Method for improving electrical performance of GaN vertical Schottky diode with strip-shaped groove structure based on self-alignment process

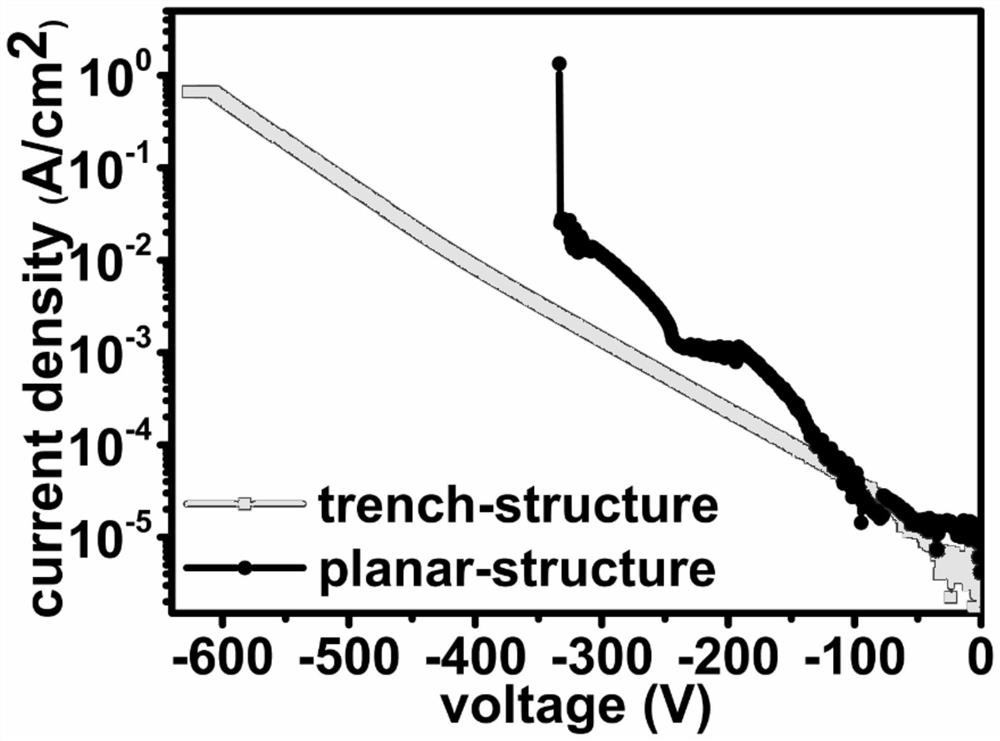

A Schottky diode, self-aligned process technology, applied in diodes, circuits, electrical components, etc., can solve the problems of reducing device performance and application, large reverse leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] S1 Ultrasonic cleaning the self-supporting substrate GaN in acetone, absolute ethanol, and deionized water in sequence;

[0046] S2. Prepare a mask with an etching thickness of 1 μm in AZ6130 photoresist on the surface of the GaN cleaned in step S1 using a standard photolithography process;

[0047] S3, performing an alignment mark etching experiment on the GaN of the etching mask in step S2 using an inductively coupled plasma ICP dry etching process;

[0048] S4. After the alignment mark etching in step S3 is completed, the Ti / Al / Ni / Au metal layer is evaporated on the back of the GaN substrate by electron beam technology, with a thickness of 200nm, and is treated by RTA rapid annealing equipment at 750°C and Ar environment 20s to form a corresponding ohmic contact;

[0049] S5. Use photolithography and electron beam technology to make ohmic contact with the prepared GaN substrate front side in step S4, and prepare a strip-shaped metal Ni mask with a thickness of 200nm...

Embodiment 2

[0055] S1 Ultrasonic cleaning the self-supporting substrate GaN in acetone, absolute ethanol, and deionized water in sequence;

[0056] S2. Prepare a mask with an etching thickness of 1.5 μm of AZ6130 photoresist on the surface of the GaN cleaned in step S1 by a standard photolithography process;

[0057] S3, performing an alignment mark etching experiment on the GaN of the etching mask in step S2 using an inductively coupled plasma ICP dry etching process;

[0058] S4. After the etching of the alignment mark in step S3 is completed, a Ti / Al / Ni / Au metal layer is evaporated on the back of the GaN substrate by an electron beam process, with a thickness of 300nm, and is treated by RTA rapid annealing equipment at 850°C and Ar environment 30s to form a corresponding ohmic contact;

[0059] S5. Using photolithography and electron beam technology to ohm-contact the front side of the prepared GaN substrate in step S4, prepare a 300nm strip-shaped metal Ni mask, and the corresponding...

Embodiment 3

[0065] S1 Ultrasonic cleaning the self-supporting substrate GaN in acetone, absolute ethanol, and deionized water in sequence;

[0066] S2. Prepare a mask with an etching thickness of 1.2 μm of AZ6130 photoresist on the surface of the GaN cleaned in step S1 by using a standard photolithography process;

[0067] S3, performing an alignment mark etching experiment on the GaN of the etching mask in step S2 using an inductively coupled plasma ICP dry etching process;

[0068] S4. After the alignment mark etching in step S3 is completed, the Ti / Al / Ni / Au metal layer is evaporated on the back of the GaN substrate by electron beam technology, with a thickness of 240nm, and is treated by RTA rapid annealing equipment at 790°C and Ar environment 24s to form a corresponding ohmic contact;

[0069] S5. Use photolithography and electron beam technology to make ohmic contact with the front side of the prepared GaN substrate in step S4, and prepare a 240nm strip-shaped metal Ni mask, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com