Preparation method of high-strength nano cellulose-nano aramid fiber composite film

A nanocellulose and composite film technology, applied in the field of nanomaterials, can solve the problems of the lack of charge repulsion of ordinary nanocellulose, the decrease of the strength of the nanoaramid film, and the difficulty in dispersing the nanoaramid fiber, so as to increase the strain, improve the toughness, and increase the stress. The effect of improving the transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

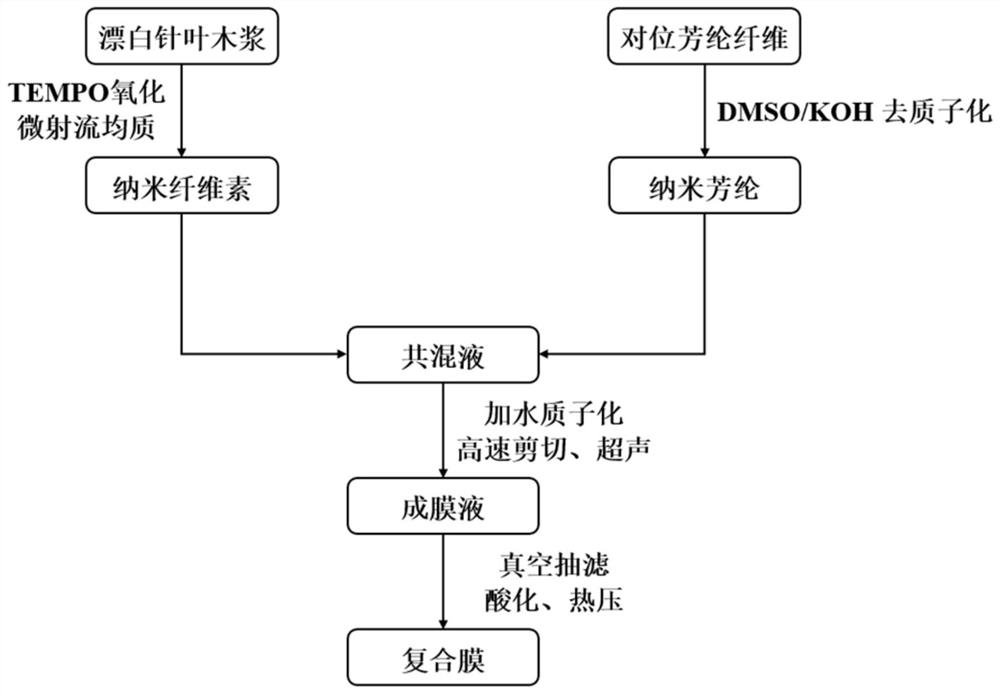

Method used

Image

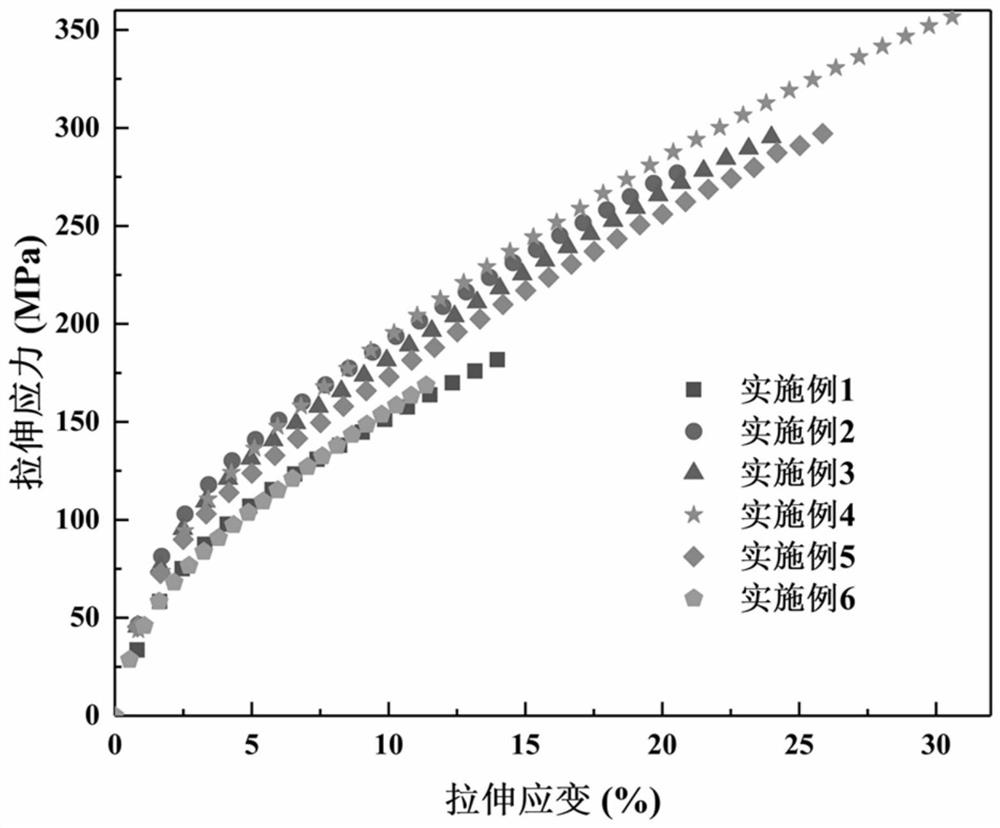

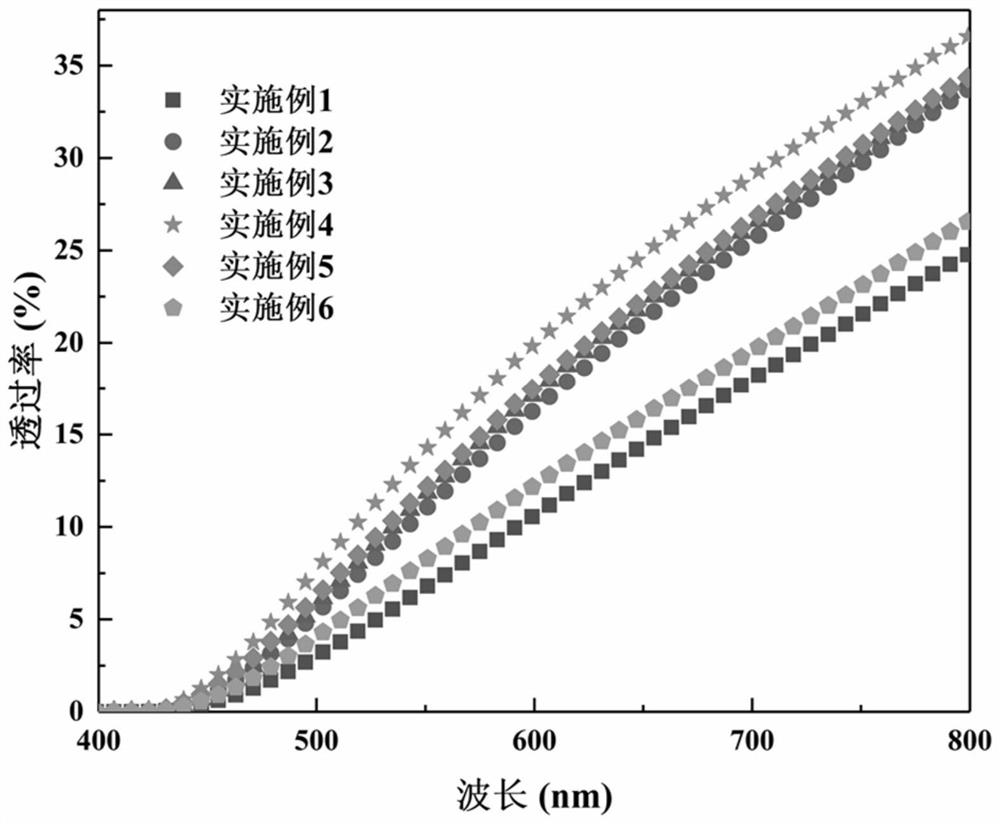

Examples

Embodiment 1

[0035] The preparation method of the pure nano-aramid film in the present embodiment, the specific preparation steps are as follows:

[0036] (1) Disperse 1 g of para-aramid chopped fibers in 500 mL of DMSO, add 1.5 g of KOH, and continue stirring for 7 days to obtain a nano-aramid dispersion with a concentration of 2 mg / L.

[0037] (2) Add 100mL DMSO to 132.47mL nano-aramid dispersion. Subsequently, 132.47 mL of deionized water was added to protonate the nano-aramid fiber, and then the solution was sheared at 40000 r / min for 5 min.

[0038] (3) The solution was ultrasonically treated at 800W for 5 minutes, and then the nano-aramid hydrogel was obtained by vacuum filtration. Add 100 mL of deionized water to the filter, filter and wash the nano-aramid hydrogel to remove residual DMSO and KOH.

[0039] (4) The nano-aramid hydrogel was hot-pressed at 80°C for 24 hours to finally obtain a nano-aramid film with a quantitative value of 60g / m 2 .

Embodiment 2

[0041] The preparation method of the high-strength nano-cellulose-nano-aramid fiber composite film in this embodiment, the specific preparation steps are as follows:

