Composition for forming release layer for slit die coating, and release layer

A technology of peeling layer and composition, which is applied to the device, coating, lamination and other directions of coating liquid on the surface, can solve the problem of uneven coating, and achieve the effect of improving the yield and speeding up the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0169] In preparation of the composition for peeling layer formation of this invention, the solution of the specific copolymer (polymer) obtained by the polymerization reaction in a solvent can be used as it is. In this case, for example, in the solution of (A) component, put (B) component, further (C) component, (D) component, (E) component, etc. in the same manner as above, to make a uniform solution . At this time, for the purpose of adjusting the concentration, a solvent may be further added. In this case, the solvent used for the production|generation process of (A) component and the solvent used for concentration adjustment of the composition for peeling layer formation may be the same or different.

[0170] In addition, it is preferable to use the solution of the prepared composition for peeling layer formation after filtration using a filter or the like with a pore diameter of about 0.2 μm.

[0171] The viscosity of the composition for forming a peeling layer of the ...

Embodiment

[0188] Synthesis examples, preparation examples, examples and comparative examples are listed below to describe the present invention in more detail, but the present invention is not limited by the following examples.

[0189] The compounds used in the following examples are as follows. Note that the vapor pressure is a value at 20°C.

[0190] PGME: Propylene glycol monomethyl ether (vapor pressure 1200Pa)

[0191] PGMEA: Propylene Glycol Monomethyl Ether Acetate (Vapor Pressure 500Pa)

[0192] EL: ethyl lactate (vapor pressure 279Pa)

[0193] GBL: γ-butyrolactone (vapor pressure 150Pa)

[0194] DEGEEA: diethylene glycol monoethyl ether acetate (vapor pressure 6Pa)

[0195] Triglyme: triethylene glycol dimethyl ether (vapor pressure 120Pa)

[0196] Diglyme: Diethylene glycol dimethyl ether (vapor pressure 330Pa)

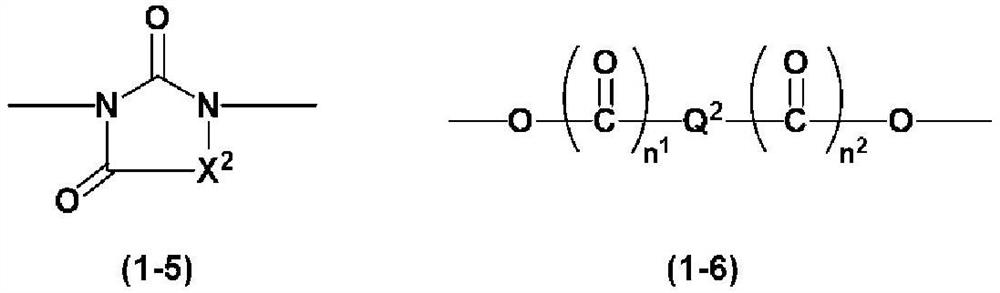

[0197] PL-LI: 1,3,4,6-Tetrakis(methoxyethyl)glycoluril (manufactured by Allnex, trade name: POWDERLINK1174)

[0198] PPTS: pyridinium p-toluenesulfonate

[0...

Synthetic example 1

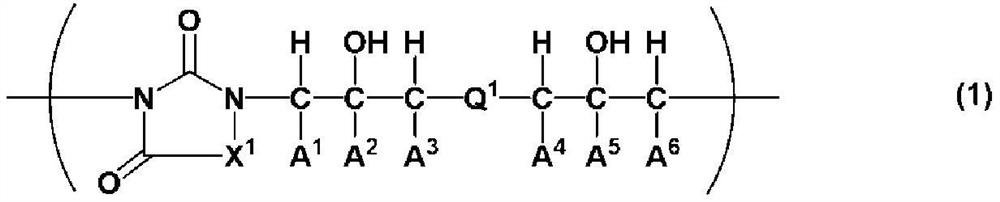

[0206] [Synthesis Example 1] Synthesis of polyurea (L1)

[0207] Dissolve 100 g of monoallyl diglycidyl isocyanurate (manufactured by Shikoku Chemical Industry Co., Ltd.), 66.4 g of 5,5-diethylbarbituric acid, and 4.1 g of benzyltriethylammonium chloride After 682 g of PGME, it was made to react at 130 degreeC for 24 hours, and the solution (20 mass % of solid content concentration) containing polyurea (L1) was obtained. Results of GPC analysis: Mw of the obtained polyurea (L1) was 8,000, and Mw / Mn was 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com