Polypyrrole-coated cattail wool-based ultra-light biomass porous foam as well as preparation method and application thereof

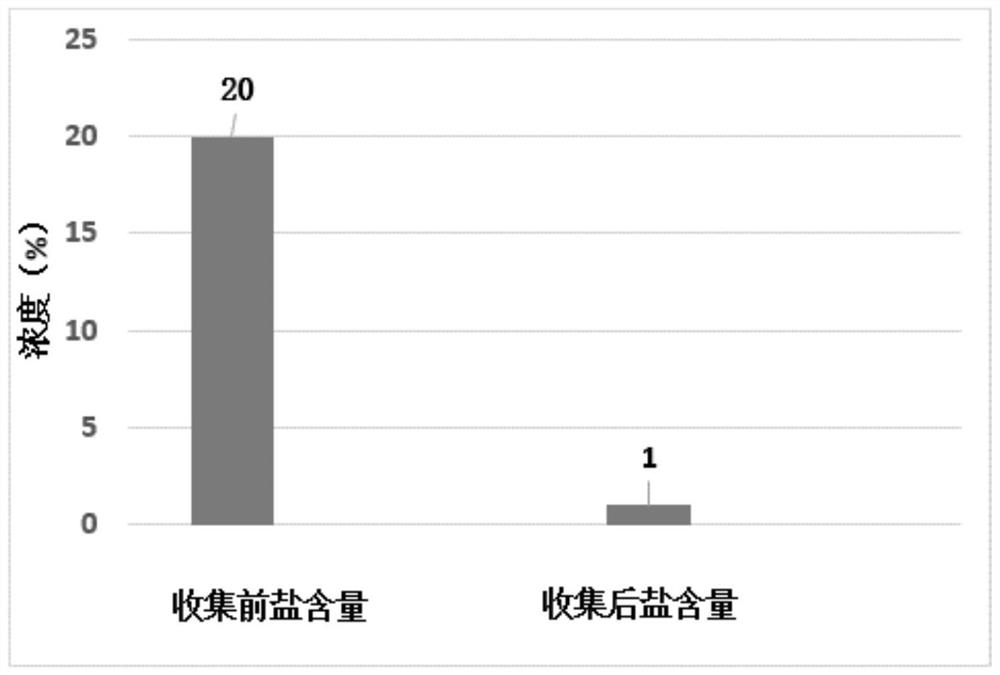

A porous foam and velvet-based technology is applied in the field of polypyrrole-coated cattail velvet-based ultra-light biomass porous foam and its preparation, which can solve the problem of poor salt resistance and evaporation efficiency of aerogel-polypyrrole photothermal conversion materials. and low energy conversion efficiency, evaporation efficiency decline and other problems, to achieve the effect of helping environmental protection and clean energy development, abundant output and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

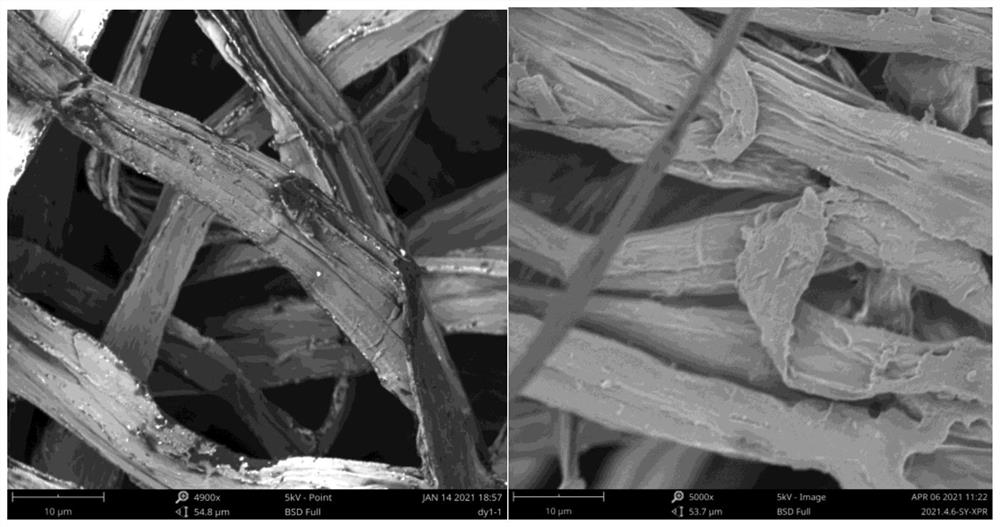

[0031] The invention provides a preparation method of polypyrrole-coated cattail velvet base ultra-light biomass porous foam, comprising the following steps:

[0032] S1. Wash the cattail velvet and place it in an alkaline solution for heating in a water bath. After fully removing impurities, it is washed, and then the washed cattail velvet is stirred at a high speed to obtain the pretreated cattail velvet;

[0033] S2, respectively prepare polyvinyl alcohol solution and tannic acid solution of predetermined mass fraction; then add the cattail velvet after the pretreatment that step S1 obtains in the polyvinyl alcohol solution, and obtain cattail velvet / polyethylene after fully stirring Alcohol mixed solution, then the tannic acid solution is added in the cattail velvet / polyvinyl alcohol mixed solution, after fully reacting, carry out freeze-drying, obtain the cattail velvet base ultra-light biomass porous foam;

[0034] S3. Prepare a mixed solution containing an oxidizing age...

