Preparation method and application of cubic molybdenum nitride

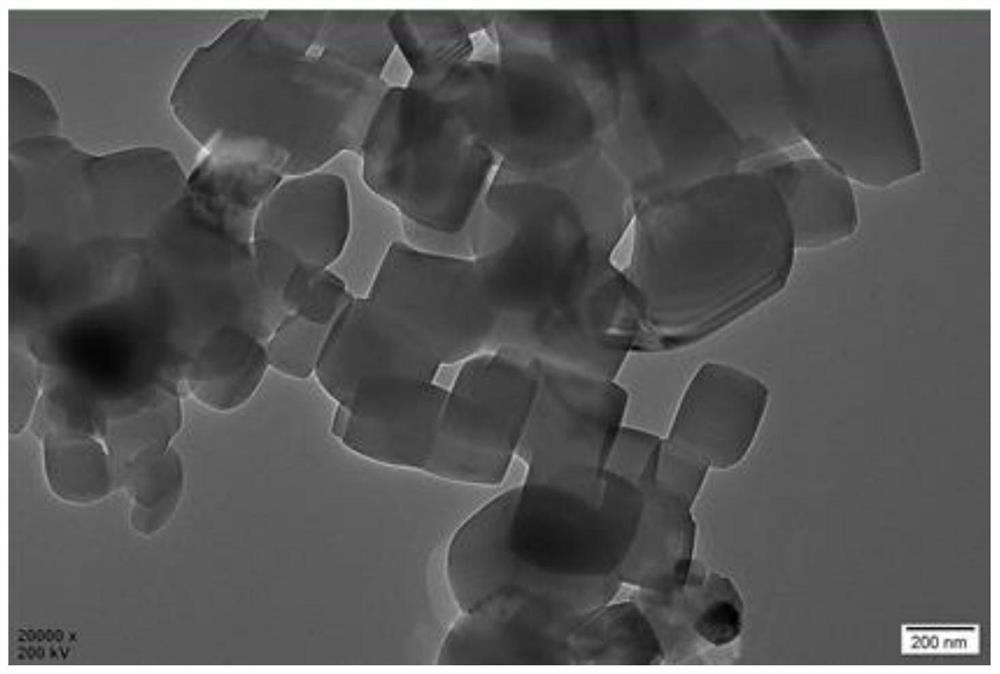

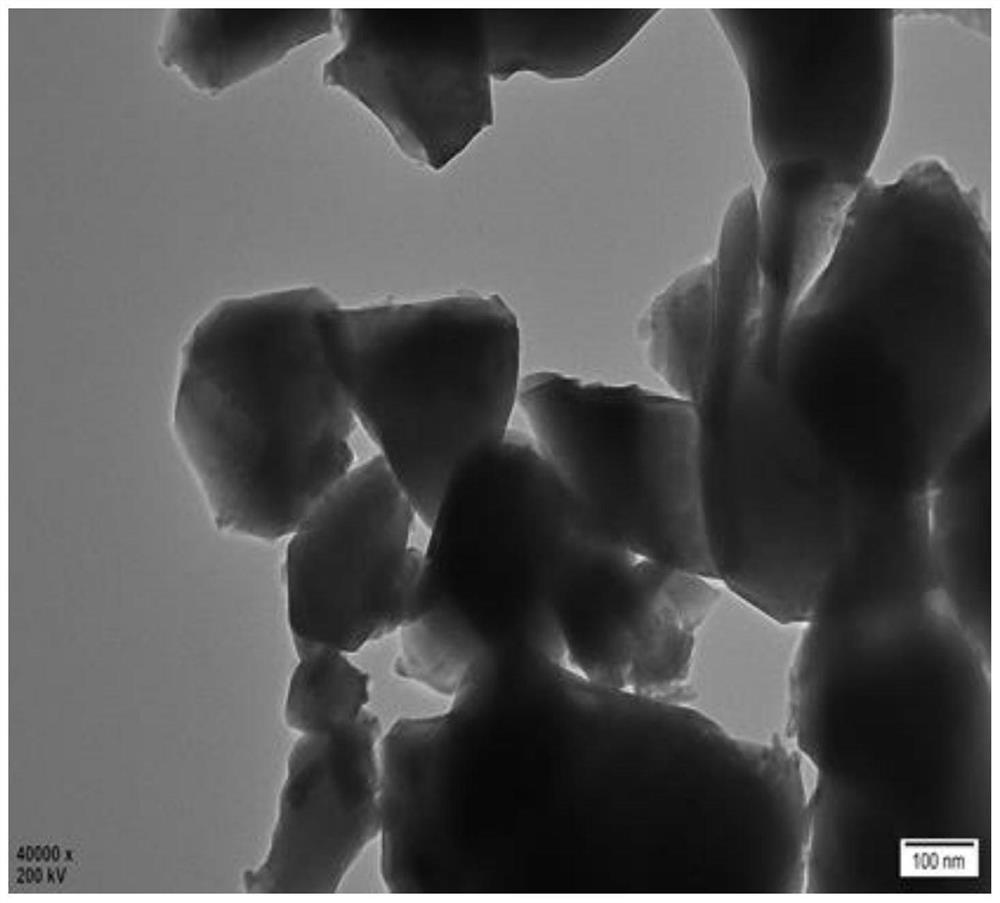

A technology of molybdenum nitride and body shape is applied in the preparation of cube-shaped molybdenum nitride and the application field of negative electrode materials of lithium ion batteries, which can solve the problems of high oxygen content in products, unsuitable molybdenum nitride, long preparation period, etc. Achieve uniform particle size, low equipment requirements, and good crystal morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

