Foam separation method for concentrating and separating rosmarinic acid in perilla leaves

A foam separation method and foam separation technology, applied in the field of rosmarinic acid, can solve the problems of concentration effect and complex operation process in easily polluted environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

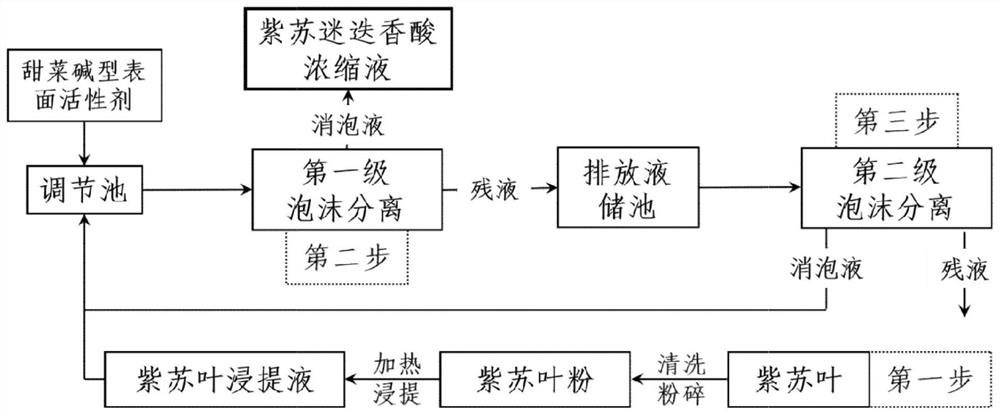

[0085] Embodiment 1: the preparation of perilla rosmarinic acid concentrate

[0086] The first step, the preparation of perilla leaf extract

[0087] The dried perilla leaves were pulverized by a high-speed pulverizer and passed through an 80-mesh sieve to obtain perilla leaf powder; water was added to the perilla leaf powder according to a material-liquid ratio of 1:100 (g / mL), and the mixture was heated at room temperature and at a speed of 500 r / mL. Stir for 0.2h at a temperature of 90°C and a rotational speed of 60r / min for 1.0h with a rotary evaporator, cool to room temperature and centrifuge at 4000r / min for 15min, take the supernatant and put it in a conditioning tank to obtain perilla Leaf extract, wherein the perilla rosmarinic acid concentration is 246.9mg / L.

[0088] The concentration of rosmarinic acid in perilla is given in "Spectrophotometric Determination of Rosmarinic Acid Content in Perilla Leaves" published by Du Guicai and other researchers on "Journal of Q...

Embodiment 2

[0094] Embodiment 2: the preparation of perilla rosmarinic acid concentrate

[0095] The first step, the preparation of perilla leaf extract

[0096] The dried perilla leaves were pulverized by a high-speed pulverizer and passed through an 80-mesh sieve to obtain perilla leaf powder; water was added to the perilla leaf powder according to a material-liquid ratio of 1:100 (g / mL), and the mixture was heated at room temperature and at a speed of 500 r / mL. Stir for 0.2h at a temperature of 90°C and a rotational speed of 60r / min for 1.0h with a rotary evaporator, cool to room temperature and centrifuge at 4000r / min for 15min, take the supernatant and put it in a conditioning tank to obtain perilla Leaf extract, wherein the perilla rosmarinic acid concentration is 246.9mg / L.

[0097] The second step, the first stage foam separation process

[0098] Add 200 mg / L of cocamidopropyl betaine to the perilla leaf extract in the adjustment tank for the first time, adjust the pH value of t...

Embodiment 3

[0102] Embodiment 3: the preparation of perilla rosmarinic acid concentrate

[0103] The first step, the preparation of perilla leaf extract

[0104] The dried perilla leaves were pulverized by a high-speed pulverizer and passed through an 80-mesh sieve to obtain perilla leaf powder; water was added to the perilla leaf powder according to a material-liquid ratio of 1:100 (g / mL), and the mixture was heated at room temperature and at a speed of 500 r / mL. Stir for 0.2h at a temperature of 90°C and a rotational speed of 60r / min for 1.0h with a rotary evaporator, cool to room temperature and centrifuge at 4000r / min for 15min, take the supernatant and put it in a conditioning tank to obtain perilla Leaf extract, wherein the perilla rosmarinic acid concentration is 246.9mg / L.

[0105] The second step, the first stage foam separation process

[0106] Add 200mg / L of BS12 to the perilla leaf extract in the adjustment tank for the first time, adjust the pH value of this mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com