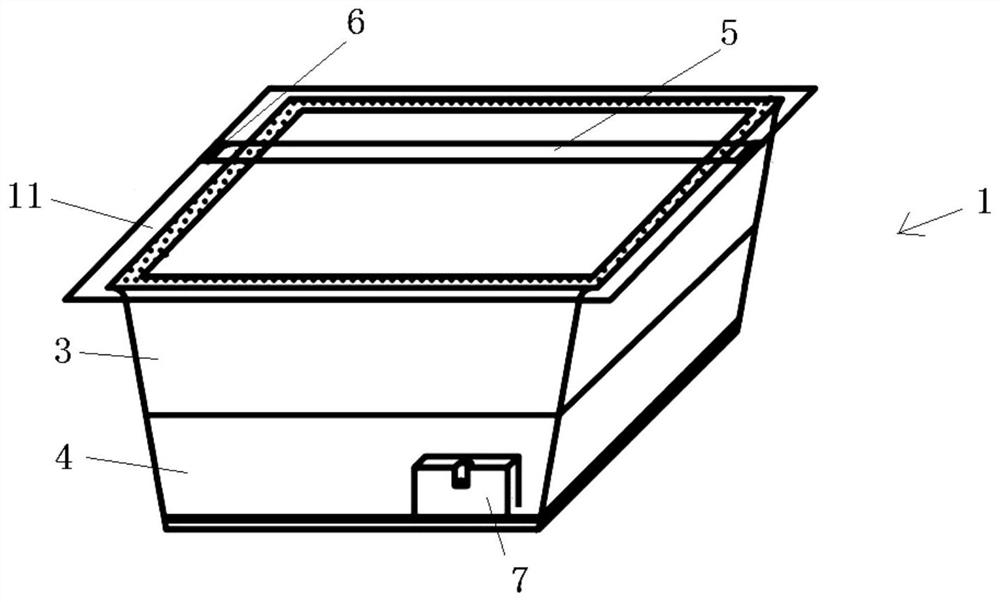

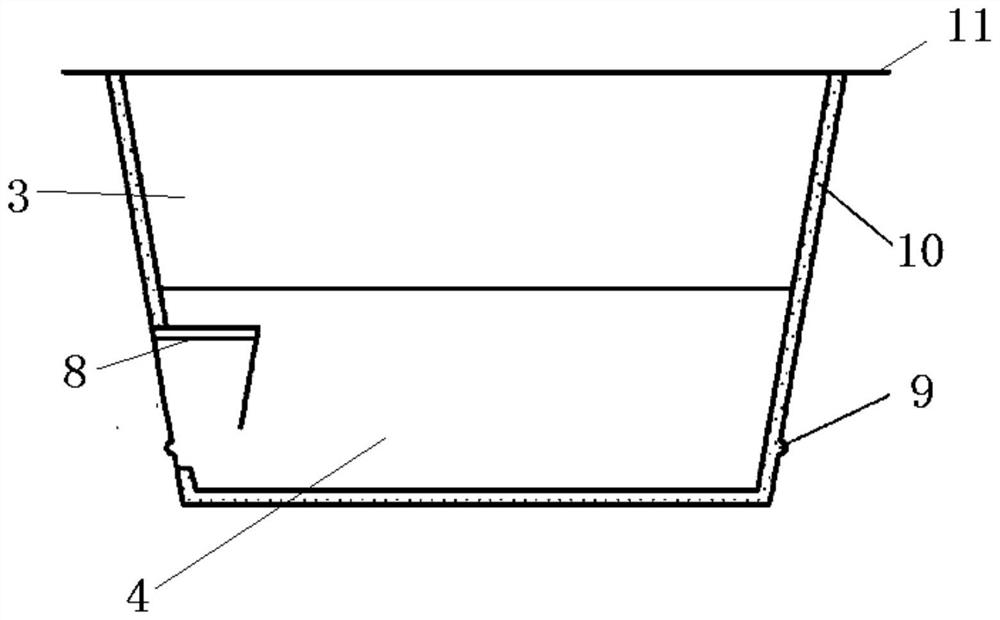

Pressure-controllable steam release packaging box for quick-frozen foods and heating method thereof

A technology for quick-frozen food and packaging boxes, which is applied in the field of quick-frozen food controllable pressure-release steam packaging boxes and its heating. It can solve the problems of single heating method, high frost cracking rate of noodles, and slow production efficiency, and achieve fast heat transfer efficiency. , heat transfer fast, reduce the effect of frost cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

