Grinding wheel for ultra-high-speed grinding

An ultra-high-speed grinding and ultra-high-speed technology, applied in the field of grinding processing, can solve the problems of grinding wheel explosion, poor anti-vibration performance, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

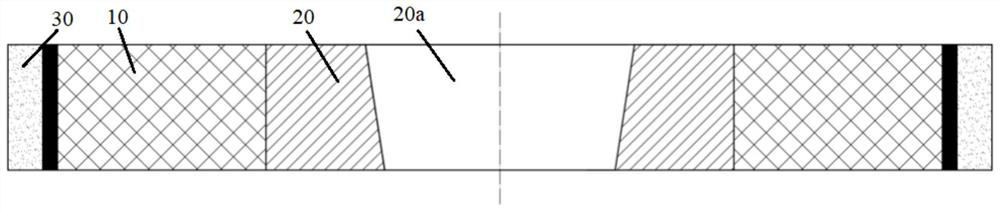

[0041] Please refer to Figure 1 to Figure 4 , this embodiment provides a grinding wheel for ultra-high-speed grinding, which can be assembled on the power spindle of processing equipment such as a grinding machine, and the power spindle can be used to drive the grinding wheel to rotate at an ultra-high speed in a controlled manner, thereby completing the grinding process of the workpiece to be processed ; Among them, ultra-high speed usually refers to the linear speed of the grinding wheel ≥ 150 m / s; the grinding wheel includes a grinding wheel base, an abrasive layer 30, a main shaft link 40 and a fastener 50, and the grinding wheel base includes a carbon fiber base 10 and a metal base 20; the following Explain separately.

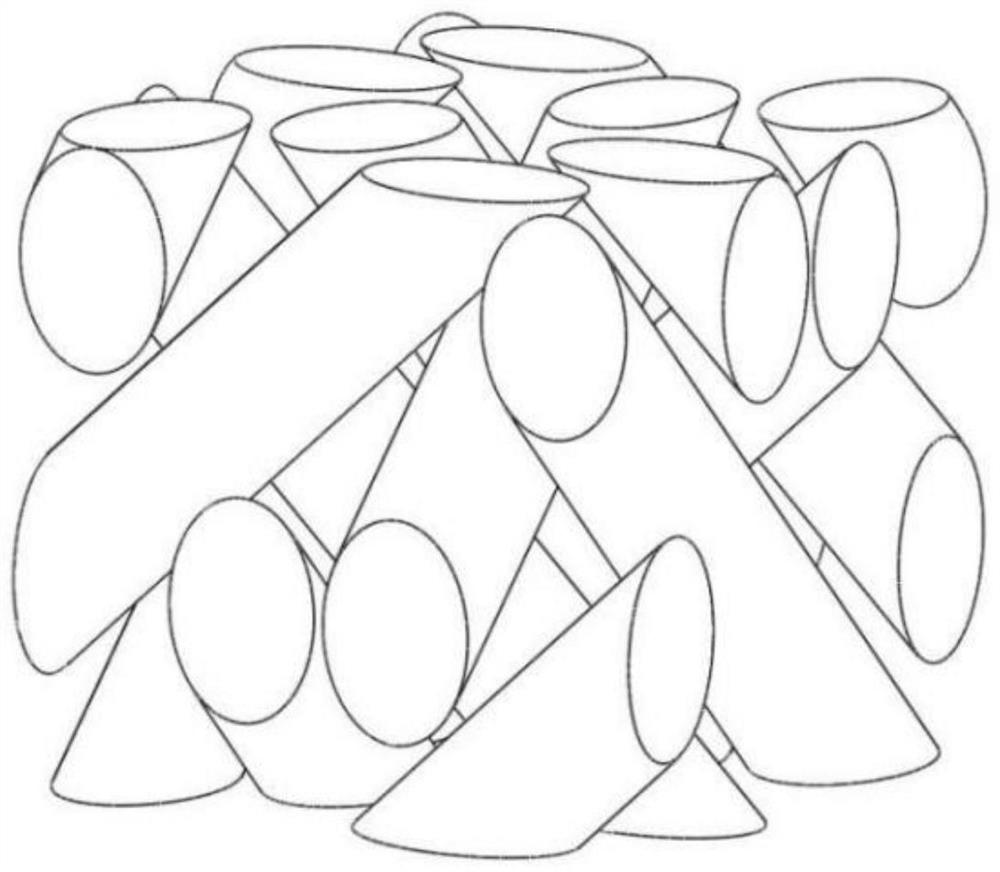

[0042] see Figure 1 to Figure 4 , the carbon fiber matrix 10 is a ring-shaped structure as a whole, mainly made of carbon fiber reinforced composite material (CFRP for short) using a three-dimensional weaving process. The three-dimensional weaving proc...

