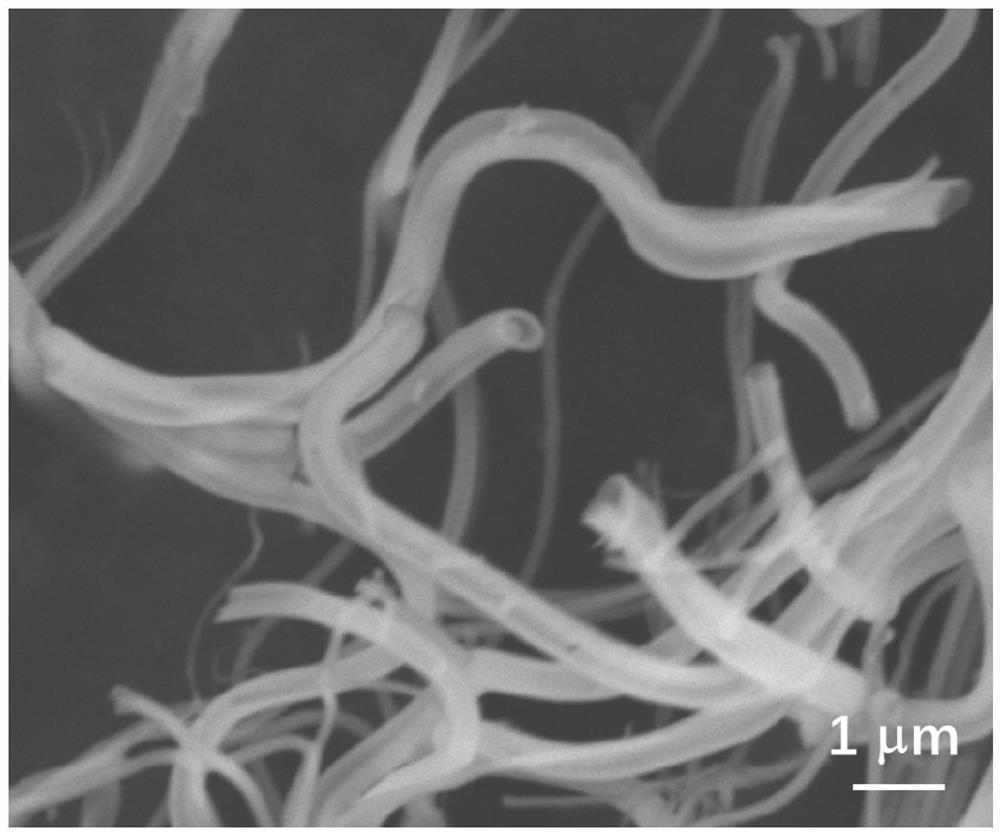

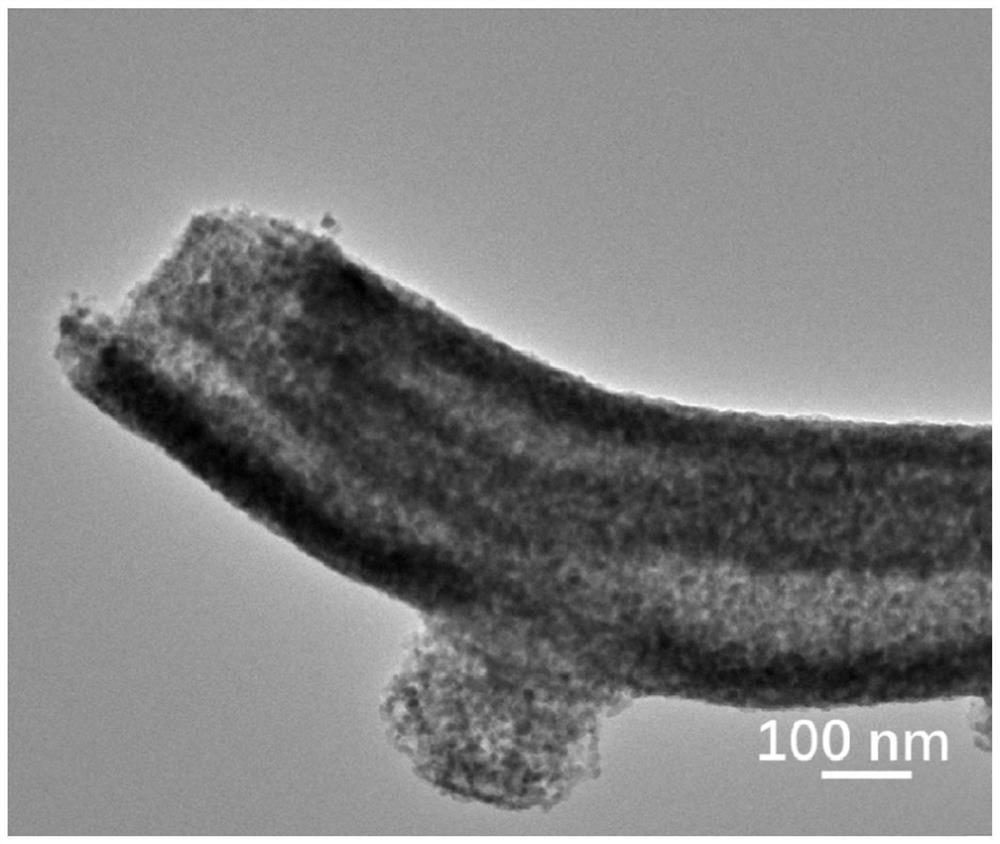

Preparation method and application of ZnMn2O4 tube-in-tube nanofibers

A nanofiber and tube-in-tube technology, applied in nanotechnology, nanotechnology, fiber processing, etc., can solve problems such as poor uniformity of tube-in-tube fibers, high equipment requirements, and difficult adjustment of coaxial spinning parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] A ZnMn 2 o 4 A method for preparing tube-in-tube nanofibers, comprising the steps of:

[0041] (1) 1 mmol of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) and 2 mmol of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O) added in the dehydrated alcohol of 5mL and the DMF of 5mL, treat Zn(CH 3 COO) 2 2H 2 O and Mn(CH 3 COO) 2 4H 2 After O was completely dissolved, 1.5 g of PVP K90 was added to the obtained metal salt solution, and after stirring at room temperature for 10 h, a light caramel-colored viscous solution was obtained, namely the spinning solution.

[0042] (2) Put the spinning solution prepared in step (1) into a 10mL syringe, set the distance between positive and negative electrodes to 15cm, set the upper limit of humidity to 50%, and set the injection speed to 0.06mm min -1 . Positive high voltage 12kV, negative high voltage 5kV. The spinning temperature was set to 40°C, and the fiber membrane was made by single nozzle electrospinning meth...

no. 2 example

[0046] A ZnMn 2 o 4 A method for preparing tube-in-tube nanofibers, comprising the steps of:

