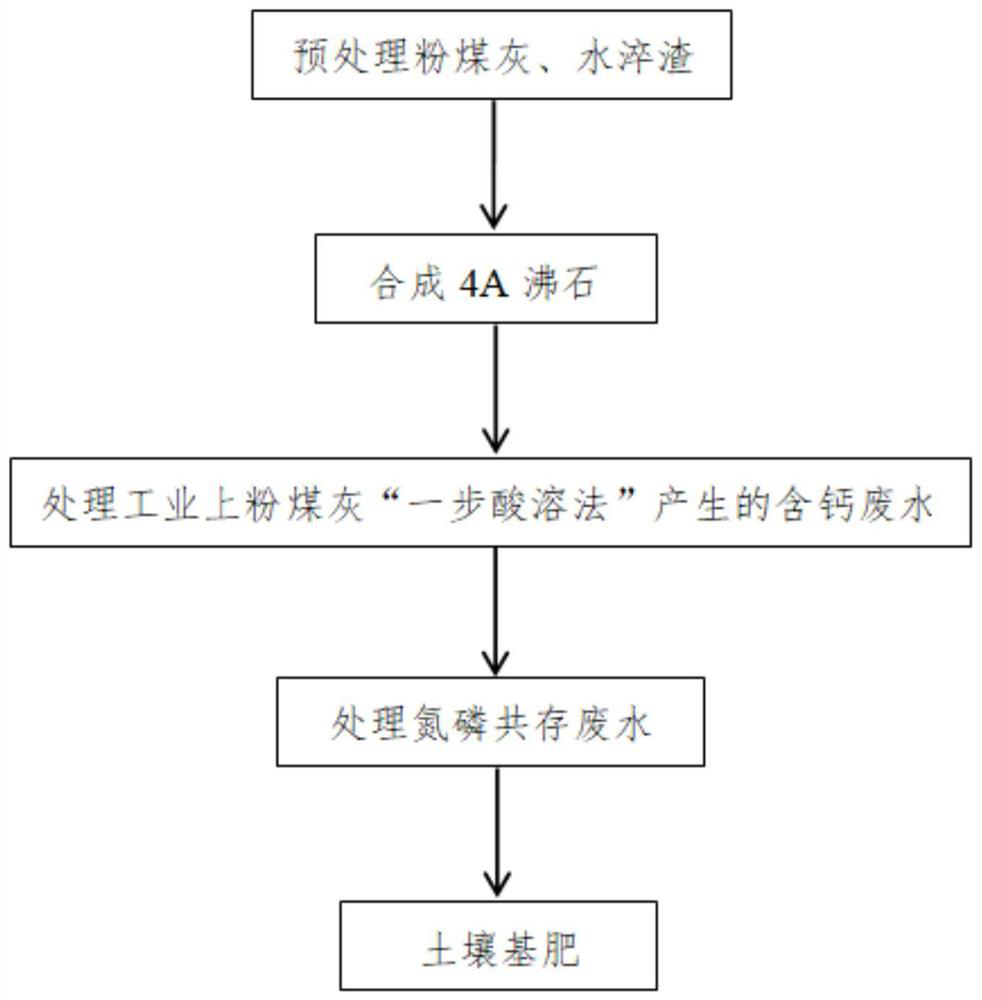

Method for preparing soil base fertilizer by using water-quenched slag and fly ash treatment wastewater

A technology for treating waste water and fly ash, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc. It can solve the problem of few high-value utilization methods, no mention of zeolite regeneration, reuse, and material regeneration Long time and other issues, to achieve ultra-high practical significance and application value, enhance potential utilization value, and improve the effect of overall utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