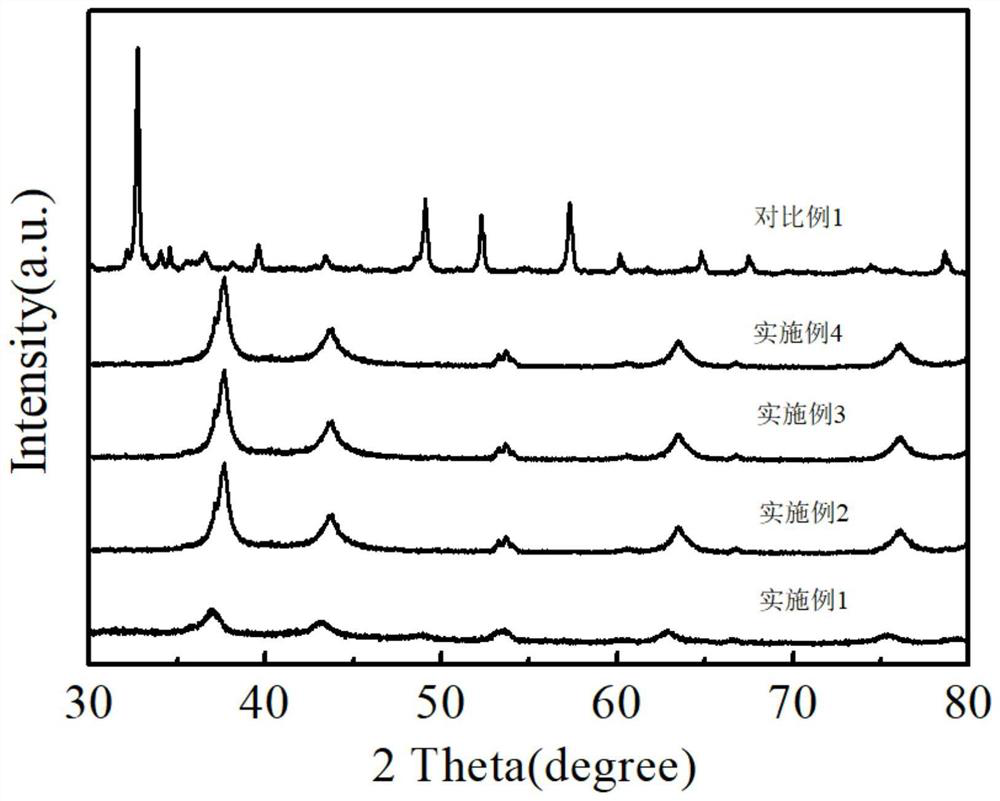

Embodiment 1

[0035] A cubic Mo2 The preparation method of N, its step is as follows:

[0036] 0.5g of ammonium molybdate tetrahydrate, 10g urea and 0.6g melamine are added respectively in the ethanol solution prepared by 24g dehydrated alcohol and 10g distilled water and stirred evenly to obtain respectively the ethanol solution of ammonium molybdate tetrahydrate, the ethanol solution of urea and The ethanol solution of melamine, then the three bottles of solutions were mixed, and the mixed solution was obtained after stirring for 12 hours; the obtained mixed solution was aged at room temperature for 24 hours to form a sol; the obtained product was freeze-dried to form a solid, and then the obtained solid was placed in the air Pre-calcined at 300°C for 2h under the condition, then heat-treated at 400°C for 0.5h, and cooled to room temperature to obtain the precursor powder. The obtained powder was calcined at 700 °C for 2 h under nitrogen atmosphere, and cooled to room temperature to obtai...

Embodiment 2

[0038] A cubic Mo 2 The preparation method of N, its step is as follows:

[0039] The tetrahydrate ammonium molybdate of 0.7g, 10g urea and 0.45g melamine are added respectively in the ethanol solution prepared by 24g dehydrated alcohol and 10g distilled water and stir, obtain the ethanol solution of tetrahydrate ammonium molybdate, the ethanol solution of urea and The ethanol solution of melamine, then the three bottles of solutions were mixed, and the mixed solution was obtained after stirring for 12 hours; the obtained mixed solution was aged at room temperature for 24 hours to form a sol; the obtained product was freeze-dried to form a solid, and then the obtained solid was placed in the air Pre-calcined at 300°C for 2h under the condition, then heat-treated at 400°C for 0.5h, and cooled to room temperature to obtain the precursor powder. The obtained powder was calcined at 800 °C for 2 h under a nitrogen atmosphere, and cooled to room temperature to obtain Mo 2 N electr...

Embodiment 3

[0041] A cubic Mo 2 The preparation method of N, its step is as follows:

[0042] 0.9g of ammonium molybdate tetrahydrate, 10g urea and 0.45g melamine are added respectively in the ethanol solution prepared by 24g dehydrated alcohol and 10g distilled water and stirred evenly, obtain the ethanol solution of ammonium molybdate tetrahydrate, the ethanol solution of urea and The ethanol solution of melamine, then the three bottles of solutions were mixed, and the mixed solution was obtained after stirring for 12 hours; the obtained mixed solution was aged at room temperature for 36 hours to form a sol; the obtained product was freeze-dried to form a solid, and then the obtained solid was placed in the air Pre-calcined at 300°C for 2h under the condition, then heat-treated at 400°C for 0.5h, and cooled to room temperature to obtain the precursor powder. The obtained powder was calcined at 900 °C for 2 h under nitrogen atmosphere, and cooled to room temperature to obtain Mo 2 N el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com