional polyether long-chain quaternary ammonium salt polymer solution: Dissolve 50g of functional polyether long-chain quaternary ammonium salt polymer material in 100mL water to prepare 50% (w / v) functional polyether long-chain quaternary ammonium salt Salt polymer solution;

[0053] Prepare heparin sodium solution: dissolve 20g heparin sodium in 100mL water to prepare 20% (w / v) heparin sodium solution;

[0054] Preparation of functional polyether long-chain quaternary ammonium salt polymer-heparin composition: under stirring conditions, add the functional polyether long-chain quaternary ammonium salt polymer solution dropwise to 20% under stirring conditions (w / v) concentration of heparin sodium solution, a white precipitate of the composition was obtained; then the white precipitate was separated by suction filtration, washed with water three times, and finally the white precipitate was vacuum-dried for 24 hours to obtain a functional polyether lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com