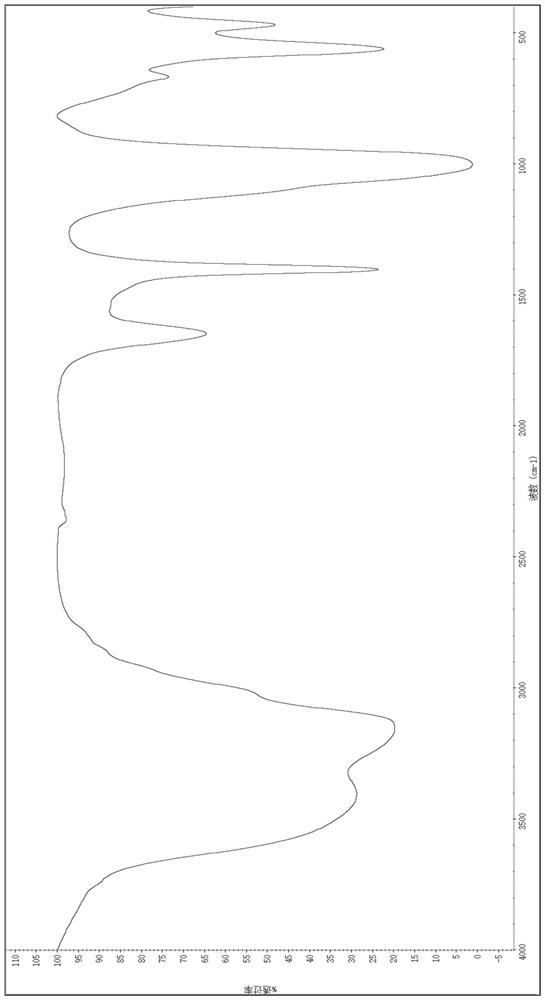

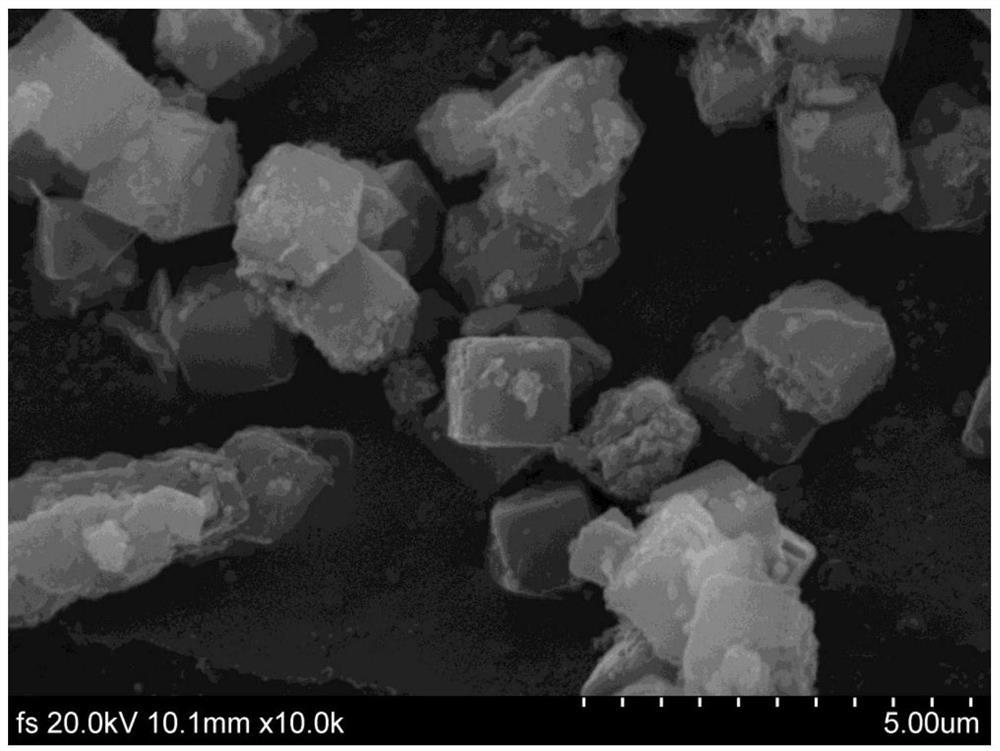

Image

Examples

Embodiment 1

[0041] The 4A zeolite prepared by water quenching slag and fly ash provided by the present invention is used to process calcium-containing wastewater and nitrogen-phosphorus wastewater to make soil base fertilizer. The specific steps are as follows:

[0042] S1, the fly ash composition used in the present embodiment is as follows: SiO 2 62.87%, Al 2 o 3 20.75%, Fe 2 o 3 4.39%, CaO 5.69%, C 1.1%, other 5.2%. The composition of the water-quenched slag used is as follows: SiO 2 34.68%, Al 2 o 3 11.60%, MgO 4.34%, CaO 45.31%, other 4.07%. Firstly, the fly ash and water-quenched slag are pretreated separately: put the fly ash into a beaker with a rotor, add the fly ash and distilled water at a ratio of 1g:5mL, wash with water at a speed of 400r / min for 3h , dried at 100°C for 3 hours, and passed through a 200-mesh sieve; treatment of water-quenched slag: After fully grinding the water-quenched slag in a mortar, passed through a 200-mesh sieve.

[0043] S2. Subsequently,...

Embodiment 2

[0055] Adopt the 4A zeolite prepared in Example 1 to carry out the wastewater treatment link: first, the selected fly ash "one-step acid dissolution method" extracts the calcium-containing wastewater produced by the alumina process, wherein the calcium ion content is 12g / L, and it is processed After the distillation treatment, the volume shrunk to 50% of the original, that is, the calcium ion content became 24g / L. Put 3 g of 4A zeolite prepared in Example 1 into the calcium-containing waste water after the above-mentioned 100 ml distillation treatment, and stir at room temperature for 2 h at a speed of 300 r / min, then put it into a centrifuge at 5000 rpm, and complete solid-liquid separation in 10 min. Add 3 g of new 4A zeolite to the supernatant obtained by centrifugation and repeat the above steps until the calcium ion concentration in the supernatant is detected to be lower than 0.3 g / L, and then the purification of calcium-containing wastewater by zeolite is completed. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com