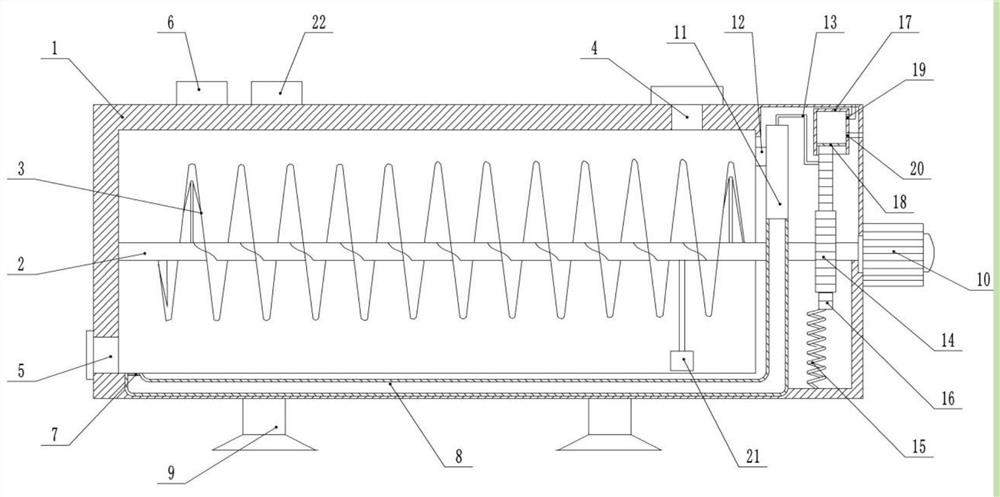

Feed stirring device with cleaning function

A feed mixing and functional technology, which is applied to mixers with rotating stirring devices, feed, mixer accessories, etc., can solve problems such as insufficient feed mixing, uneven feed mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

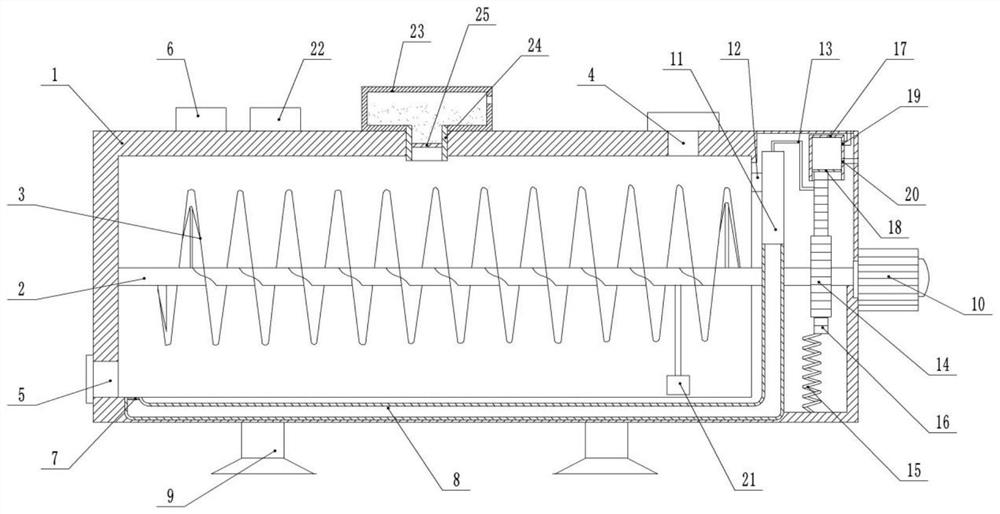

Embodiment 2

[0030] Compared with Example 1, this example differs in that, as figure 2 and image 3 shown, also includes:

[0031] The destination obtaining module is used to obtain the expected delivery address of this batch of feed; (specifically, in this embodiment, a smart phone is used to obtain enterprise ERP information)

[0032] The itinerary estimation module is used to calculate the difference time according to the current time and the estimated delivery address; time estimate, and then calculate the difference time based on the current time)

[0033] The bacterial liquid inoculation box 23, the bacterial liquid inoculation box 23 is fixed on the top of the cylinder body 1, the bacterial liquid inoculation box 23 is loaded with the bacterial liquid, and the bacterial species added in the bacterial liquid are Clostridium butyricum or Bacillus subtilis, Clostridium butyricum Bacteria, also known as butyric acid bacteria, Clostridium butyricum, butyric acid bacteria. The protea...

Embodiment 3

[0039] Compared with Example 1, this example differs in that, as Figure 4 and Figure 5 shown, also includes:

[0040] Acquisition module, for acquisition module is used for collecting every day hen house data, and hen house data comprises the weight of hen house temperature and feed trough; And hen house data is sent to store in the storage module; (specifically, in this embodiment Place a weighing scale at the bottom of the feed trough. The weighing scale model is TCS-AE / AC, and the weighing range is 0-75KG. The weighing scale measures once at 8 o'clock in the morning and once at 20:00 in the evening, using a temperature detector To detect the temperature of the chicken house, the temperature detector is a neutral X23 temperature detector, and the temperature detector measures once every hour. The weighing scale data and temperature detector data are uploaded to the enterprise ERP system through the network.)

[0041] The feed estimation module is used to obtain the daily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com