Red phosphor and method for producing same

A technology of red fluorescence and manufacturing method, which is applied in the field of red phosphor, and can solve the problems of particle surface blackening, durability reduction, optical characteristics reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

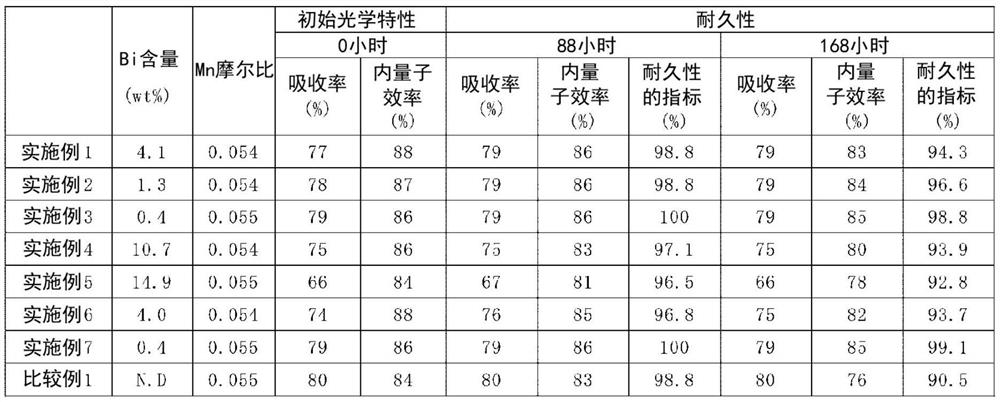

Examples

Embodiment 1

[0095] Bismuth fluoride (BiF 3 ) 0.15 g was added to 16.6 ml of hydrofluoric acid with a concentration of 43% by mass, and stirred for 5 minutes to prepare a suspension (hydrofluoric acid:bismuth=1408:1 (mixing ratio based on mass)). Next, while stirring the suspension, 5.3 g of the above-mentioned K 2 SiF 6 :Mn 4+ , and further stirred for 10 minutes.

[0096] After the stirring was complete, the suspension was allowed to stand for 10 minutes to allow the dispersed solids to settle. Then, suction filtration was performed, and the filtrate was recovered. In addition, after adding ethanol to the filtrate, suction filtration was performed again to remove the supernatant, and this operation was repeated to wash the filtrate. The filtrate after washing was recovered and dried under a nitrogen atmosphere at a drying temperature of 105° C. to evaporate ethanol. Thus, the red phosphor of Example 1 was produced.

Embodiment 2

[0098] In this example, the amount of bismuth fluoride added was changed from 0.15 g to 0.05 g (hydrofluoric acid:bismuth=423:1 (mixing ratio based on mass)). Other than that, it carried out similarly to Example 1, and produced the red phosphor of Example 2.

Embodiment 3

[0100] In this example, the amount of bismuth fluoride added was changed from 0.15 g to 0.015 g (hydrofluoric acid:bismuth=141:1 (mixing ratio based on mass)). Except for this, it carried out similarly to Example 1, and produced the red phosphor of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com