[0042] (1) Disperse 1 g of para-aramid chopped fibers in 500 mL of DMSO, add 1.5 g of KOH, and continue stirring for 7 days to obtain a nano-aramid dispersion with a concentration of 2 mg / L.

[0043] (2) Disperse 10 g of dry bleached softwood pulp in 1 L of deionized water, add 160 mg of 2,2,6,6-tetramethylpiperidine nitrogen oxide and 1 g of sodium bromide, and stir to disperse evenly. Then add 75mmol sodium hypochlorite solution to carry out TEMPO oxidation reaction, and keep the pH of the suspension stable at 10-10.5. After the reaction, the suspension was washed by centrifugal filtration until the pH of the filtrate reached neutral. The treated suspension was fibrillated using a micro-fluid homogenizer at a concentration of 0.8 wt%, using a pore size of 200 μm, and homogenized 8 times under a pressure of 138 ...

Embodiment 3

[0048] The preparation method of the high-strength nano-cellulose-nano-aramid fiber composite film in this embodiment, the specific preparation steps are as follows:

[0049] (1) Disperse 1 g of para-aramid chopped fibers in 500 mL of DMSO, add 1.5 g of KOH, and continue stirring for 7 days to obtain a nano-aramid dispersion with a concentration of 2 mg / L.

[0050] (2) Disperse 10 g of dry bleached softwood pulp in 1 L of deionized water, add 160 mg of 2,2,6,6-tetramethylpiperidine nitrogen oxide, and 1 g of sodium bromide, and stir to disperse evenly. Then add 75mmol sodium hypochlorite solution to carry out TEMPO oxidation reaction, and keep the pH of the suspension stable at 10-10.5. After the reaction, the suspension was washed by centrifugal filtration until the pH of the filtrate reached neutral. The treated suspension was fibrillated using a micro-fluid homogenizer at a concentration of 0.8 wt%, using a pore size of 200 μm, and homogenized 8 times under a pressure of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com