MXene-based electrothermal ink and preparation method and application thereof

An electric heating ink and electric heating technology, which is applied in the fields of ink, application, household appliances, etc., can solve the problems of unstable electric heating performance of carbon-based ink, high price, and difficult preparation of polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

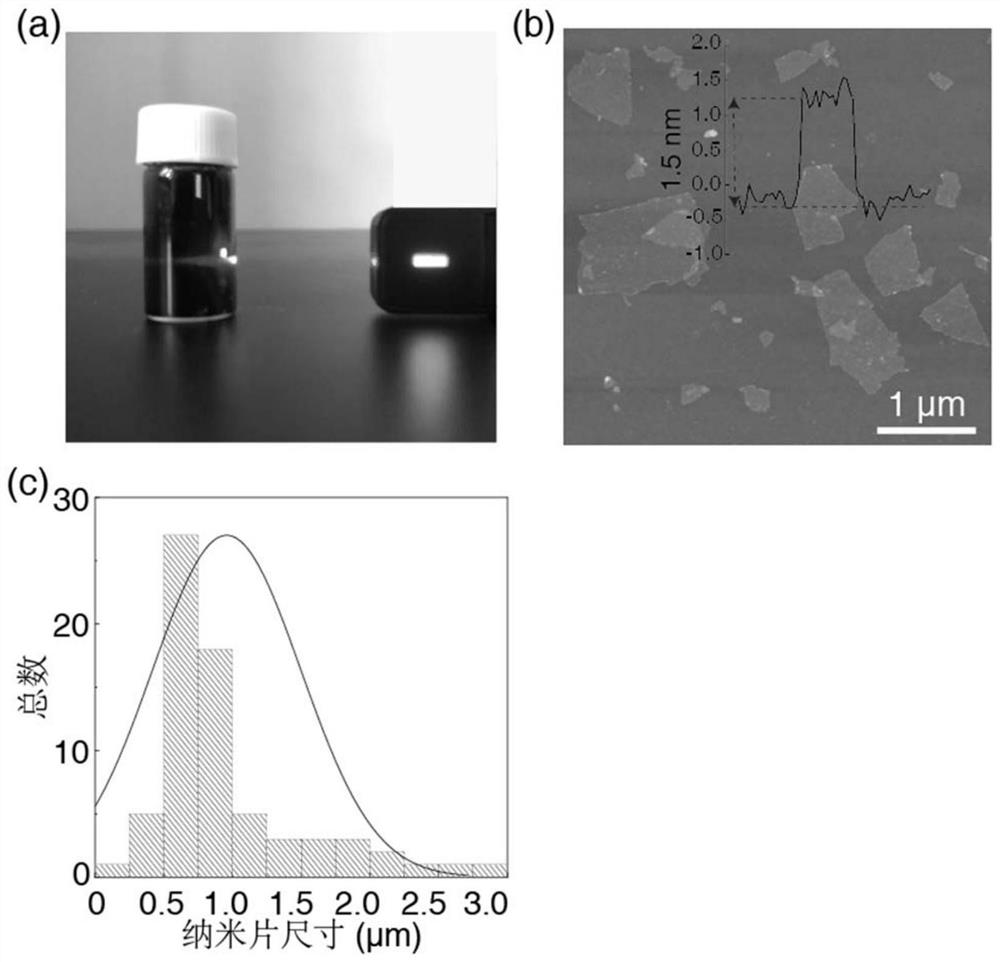

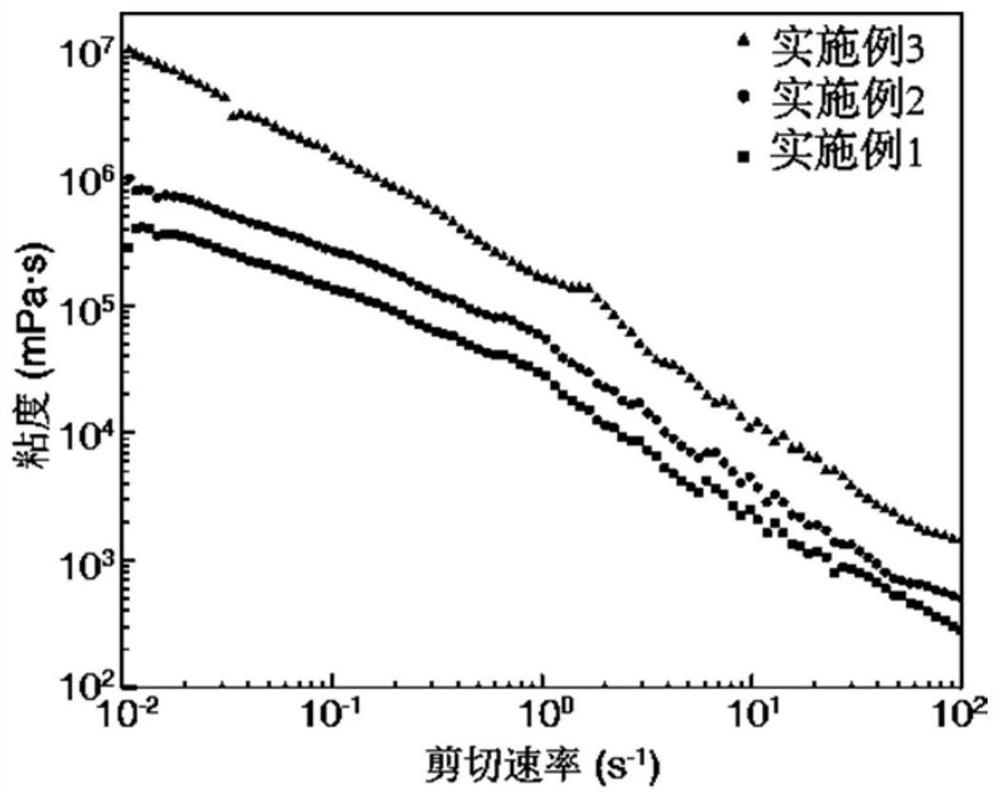

[0037] Provide a MXene-based electrothermal ink, including MXene (Ti 3 C 2 T x ) nanosheets (the particle diameter of the lateral dimension is 0.5-2.5 microns, and the sheet thickness is 1-2 nanometers), xanthan gum and water, wherein the mass fraction of MXene is 13.04%, and the mass ratio of MXene to xanthan gum is 150 :8.

[0038] Provide a kind of preparation method of above-mentioned MXene-based electrothermal ink, comprise the following steps:

[0039] 1) 1.0g precursor powder (Ti 3 AlC 2 ) was placed in a mixed solution of 20mL 9mol / L concentrated hydrochloric acid and 1.98g lithium fluoride powder for etching. After etching for a period of time, the acidic substances contained in the solution were removed by centrifugation, and then the centrifugation was continued to obtain a large amount of hydrophilic groups on the surface. Agglomerated MXene nanosheet aqueous dispersion;

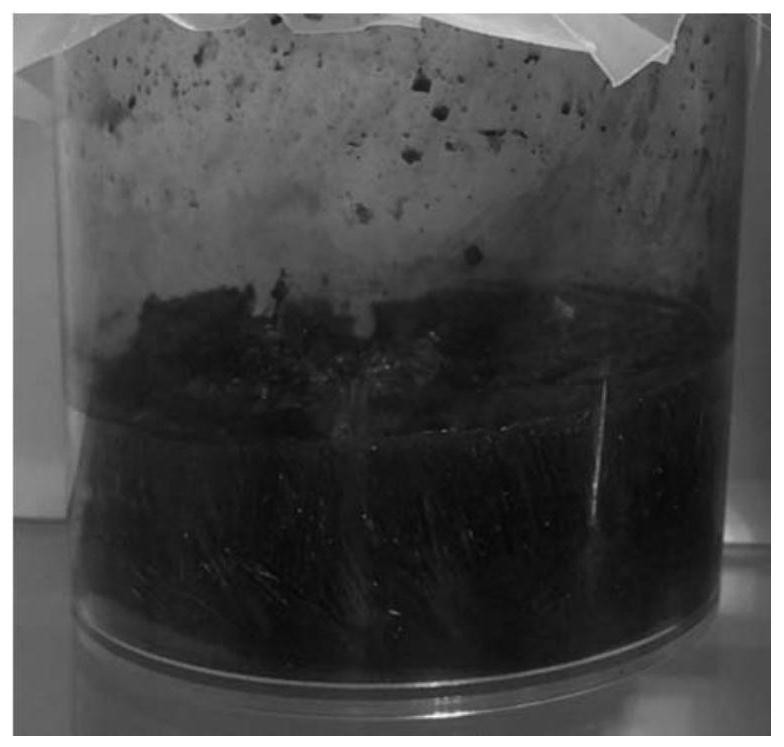

[0040] 2) The MXene suspension obtained in step 1) is frozen into ice cubes in freeze d...

Embodiment 2

[0046] Provide a MXene-based electrothermal ink, including MXene (Ti 3 C 2 T x ) nanosheets (the particle diameter of the transverse dimension is 0.5-2.5 microns, and the sheet thickness is 1-2 nanometers), xanthan gum and water, wherein the mass fraction of MXene is 16.7%, and the ratio of MXene to xanthan gum is 200: 4.