[0047] (1) 1 mmol of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) and 2 mmol of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O) added in the dehydrated alcohol of 7mL and the DMF of 3mL, treat Zn(CH 3 COO) 2 2H 2 O and Mn(CH 3 COO) 2 4H 2 After O was completely dissolved, 1.2 g of PVP K90 was added to the obtained metal salt solution, and after stirring at room temperature for 10 h, a light caramel-colored viscous solution was obtained, namely the spinning solution.

[0048] (2) Put the spinning solution prepared in step (1) into a 10mL syringe, set the distance between positive and negative electrodes to 15cm, set the upper limit of humidity to 50%, and set the injection speed to 0.06mm min -1 . Positive high voltage 12kV, negative high voltage 5kV. The spinning temperature was set to 30°C, and the fiber membrane was made by single-nozzle electrospinning meth...

no. 3 example

[0058] A ZnMn 2 o 4 A method for preparing tube-in-tube nanofibers, comprising the steps of:

[0059] (1) 1 mmol of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) and 2 mmol of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O) added to 10mL of dehydrated ethanol, treat Zn(CH 3 COO) 2 2H 2 O and Mn(CH 3 COO) 2 2H 2 After O was completely dissolved, 1.0 g of PVP K90 was added to the obtained metal salt solution, and after stirring at room temperature for 10 h, a light caramel-colored viscous solution was obtained, namely the spinning solution.

[0060] (2) Put the spinning solution prepared in step (1) into a 10mL syringe, set the distance between positive and negative electrodes to 15cm, set the upper limit of humidity to 50%, and set the injection speed to 0.1mm min -1 . Positive high voltage 10kV, negative high voltage 5kV. The spinning temperature was set at 25°C, and the fiber membrane was made by single-nozzle electrospinning.

[0061] (3) Dry the fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com