Pearl antibacterial non-woven fabric medical protective mask and preparation method thereof

A pearl antibacterial and non-woven technology, applied in the field of health protection, can solve the problems of poor sealing of masks, skin allergies, respiratory system damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A method for preparing a pearl antibacterial nonwoven medical protective mask, used to prepare any of the above pearl antibacterial nonwoven medical protective masks, the preparation method comprising the following steps:

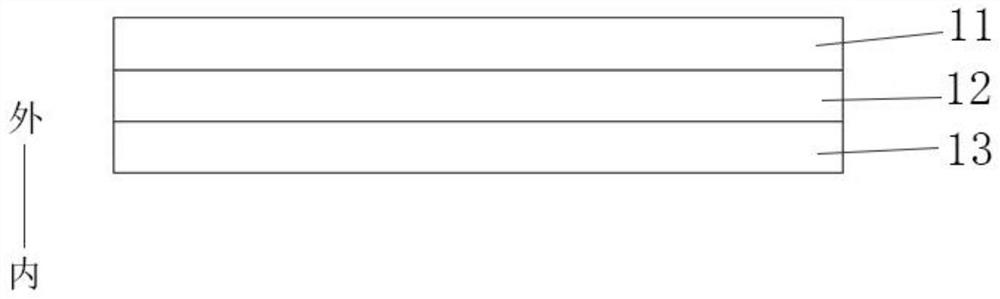

[0053] Step 1, the outer layer 11, the middle layer 12 and the inner layer 13 are transported to the conveyor in sequence through three stations;

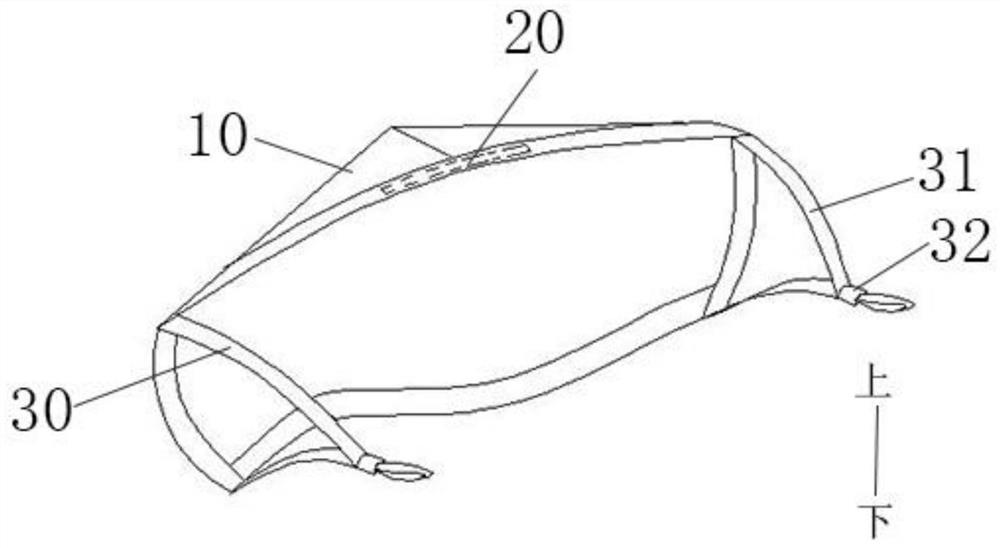

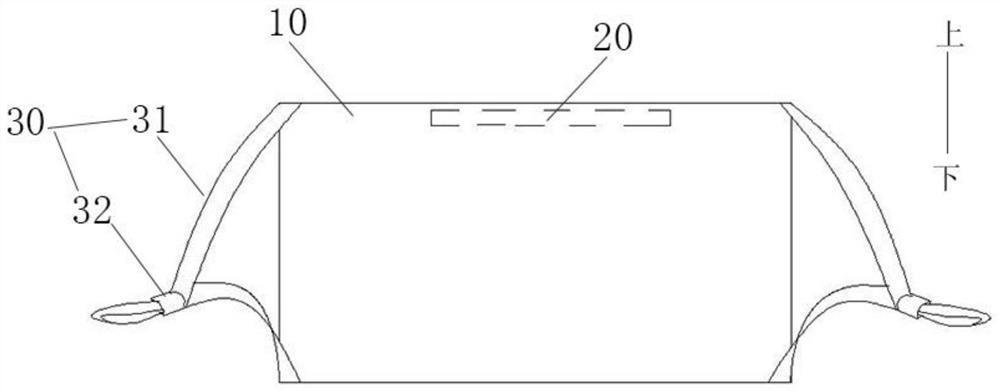

[0054] Step 2, at the moment when the outer layer 11, the middle layer 12 and the inner layer 13 are in contact, the nose clip 20 is inserted into the middle by the manipulator, and then the outer layer 11, the middle layer 12, the inner layer 13 and the nose clip 20 are sealed by an ultrasonic heat sealing device. join together;

[0055] Step 3, the product obtained in step 2 passes through the folding device and the ultrasonic heat sealing device while being conveyed, so that the mask is formed;

[0056] Step 4: Cut the formed mask, and then install the ear-hanging rope assembly 30 on both sides of the...

Embodiment 1

[0060] Prescription (comprising the following components in parts by weight):

[0061] Outer layer: 40% antibacterial fiber, 60% polypropylene fiber.

[0062] The first synthetic fiber is polypropylene fiber; the antibacterial fiber is prepared from second synthetic fiber and inorganic antibacterial powder, the second synthetic fiber is viscose fiber; the inorganic antibacterial powder is zinc oxide.

[0063] Middle layer: 20% pearl blend fiber, 80% polypropylene fiber.

[0064] Inner layer: 20% pearl blend, 80% viscose.

[0065] The third synthetic fiber is viscose fiber.

[0066] Preparation:

[0067] Step 1, the outer layer 11, the middle layer 12 and the inner layer 13 are transported to the conveyor in sequence through three stations;

[0068] Step 2, at the moment when the outer layer 11, the middle layer 12 and the inner layer 13 are in contact, the nose clip 20 is inserted into the middle by the manipulator, and then the outer layer 11, the middle layer 12, the inn...

Embodiment 2

[0072] Prescription (comprising the following components in parts by weight):

[0073] Outer layer: 30% antimicrobial fibers, 70% viscose.

[0074] The first synthetic fiber is viscose fiber; the antibacterial fiber is prepared from second synthetic fiber and inorganic antibacterial powder, the second synthetic fiber is polyester; and the inorganic antibacterial powder is copper oxide.

[0075] Middle layer: 10% pearl blended fiber, 90% polypropylene composite fiber.

[0076] Inner Layer: 20% Pearl Blend, 80% Polyester.

[0077] The third synthetic fiber is polyester.

[0078] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Airflow resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com