Embodiment 2

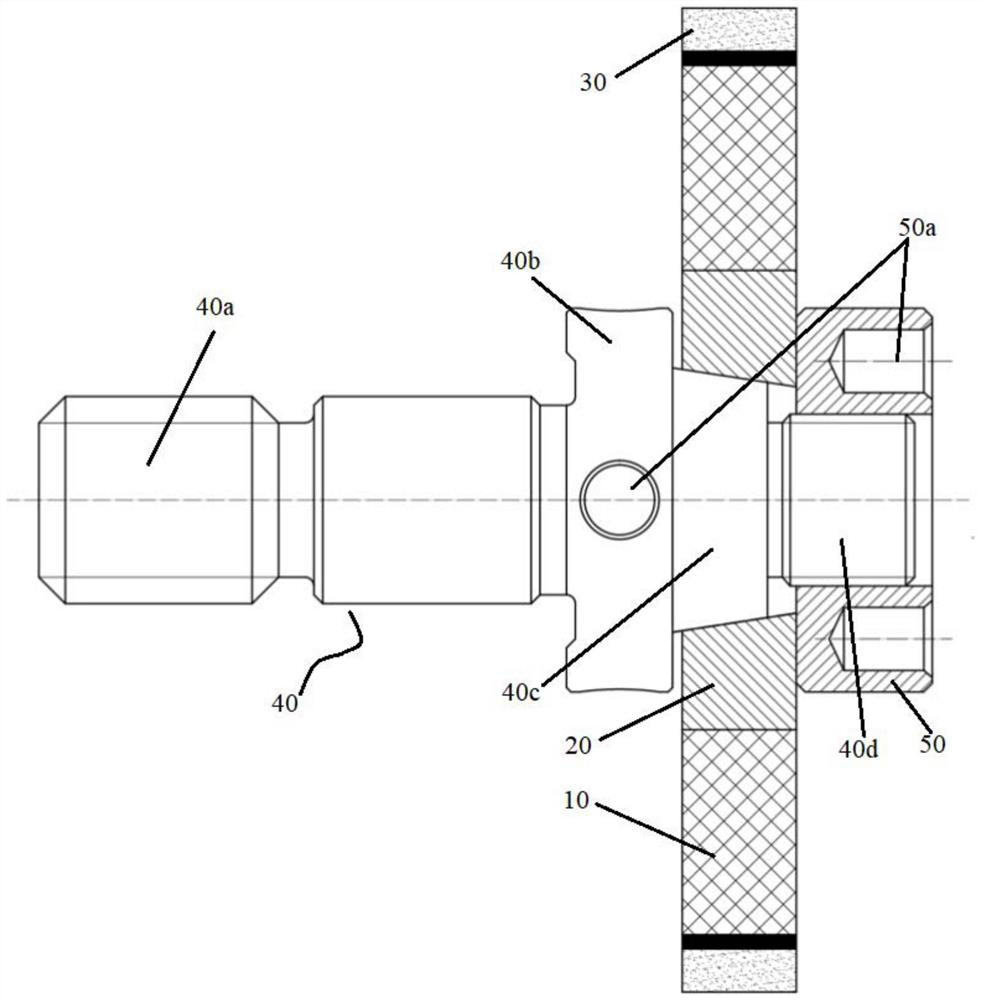

[0052] see Figure 3 to Figure 6 and combine figure 1 and figure 2 The difference between the grinding wheel for ultra-high-speed grinding provided in this embodiment and the first embodiment lies in that the structure of the main shaft link 40, the fastener 50 and the metal base 20 and the combination relationship between them are different.

[0053] see Figure 5 and Figure 6 , the main shaft link 40 can be divided into three functional structural sections such as the main shaft connecting section 40a, the flange limiting section 40b and the positioning boss section 40c along the axial direction; the main shaft connecting section 40a can be connected with the The power spindle is detachably coaxially fixedly connected, and the metal base 20 is provided with a circular through hole 20b penetrating in the axial direction and several first countersink holes 20c, and several first countersink holes 20c surround the circular through hole 20b are evenly distributed; at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com