[0047] Provide a kind of preparation method of above-mentioned MXene-based electrothermal ink, comprise the following steps:

[0048] 1) 1.0g precursor powder (Ti 3 AlC 2 ) was placed in a mixed solution of 20mL 9mol / L concentrated hydrochloric acid and 1.98g lithium fluoride powder for etching. After etching for a period of time, the acidic substances contained in the solution were removed by centrifugation, and then the centrifugation was continued to obtain a large amount of hydrophilic groups on the surface. Agglomerated MXene nanosheet aqueous dispersion;

[0049] 2) The MXene suspension obtained in step 1) is frozen into ice cubes in freeze dryi...

Embodiment 3

[0055] Provide a MXene-based electrothermal ink, including MXene (Ti 3 C 2 T x ) nanosheets (the particle diameter of the lateral dimension is 0.5-2.5 microns, and the sheet thickness is 1-2 nanometers), xanthan gum and water, where the mass fraction of MXene in the bonding substrate is 21.94%, MXene and xanthan The concentration ratio of glue is 280:2.

[0056] Provide a kind of preparation method of above-mentioned MXene-based electrothermal ink, comprise the following steps:

[0057] 1) 1.0g precursor powder (Ti 3 AlC 2 ) was placed in a mixed solution of 20mL 9mol / L concentrated hydrochloric acid and 1.98g lithium fluoride powder for etching. After etching for a period of time, the acidic substances contained in the solution were removed by centrifugation, and then the centrifugation was continued to obtain a large amount of hydrophilic groups on the surface. Agglomerated MXene nanosheet aqueous dispersion;

[0058] 2) The MXene suspension obtained in step 1) is froz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com