Embodiment 1

[0044] This embodiment provides a preparation method of polypyrrole-coated cattail velvet-based ultra-light biomass porous foam, comprising the following steps:

[0045] S1. Take 8g of cattail velvet and wash it repeatedly with distilled water and deionized water to remove impurities. Then prepare a potassium hydroxide solution with a concentration of 5wt% as an alkaline solution, put the washed cattail hair into the alkaline solution, and heat it in a water bath at 60°C for 4 hours to fully dissolve impurities such as hemicellulose and gum in the cattail hair Afterwards, it is washed with distilled water, and then the washed cattail velvet is stirred at a speed of 12000r / min for 8min with a high-speed mixer to shorten the cattail velvet and obtain the pretreated cattail velvet.

[0046] S2. Add 5g of polyvinyl alcohol into water, stir in an oil bath at 90°C for 4 hours to fully dissolve the polyvinyl alcohol, and prepare a polyvinyl alcohol solution with a mass fraction of po...

Embodiment 2~7

[0058] Embodiments 2-7 respectively provide a preparation method of polypyrrole-coated cattail velvet-based ultra-light biomass porous foam. Compared with Example 1, the difference is that the corresponding process parameters in steps S3-S4 are changed, each The parameter values corresponding to the embodiment are shown in Table 1, and the rest of the steps and parameters are consistent with the embodiment 1, and will not be repeated here.

[0059] Process parameter in table 1 embodiment 2~7

[0060]

[0061]

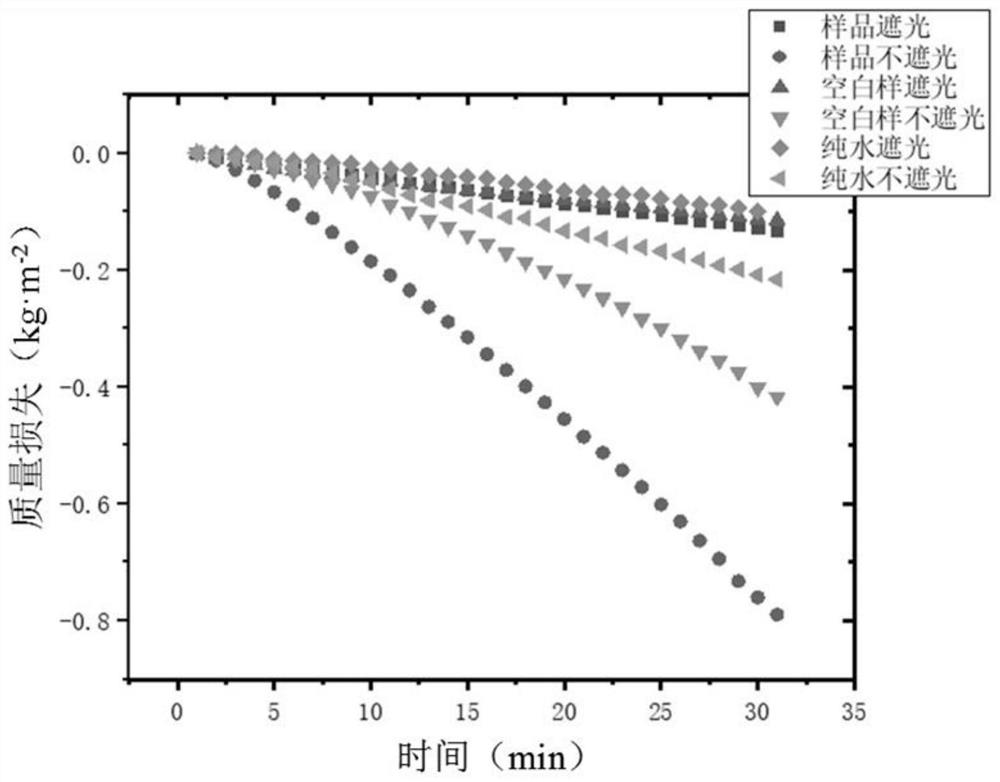

[0062] The evaporation rate of the polypyrrole-coated cattail velvet-based ultralight biomass porous foam prepared in Examples 2-7 was tested, and the results are shown in Table 2.

[0063] Evaporation rate in table 2 embodiment 2~7

[0064] Example evaporation rate Example 2 1.35kg / min Example 3 1.89kg / min Example 4 1.05kg / min Example 5 1.28kg / min Example 6 1.81kg / min Example 7 1.80kg / min

[0065] It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com