Environment-friendly, low-cost and high-performance railway brake pipe

A technology for brake pipes and railways, which is applied in the direction of tubular articles, the arrangement of pipes, synthetic resin layered products, etc., can solve the problems of high temperature drying tunnel, unenvironmental protection and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

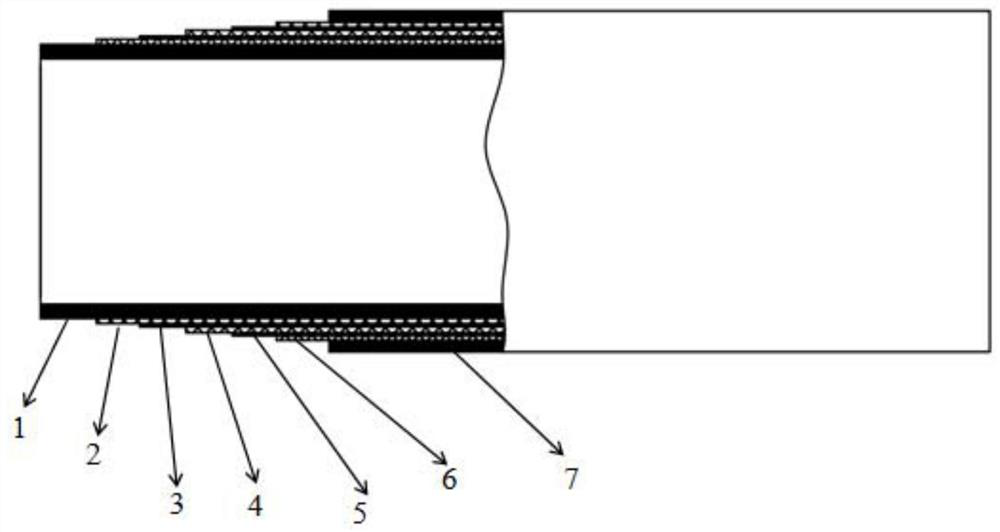

Image

Examples

Embodiment 1

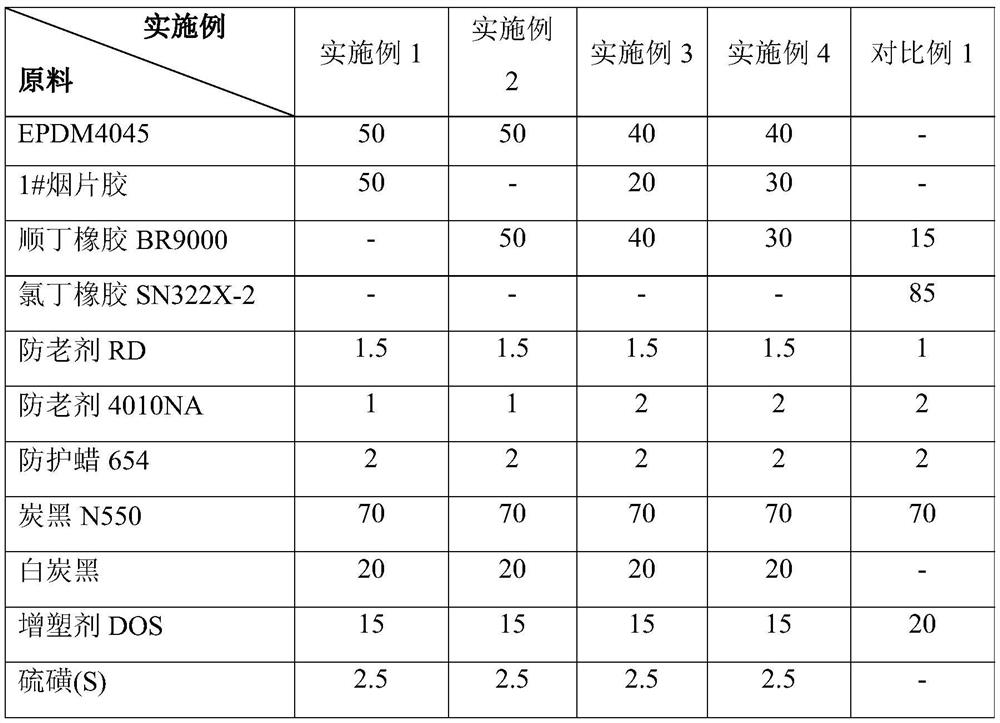

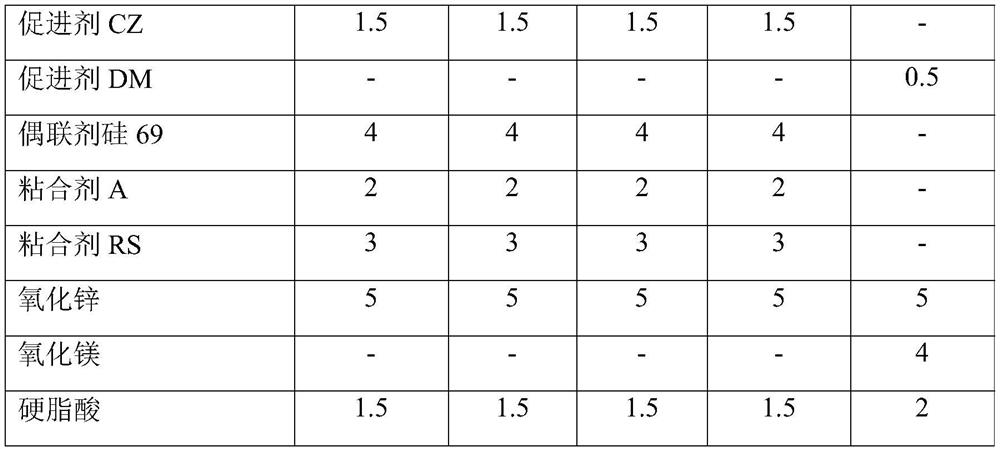

[0035] The raw materials and parts by weight of the sizing material in this embodiment are as shown in Table 1, and are prepared by the following method:

[0036] Step (1), cooling the internal mixer with water, controlling the temperature of the working room of the internal mixer to not exceed 50°C, adding base material, anti-aging agent RD, anti-aging agent 4010NA, protective wax 654, zinc oxide, stearic acid, white carbon black , binder RS, coupling agent silicon 69, knead for 30-60 seconds;

[0037] Step (2), adding plasticizer DOS and carbon black N550, mixing for 3 to 5 minutes;

[0038] Step (3), add vulcanizing agent (sulfur S), accelerator CZ, binder A, mix, and discharge the rubber compound after the temperature reaches 110°C;

[0039] Step (4), move the sizing material to an open mill for thinning out the sheet, and cool to room temperature.

Embodiment 2

[0041] The raw materials and consumption (parts by weight) of the sizing material in this embodiment are as shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0043] The raw materials and consumption (parts by weight) of the sizing material in this embodiment are as shown in Table 1, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com