An electrocatalytic reduction of CO 2 Cu-mof material and preparation method thereof

An electrocatalysis, CO2 technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of low selectivity of catalytic products, low yield, poor catalyst stability, etc., to improve catalytic rate and selectivity, prolong Durability, the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

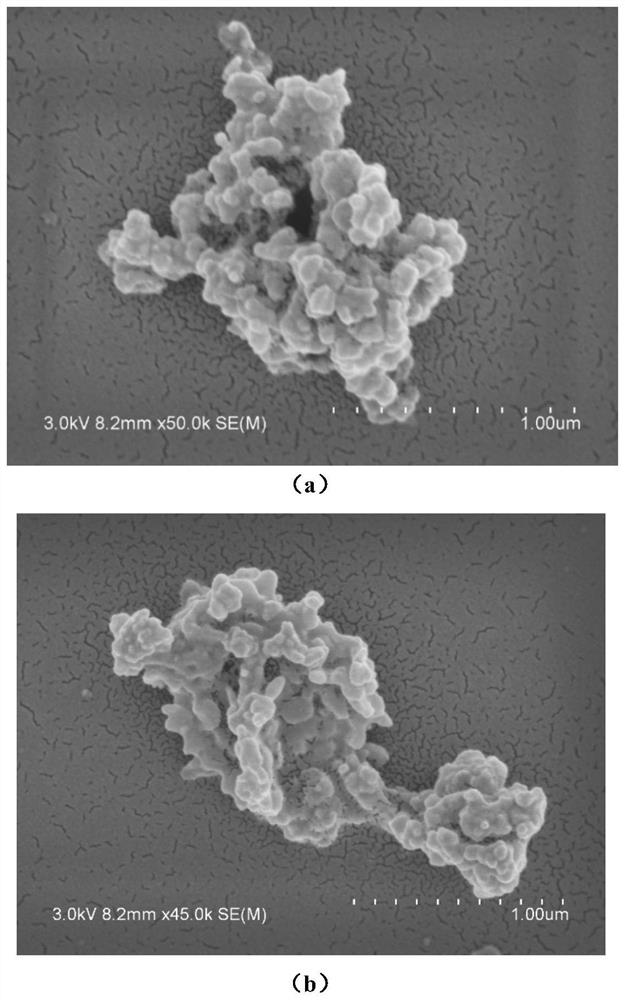

Image

Examples

Embodiment 1

[0027] (1) Take 5g of 3,4,9,10-perylenetetraic acid dianhydride, add it to 100mL N,N-dimethylformamide solution, stir and then add dropwise 15mL 1-(3-aminopropyl)imidazole , heated to 140°C, condensed and refluxed, stirred at a constant temperature in an inert gas environment for 12 hours, filtered and washed with tetrahydrofuran to remove 1-(3-aminopropyl)imidazole remaining on the surface, put it into a vacuum oven, raised to 60°C, and kept at a constant temperature Drying for 8 hours to remove residual THF gave the PDI product as a red powder.

[0028] (2) Get 4g of the PDI prepared in step (1), add 300mL of chloroform solution, seal and sonicate for 0.5h, obtain the chloroform supersaturated solution of PDI, filter with a sand core filter, remove the filter cake, collect The filtrate with fluorescent color is a chloroform saturated solution of PDI;

[0029] Dissolve an appropriate amount of copper chloride dihydrate in methanol to prepare a methanol solution of copper chl...

Embodiment 2

[0035](1) Take 3g of 3,4,9,10-perylenetetraic acid dianhydride, add it to 100mL N,N-dimethylformamide solution, stir and then add 10mL 1-(3-aminopropyl)imidazole dropwise, Heat up to 140°C, condense and reflux, stir at constant temperature for 12 hours in an inert gas environment, filter and wash with tetrahydrofuran to remove 1-(3-aminopropyl)imidazole remaining on the surface, put it in a vacuum oven, heat up to 60°C, and dry at constant temperature 8 hours to remove residual THF to give the PDI product as a red powder.

[0036] (2) Get 2g of the PDI prepared in step (1), add 150mL of chloroform solution, seal and sonicate for 0.5h, obtain the chloroform supersaturated solution of PDI, filter with a sand core filter, remove the filter cake, and collect The filtrate with fluorescent color is a chloroform saturated solution of PDI;

[0037] Dissolve an appropriate amount of copper chloride dihydrate in methanol to prepare a methanol solution of copper chloride dihydrate with ...

Embodiment 3

[0041] (1) Take 4g of 3,4,9,10-perylenetetraic acid dianhydride, add it to 50mL N,N-dimethylformamide solution, stir and then add dropwise 10mL 1-(3-aminopropyl)imidazole , heated to 120°C, condensed and refluxed, stirred at a constant temperature in an inert gas environment for 16 hours, filtered and washed with tetrahydrofuran to remove 1-(3-aminopropyl)imidazole remaining on the surface, put it into a vacuum oven, raised to 80°C, and kept at a constant temperature Drying for 4 hours to remove residual THF gave the PDI product as a red powder.

[0042] (2) Get 4g of the PDI prepared in step (1), add 300mL of chloroform solution, seal and sonicate for 1h, obtain the chloroform supersaturated solution of PDI, filter with a sand core filter, remove the filter cake, and collect The filtrate of fluorescent color is a chloroform saturated solution of PDI;

[0043] Dissolve an appropriate amount of copper chloride dihydrate in methanol to form a methanol solution of copper chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com