Preparation method of lithium/potassium ion battery negative electrode material

A technology of battery negative electrode and negative electrode material, applied in electrode manufacturing, battery electrode, carbon preparation/purification, etc., can solve the problems of no practical application research, no anthracite pyrolysis carbon material, low-cost preparation, etc., and achieve abundant reserves , good for diffusion and storage, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Anthracite pyrolysis carbon material I

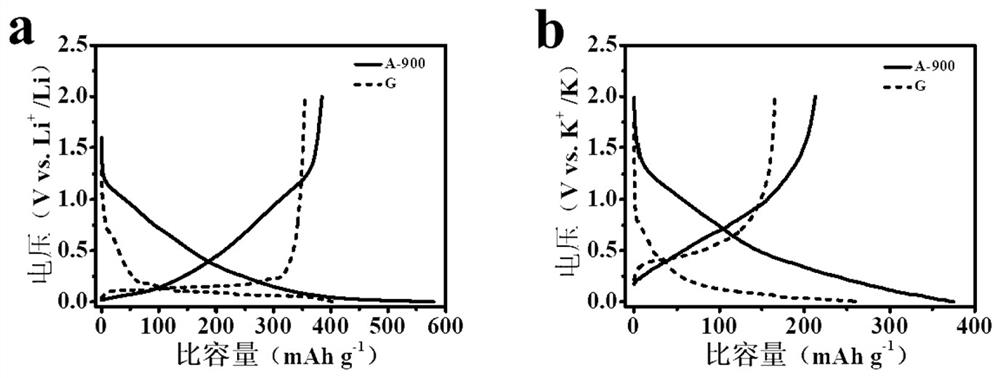

[0031] Pulverize block anthracite to obtain anthracite powder with a specific surface area of 1-10 m 2 g -1 , with an average pore size of 1-10 nm, placed in an argon atmosphere, heat-treated at 900 °C for 2 h, and cooled to room temperature to obtain anthracite pyrolytic carbon material A-900. figure 1 (a) Scanning electron micrograph and (b) high-resolution transmission electron micrograph of the anthracite pyrolysis carbon material prepared for , it can be seen from the figure that the anthracite pyrolysis carbon material presents a block shape with smooth surface and irregular shape , its microstructure presents a disordered / ordered hybrid structure, which is significantly different from the long-range ordered structure of graphite. In addition, the selected area electron diffraction pattern of the anthracite pyrolysis carbon material also shows unclear diffraction rings, which also proves that it has a typical...

Embodiment 2

[0032] Example 2 Anthracite pyrolysis carbon material II

[0033] Pulverize block anthracite to obtain anthracite powder with a specific surface area of 1-10 m 2 g -1 , with an average pore size of 1-10 nm, placed in an argon atmosphere, heat-treated at 700 °C for 2 h, and cooled to room temperature to obtain anthracite pyrolytic carbon material A-700. The test conditions of the anthracite pyrolytic carbon material are as described in Example 1, and the results show that in the lithium-ion half-cell, the anthracite pyrolytic carbon material can be tested at 100 mA g -1 Under the current density, the reversible capacity after 60 cycles is 317.0 mAh g -1 . In a potassium-ion half-cell, the anthracite pyrolytic carbon material operates at 100 mA g -1 Under the current density, the reversible capacity after 60 cycles is 137.4mAh g -1 . The experimental results show that the anthracite pyrocarbon with disordered / ordered mixed carbon layer structure is mainly stored in defe...

Embodiment 3

[0034] Example 3 Anthracite pyrolysis carbon material III

[0035] Pulverize block anthracite to obtain anthracite powder with a specific surface area of 1-10 m 2 g -1 , with an average pore size of 1-10 nm, placed in an argon atmosphere, heat-treated at 1100 °C for 2 h, and cooled to room temperature to obtain anthracite pyrolytic carbon material A-1100. The test conditions of the anthracite pyrolytic carbon material are as described in Example 1, and the results show that in the lithium-ion half-cell, the anthracite pyrolytic carbon material can be tested at 100 mA g -1 Under the current density, the reversible capacity after 60 cycles is 319.3 mAh g -1 . In a potassium-ion half-cell, the anthracite pyrolytic carbon material operates at 100 mA g -1 Under the current density, the reversible capacity after 60 cycles is 118.5mAh g -1 . As the pyrolysis temperature increases, the defect degree of anthracite pyrolysis carbon material decreases, and the lithium storage an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com