A kind of self-healing asphalt material and its preparation method and application

A kind of asphalt material, self-healing technology, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of self-repair, large diameter of metal conductive phase, unfavorable engineering needs, etc., to increase self-healing Combined performance, improvement of road performance, reduction of modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In one embodiment of the present invention, a method for preparing the above self-healing asphalt material is provided, and the preparation method includes the following steps:

[0039] (a 1 ) adding carbon nanotubes and graphene into the molten pitch, stirring manually, until carbon nanotubes and graphene completely enter the matrix;

[0040] (a 2 ) adopts the method of high-speed shearing to disperse carbon nanotubes and graphene, so that carbon nanotubes and graphene are fully dispersed in the pitch;

[0041] (a 3 ) adding molten rubber to the mixture obtained in step (2), stirring mechanically, and heating at constant temperature during the mixing process, that is, the self-healing asphalt material is prepared.

[0042] Alternatively, the preparation method comprises the following steps:

[0043] (b 1) disperse carbon nanotubes and graphene in molten rubber, and obtain carbon nanotube / graphene / rubber composite material by extruding;

[0044] (b 2 ) adopts the...

Embodiment 1

[0054] (1) take 1g CNT and 1g graphene and add in 190g molten matrix pitch, carry out manual stirring with glass rod, until carbon nanotube completely enters pitch matrix;

[0055] (2) further adopt the method of high-speed shearing to disperse CNT and graphene, and carry out high-speed shearing for 50 minutes at a speed of 5000rpm;

[0056] (3) Finally, 8 g of molten rubber powder was added to the mixture, and mixed with a mechanical stirrer at a speed of 1500 rpm for 80 minutes. During the mixing process, the temperature was set to 160 ± 1 °C and the temperature was kept constant by putting on an electric heating mantle. A self-healing asphalt material based on carbon nanotube / graphene / rubber composite modification was prepared.

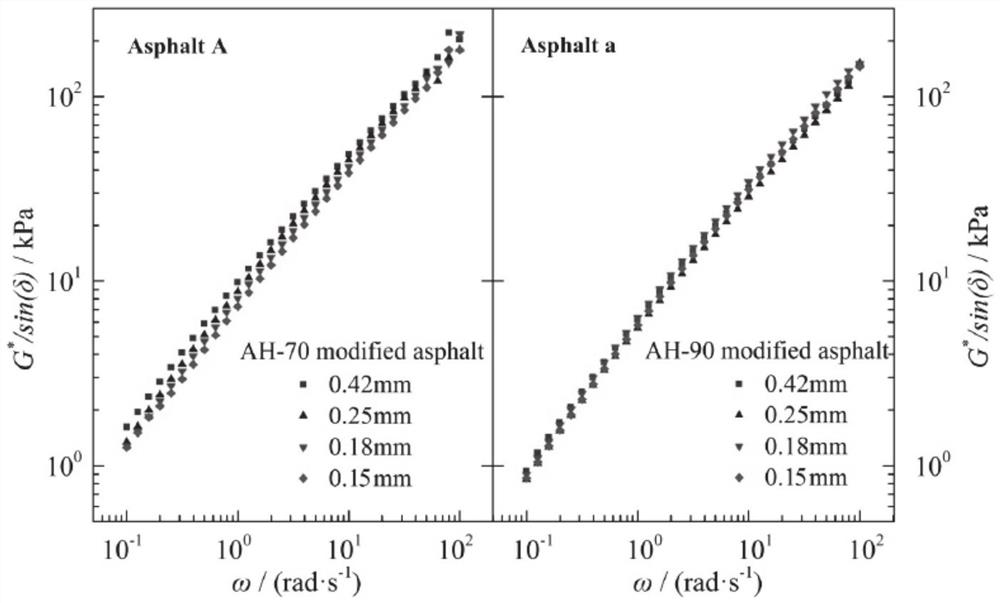

[0057] In this example, CNT and graphene are fully dispersed into the matrix asphalt through manual stirring and high shearing, and then molten rubber is added to disperse into the aforementioned mixture. The mass ratio of carbon nanotubes, graphe...

Embodiment 2

[0059] (1) Disperse 2.5g of CNT and 2.5g of graphene in 15g of molten rubber first, and disperse CNT and graphene in the rubber by extrusion to prepare a carbon nanotube / graphene / rubber composite material.

[0060] (2) Disperse the prepared 20g carbon nanotube / graphene / rubber composite material in 180g molten pitch, carry out high-speed shearing at a speed of 6000rpm for 60 minutes, and then use a mechanical stirrer to mix at a speed of 2000rpm for 100 minutes. During the process, the temperature was set at 160±1°C and kept constant by putting on an electric heating mantle. A self-healing asphalt material based on carbon nanotube / graphene / rubber composite modification was prepared.

[0061] In this example, CNT and graphene are fully dispersed into the rubber matrix by extrusion and dispersion, and then the prepared carbon nanotube / graphene / rubber composite material is added into molten asphalt, and dispersed by high-speed shearing, so that the The mass ratio of carbon nanotu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com