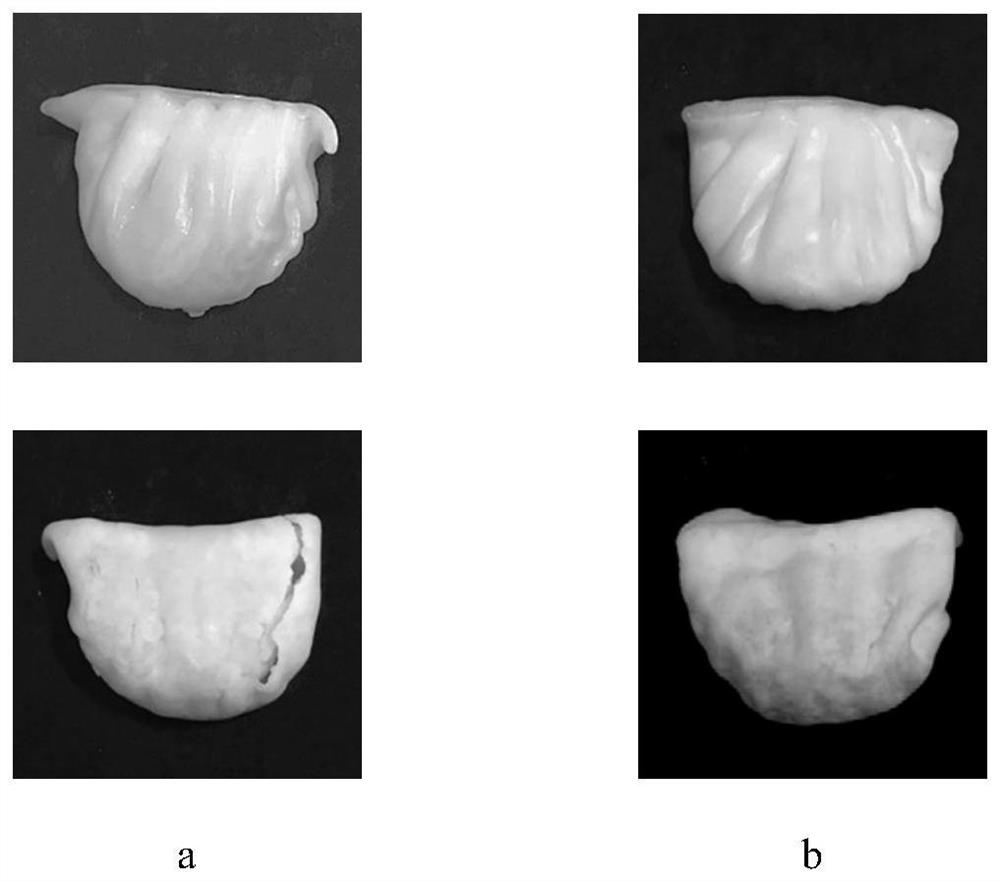

[0062] (1) Take a heating box with a total height of 14cm (the height of the interlayer with holes is 6cm, and the height of the water layer is 8cm), and the size of the box opening is 15×15cm. Put 5 shrimp dumplings (each weighing 20g) in the tray with holes in the box, and the loading density is 0.032g.cm -3 ;The steam volume is 56.25mL.min -1 After pre-steaming for 4 minutes, the volume expansion rate of shrimp dumplings is about 25.4%.

[0063] (2) After quick-freezing, seal the heating box with a steam-release sealing film with a size of 16×16cm. The heat-sealing temperature is 145°C, the heat-sealing time is 2s, and the corresponding steam-release pressure point is 22Kpa; Store in -18°C refrigerator.

[0064] (3) Open the water injection port cover, add water from the water injection port to the water storage layer until the water level is flush with the scale line, and the amount of water added is 40mL;

[0065] (4) Put the heating box after adding water into the mic...

Embodiment 2

[0068] (1) Take a heating box with a total height of 12cm (the height of the interlayer with holes is 5cm, and the height of the water layer is 7cm), and the size of the box opening is 15×15cm. Put 6 small steamed buns (each weighing 15g) in the tray with holes in the box, and the loading density is 0.033g.cm -3 ;The steam volume is 56.25mL.min -1 After pre-steaming for 2 minutes, the volume expansion rate of Xiaolongbao is about 20%.

[0069] (2) After quick freezing, seal the heating box with a steam-release sealing film with a size of 16×16cm. The heat-sealing temperature is 130°C, the heat-sealing time is 3s, and the corresponding steam-release pressure point is 12Kpa; Store in -18°C refrigerator.

[0070] (3) Open the end cover of the water injection port, add water from the water injection port to the water storage layer until the water level is flush with the scale line, and the amount of water added is 35mL;

[0071] (4) Put the heating box after adding water into t...

Embodiment 3

[0074] (1) Take a heating box with a total height of 16cm (the height of the interlayer with holes is 7cm, and the height of the water layer is 9cm), and the size of the box opening is 16×16cm. Put 6 steamed dumplings (each weighing 35g) in the tray with holes in the box, and the loading density is 0.051g.cm -3 ;The steam volume is 56.25mL.min -1 After pre-steaming for 4 minutes, the volume expansion rate of steamed dumplings is about 30%.

[0075] (2) After quick-freezing, take a leakable

[0076] The sealing film seals the heating box, the heat sealing temperature is 160°C, the heat sealing holding time is 3s, and the corresponding steam release pressure point is 35Kpa; after the packaging is completed, put it into a -18°C refrigerator for storage.

[0077] (3) Open the end cover of the water injection port, add water from the water injection port to the water storage layer until the water level is flush with the scale line, and the amount of water added is 70mL;

[0078]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com